In the evolving landscape of industrial applications, innovations in rubber seals have become a focal point. These critical components ensure optimal performance and durability across various sectors. As industries face new challenges, the need for advanced rubber seal technology has never been greater.

Take the automotive industry, for example. It demands seals that withstand extreme conditions. Yet, there are often gaps in quality and performance. Addressing these issues is essential. The development of advanced rubber seals can lead to superior solutions, enhancing longevity and efficiency.

The potential of rubber seals extends to many industries. From manufacturing to construction, their versatility is clear. However, innovation must address the flaws that exist in current products. Striving for better materials and designs is crucial. In this exploration of the top rubber seal innovations for 2026, we will uncover these advancements and the impact they may have on your industry needs.

Rubber seals play a pivotal role across various industries. They ensure that products function efficiently and remain protected. Many innovations in rubber seal technology have emerged recently. These innovations focus on durability, flexibility, and environmental sustainability, which are becoming crucial needs for modern industries.

In the automotive sector, innovative rubber seals keep environments inside vehicles quiet and comfortable. They combat noise and vibration effectively. In the food processing industry, seals are now designed to withstand high temperatures and aggressive cleaning agents. This enhances safety and ensures compliance with health regulations. However, not all seal innovations are perfect. Some may wear out faster than expected, leading to potential leaks and failures.

The aerospace industry also benefits from advanced rubber seal designs. These seals must endure extreme conditions. Yet, challenges remain in balancing weight and durability. Developing seals that are lighter but still effective is an ongoing concern. As technology progresses, continuous evaluation and improvement are essential to meet industry demands.

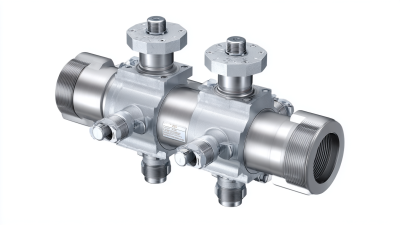

In the evolving landscape of rubber seal innovations, materials play a pivotal role. Synthetic rubbers, such as EPDM and silicone, are frequently utilized. These materials offer resistance to extreme temperatures and chemical exposure. You can find them in a wide range of applications, from automotive to industrial machinery.

Another key player is fluorosilicone. This material excels in environments with fuel exposure. It maintains durability and flexibility. Choosing the right material can greatly enhance performance in your specific industry. Consider your operational environment carefully.

Tips: Always check environmental resistance before selecting a seal. Don’t overlook the influence of temperature on rubber performance. Sometimes testing multiple materials leads to the best fit. Remember, not every solution is perfect. It may take several iterations to achieve optimal results.

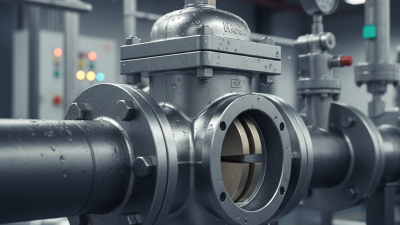

Advanced rubber seals have a wide range of applications across various sectors. In the automotive industry, these seals play a critical role. They help prevent leaks in engines and transmissions. Their resilience under extreme temperatures is vital for vehicle performance. Enhanced durability results in fewer replacements, saving costs.

In the construction sector, rubber seals ensure the integrity of structures. They are used in windows and doors to provide insulation. This contributes to energy efficiency and reduces noise pollution. However, choosing the right seal can be challenging. The wrong material might not withstand environmental conditions.

The food and beverage industry also relies on rubber seals. They ensure hygiene and safety in food processing. The seals keep contaminants out of products. Yet, regular inspections are necessary. Wear and tear can lead to contamination risks, highlighting the importance of quality checks. Identifying potential risks is crucial for maintaining standards.

This bar chart illustrates the market adoption rates of advanced rubber seal innovations across various industry sectors in 2026. The automotive sector leads with a 75% adoption rate, indicating strong integration of new technologies, while the aerospace and medical sectors also show significant engagement. Consumer goods exhibit the lowest adoption at 45%, reflecting potential growth areas for future advancements.

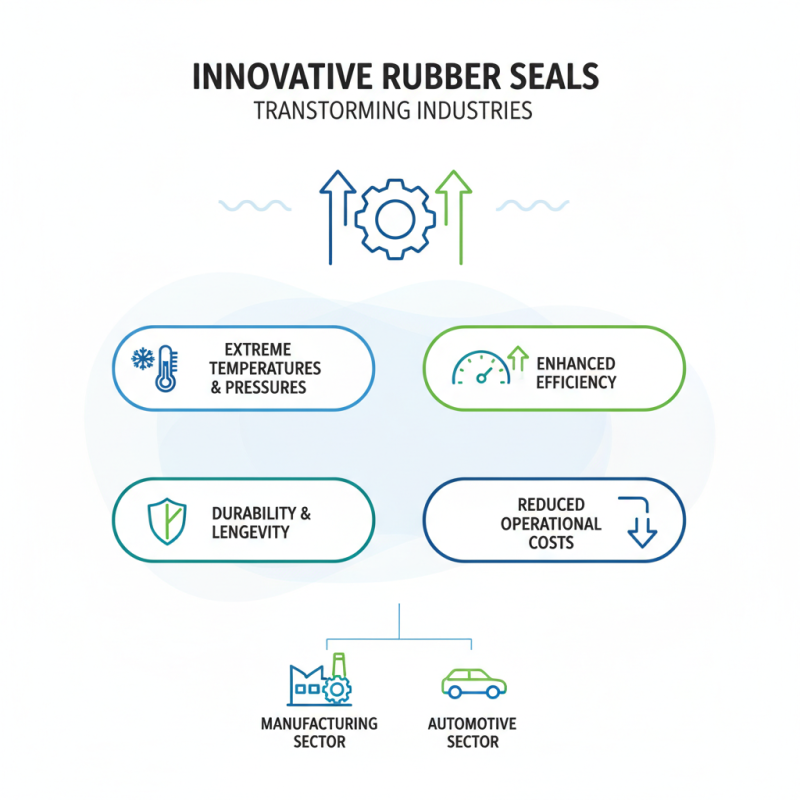

Innovative rubber seals are transforming various industries. They enhance efficiency and reduce operational costs. These seals can withstand extreme temperatures and pressures. Their durability makes them ideal for many applications. This is particularly important in manufacturing and automotive sectors.

Implementing these seals may initially seem costly. However, the long-term benefits outweigh the expenses. Businesses often see reduced maintenance needs, leading to lower downtime. Innovative rubber seals also lead to better energy efficiency. As a result, companies can minimize their environmental impact.

Several companies struggle with selecting the right materials. Experimenting with options can create uncertainty. It’s essential to evaluate each application thoroughly. User feedback is invaluable. Listening to front-line workers often reveals critical insights. This can lead to discovering the best sealing solutions for specific needs.

The future of rubber seal innovations holds exciting potential. As industries evolve, the need for advanced sealing solutions grows. Future rubber seals may incorporate nanotechnology. This could lead to enhanced durability and flexibility.

Sustainability is becoming crucial. Eco-friendly materials could dominate the market. The push for biodegradable seals reflects growing environmental awareness. Companies might face challenges sourcing these sustainable materials. Testing and validation can be complex and time-consuming.

Moreover, smart rubber seals could emerge. These seals might be embedded with sensors to monitor performance. Real-time data could prevent leaks and minimize failures. However, integrating technology presents its own set of hurdles. Balancing the benefits with costs is essential for companies.