In the world of manufacturing, Rubber Molding plays a crucial role. Experts like Dr. Emily Tan, a leading figure in the rubber industry, emphasize, "Every method has its unique advantages and challenges." Understanding these nuances can greatly enhance product quality and efficiency.

Rubber Molding techniques are varied and each offers specific benefits. For instance, compression molding is simple yet effective, while injection molding allows for high precision. Manufacturers often grapple with choosing the most suitable method, as each technique presents its own set of pros and cons. This decision can impact production costs and lead times significantly.

While the top rubber molding techniques promise innovation, they also require constant learning and adjustment. Techniques evolve and not every approach may work for every application. Keeping an open mind is essential. By reflecting on past choices and outcomes, companies can navigate the complexities of Rubber Molding more effectively. Understanding these ten techniques will provide a strong foundation for better decision-making in product development.

Rubber molding techniques are essential for various industries. They enable the production of durable rubber parts. Understanding these methods is crucial for manufacturers. Here are some notable techniques.

Compression molding is commonly used. It involves placing rubber in a heated mold. The pressure causes it to take the mold's shape. However, it can lead to material wastage if not executed correctly. Proper measurement is vital.

Injection molding is another technique. In this method, rubber is injected into the mold under pressure. This provides detailed shapes and consistent quality. Yet, it requires precise temperature control. Any fluctuations can affect results.

Tips: Always test your mold designs first. Small errors can lead to significant faults in the final product. Keep an eye on the rubber temperature during shaping. Too high or too low can ruin your batch. Regular maintenance of equipment ensures longevity. Small issues can escalate quickly, so stay proactive.

Compression molding is a widely used technique in the rubber molding industry. This process starts with placing raw rubber into a heated mold. The heat causes the rubber to become pliable, making it easier to shape. Then, the mold is closed, applying pressure to ensure the rubber fills every cavity. This method is efficient for mass production. It's cost-effective for creating various rubber parts.

Despite its advantages, compression molding has its challenges. Achieving uniform thickness can be difficult. Variations in temperature or pressure may lead to defects. Inconsistent mold filling can also result in weaker parts. It's crucial to monitor the process carefully. Knowing when to adjust parameters is vital for quality control. Each molding cycle requires attention to detail.

Learning compression molding takes practice. Newcomers often struggle with timing and material handling. Mistakes can lead to wasted materials and time. Continuous improvement is necessary in mastering this technique. Understanding the basics allows for better decision-making in future projects. Embracing these challenges can lead to innovation in design and production.

| Technique | Description | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Compression Molding | A method where rubber is placed in a heated mold before being compressed into shape. | Seals, gaskets, and automotive parts. | Cost-effective for large parts, minimal waste. | Long cycle times, less control over part dimensions. |

| Transfer Molding | Rubber is preheated and transferred into a mold cavity. | Electrical components, custom rubber parts. | Better control of part quality, reduced cycle times. | Higher costs due to equipment and materials. |

| Injection Molding | Molten rubber is injected into a mold to form parts. | Consumer goods, automotive components. | Highly efficient for large runs, precision parts. | High tooling costs, limited to thermoplastic rubbers. |

| Blow Molding | Air is blown into a tube of molten rubber to create hollow parts. | Bottles, tanks, and inflatable products. | Rapid production of hollow forms, lightweight products. | Not suitable for all shapes, limited thickness control. |

| Vacuum Molding | Uses vacuum pressure to assist in shaping rubber sheets into molds. | Protective pads, custom fit products. | Good for low-volume production, flexible design. | Slower production speed, limited material types. |

| Lamination | Layering rubber with other materials to create composite products. | Automotive seats, shock absorbent materials. | Combines properties, enhanced performance. | Complex process, can be costly. |

| Extrusion Molding | Rubber is shaped into continuous profiles through a die. | Weather stripping, seals, tubing. | Efficient for long runs, consistent shapes. | Limited to cross-sectional shapes, excess material. |

| Rotational Molding | Rotating mold fills with a powdered material that melts and coats the interior. | Large parts like tanks and playground equipment. | Versatility in size and shape, seamless parts. | Longer cycle times, not as efficient for small batches. |

| Thermoforming | Heating rubber sheets and forming them into specified shapes. | Packaging, automotive trim, consumer products. | Cost-effective for low to medium runs, versatile. | Limited to certain designs, risk of overheating. |

| Cold Molding | Forming rubber parts at room temperature. | Sealants, adhesives. | Energy-efficient, less equipment required. | Longer curing times, potential for defects. |

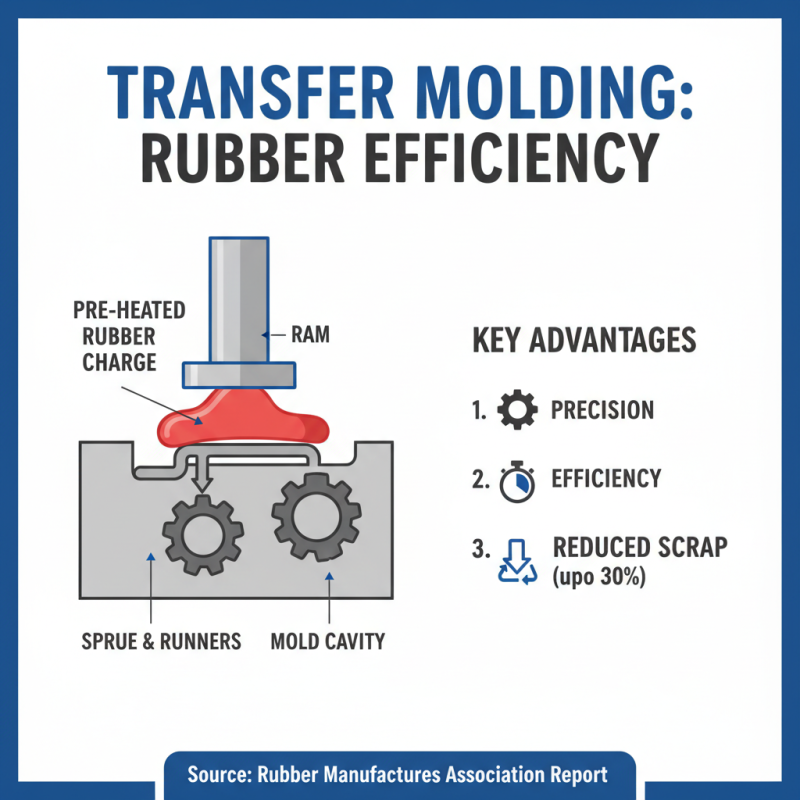

Transfer molding is a popular technique in the rubber molding industry. It involves using a pre-measured amount of rubber that is heated and then forced into a mold cavity. This method has several advantages, including precision and efficiency. According to a recent report by the Rubber Manufacturers Association, transfer molding can reduce scrap rates by up to 30% compared to other methods.

One significant application of transfer molding is in the automotive sector. Many automotive components, such as seals and gaskets, are produced using this technique. The ability to create complex shapes with tight tolerances makes it ideal for these parts. However, it's essential to consider the limitation in production speed. Transfer molding can be slower than other methods like injection molding.

Another disadvantage is the initial setup cost. The molds can be expensive and time-consuming to create. Despite these challenges, the benefits often outweigh the disadvantages. In fact, companies often report a return on investment within a year of switching to transfer molding. It’s a viable option for specialized rubber products needing high-quality finishes.

Injection molding stands out as one of the most efficient techniques for rubber production. This method allows for mass production with precision and minimal waste. According to industry reports, the efficiency of injection molding can reduce production costs by up to 30%. This is largely due to shorter cycle times and lower labor costs involved in the process.

Tips: Always ensure your molds are well-maintained. This can prevent defects and increase production speed. Frequent inspections can save time and money in the long run.

Despite its advantages, injection molding isn't without challenges. The process requires significant upfront investment in tooling. For small production runs, this can lead to financial strain. Additionally, improper temperature control can affect rubber quality, resulting in inconsistent products.

Tips: Monitor temperature closely during production. A minor fluctuation can lead to major quality issues. Consider using data logging tools for precision.

In conclusion, injection molding is a powerful method for rubber production but requires careful management. Making informed decisions about tooling and production conditions is key to success in this field.

Blow molding is a fascinating technique used to create hollow rubber parts. This process involves inflating a heated piece of rubber into a mold. Air is blown inside, expanding the rubber against the mold’s interior. The result is a lightweight and durable product with a seamless design.

One of the challenges in blow molding is achieving uniform thickness. If the material is too thin, it may not provide the needed strength. Conversely, excessive thickness can lead to unnecessary weight. The balance is tricky and requires careful monitoring. Unfortunately, many manufacturers overlook this detail.

Designing molds for blow molding can also be complicated. It involves precision engineering to ensure quality output. Misalignments can result in defects, ultimately leading to failed products. This highlights the need for continual assessment and adjustments in the molding process. Simple changes can lead to major improvements. Understanding these intricacies is key to mastering blow molding.