Check Valve: The "One-Way Guardian" in Pipelines

In the complex world of pipelines, there is a silent "one-way guardian" at work — the check valve. Unlike the roaring water pump or the imposing gate Valve, the "big brother" of the valve family, it safeguards the order of the fluid world with its unique "personality."

The core ability of a check valve is to make fluids "only go forward, never backward."

Different types of check valves have their own "special skills":

- The swing check valve is like a "swing door." When water flows, it automatically pushes the "door" open; when backflow occurs, the "door" slams shut. It is suitable for large-diameter water pipes.

- The lift check valveis more like a "small piston." The water flow pushes the piston upward, and when backflow occurs, the piston falls steadily. It is most commonly seen in tap water pipelines.

-

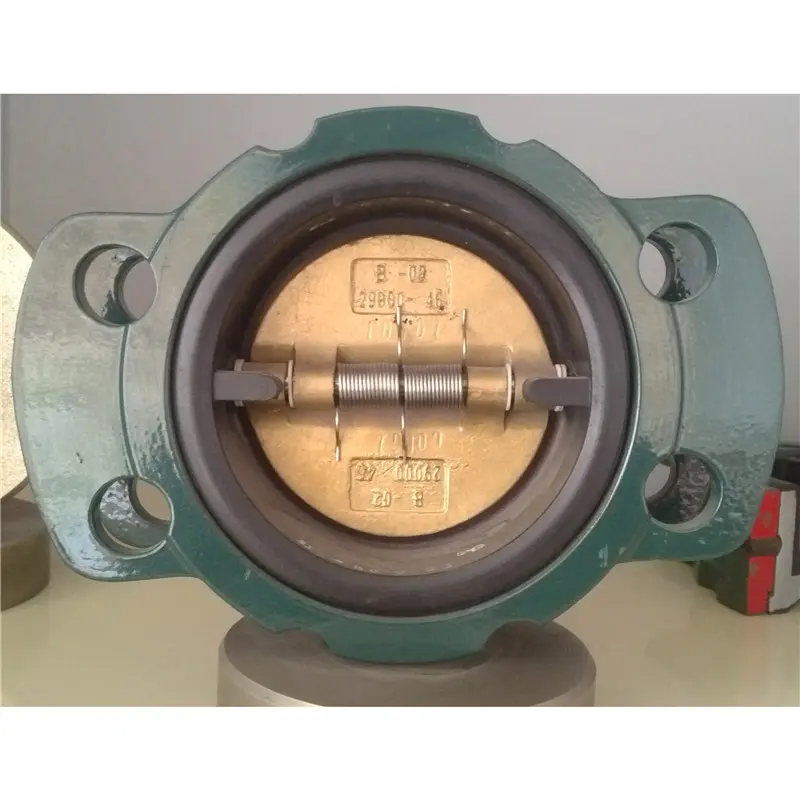

The spring-loaded check valverelies on the elastic force of a spring to "guard the pass." Even if the water flow speed changes rapidly, it can tightly lock the "stEps" of backflow, making it particularly reliable in high-pressure pipelines.

In our daily lives, check valves are everywhere — in home water purifiers and toilet tanks, hospital oxygen supply systems, factory steam pipelines... Wherever there is fluid flow, they silently "stand guard." With their small bodies, they take on the heavy responsibilities of preventing backflow, protecting equipment, and stabilizing systems. Like "invisible heroes" in the pipeline world, they use their persistent "one-way guardianship" to ensure that every drop of water and every wisp of air follows the correct direction to their intended destinations.