Flange Gaskets: The Critical Sealing Assurance for Valve and Pipeline Connections

In various industrial pipeline systems, butterfly Valves and check valves play a vital role in controlling fluid flow direction and on-off, while the important task of ensuring a tight connection between valves and pipelines and preventing medium leakage falls on flange gaskets. As a factory with years of experience in manufacturing butterfly valves and check valves, we have a profound understanding of the importance of flange gaskets.

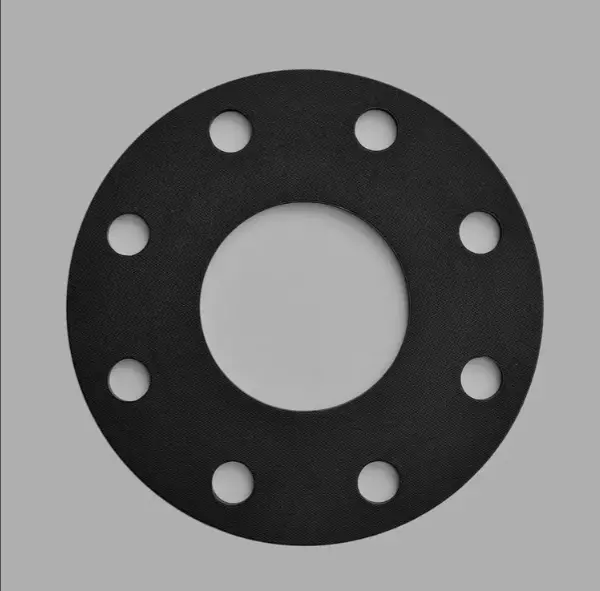

A flange gasket, simply put, is a sealing element filled between the sealing surfaces of two flanges. Its core mission is to fill the miCro-irregularities on the flange surface, forming a tight barrier to prevent the leakage of media such as gases and liquids in the pipeline. Imagine the pipeline system as the blood vessels of the human body, with the medium being the blood flowing through them. If the "connection of blood vessels" - the flange part - lacks reliable sealing and causes medium leakage, it will not only lead to resource waste but may also trigger safety accidents, especially in scenarios where flammable, explosive, toxic, or harmful media are transported.

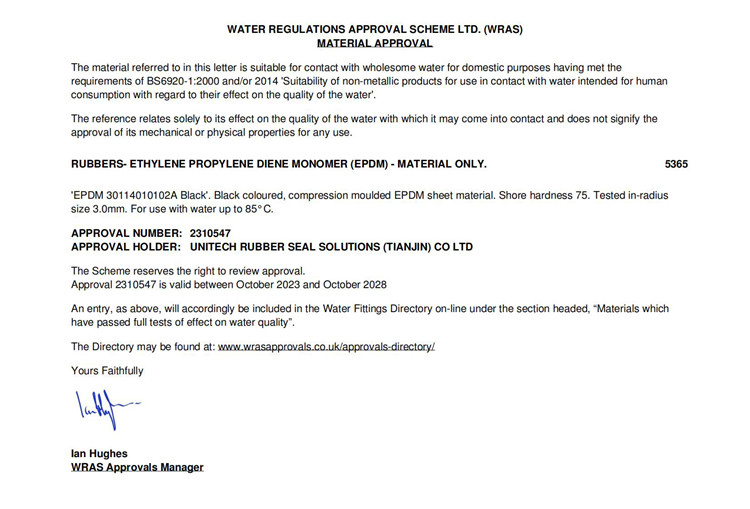

There are many types of flange gaskets to meet different working conditions. Among non-metallic gaskets, rubber gaskets are widely used in low-pressure and normal-temperature water supply and drainage and ventilation systems due to their good elasticity and corrosion resistance. For example, when butterfly valves are used in building air-conditioning water pipelines, they are often paired with rubber gaskets. PTFE (polytetrafluoroethylene) gaskets have excellent chemical corrosion resistance and are the first choice for corrosion-resistant pipelines in the chemical industry, performing well in the connection of check valves for transporting strong acid and alkali media. Semi-metallic gaskets combine the advantages of metal and non-metal materials. For example, spiral wound gaskets are made by winding metal strips with non-metal strips such as graphite and PTFE. They have good compression and rebound performance and can adapt to harsh environments such as high temperature, high pressure, and strong corrosion, frequently appearing in high-temperature steam and high-pressure oil pipelines in industries such as petroleum refining and power. Metal gaskets are suitable for ultra-high pressure and ultra-high temperature working conditions. For example, metal ring gaskets, used in conjunction with ring joint face flanges, are used in high-pressure natural gas transmission pipelines to ensure sealing safety.

In the process of manufacturing butterfly valves and check valves, accurately matching flange gaskets for customers is a key link. According to the medium characteristics (such as corrosiveness, toxicity, flammability and explosiveness), working pressure and temperature of the valve application scenario, as well as the form of the flange sealing surface, the type and material of the gasket are carefully selected. For example, for butterfly valves transporting corrosive media in chemical enterprises, we select PTFE-clad gaskets or corrosion-resistant spiral wound gaskets; for check valves on high-temperature and high-pressure steam pipelines, we equip high-temperature-resistant metal gaskets.

Correct installation of flange gaskets is also important. During installation, it is necessary to ensure that the flange sealing surface is clean and free of impurities, the gasket is accurately positioned, and the bolts are tightened symmetrically and evenly to achieve appropriate preload, which not only ensures the sealing effect but also avoids damage to the gasket due to excessive compression.

In short, although flange gaskets are small, they are a key part to ensure the stable and safe operation of the pipeline system where butterfly valves and check valves are located. Our factory will continue to pay attention to the development of gasket technology to provide customers with better and more suitable valve and gasket solutions.