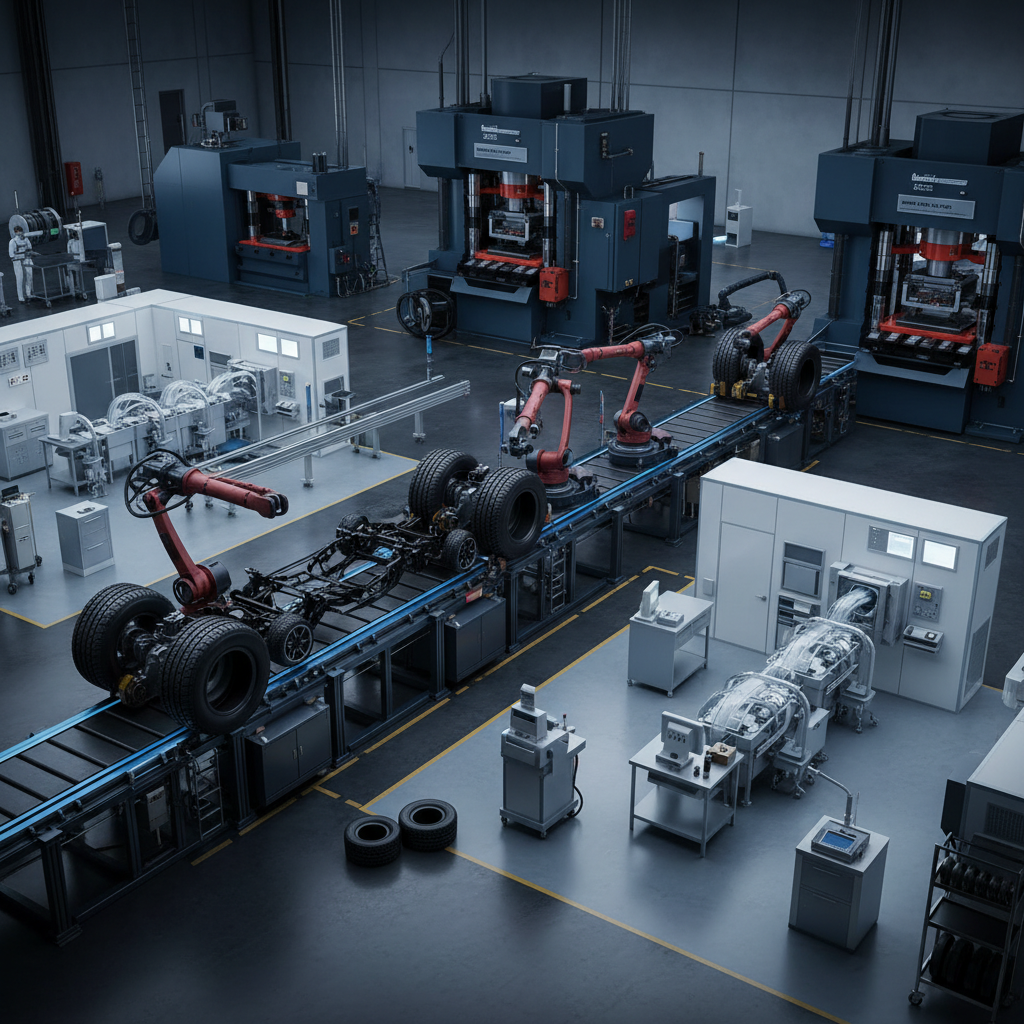

Vulcanized rubber, a revolutionary material resulting from the chemical process of vulcanization, has fundamentally transformed manufacturing applications across various industries. According to a report by Grand View Research, the global rubber market size was valued at USD 41.7 billion in 2020, with vulcanized rubber dominating a substantial portion due to its exceptional durability and resilience. The tire manufacturing sector alone accounts for over 60% of overall rubber consumption, underscoring the material’s critical role in enhancing product performance and longevity.

Vulcanized rubber, a revolutionary material resulting from the chemical process of vulcanization, has fundamentally transformed manufacturing applications across various industries. According to a report by Grand View Research, the global rubber market size was valued at USD 41.7 billion in 2020, with vulcanized rubber dominating a substantial portion due to its exceptional durability and resilience. The tire manufacturing sector alone accounts for over 60% of overall rubber consumption, underscoring the material’s critical role in enhancing product performance and longevity.

In addition to the automotive industry, vulcanized rubber is increasingly utilized in diverse manufacturing settings, including consumer goods, healthcare, and industrial components. A study by Smithers Pira highlights that the demand for high-performance rubber materials is expected to grow at a CAGR of 4.4% through 2025, propelled by advancements in manufacturing technology and increased application versatility. This growth emphasizes the necessity for manufacturers to leverage the unique benefits of vulcanized rubber, which not only improves product quality but also enhances operational efficiency. As we delve into the top five benefits of using vulcanized rubber in manufacturing, it becomes evident that this material is not merely a choice but a strategic advantage in today’s competitive landscape.

Vulcanized rubber has revolutionized the manufacturing industry due to its remarkable durability and longevity. According to a report by the Rubber Manufacturers Association, vulcanized rubber can withstand temperatures ranging from -60°C to 150°C, ensuring operational efficiency across various environments. This thermal stability significantly reduces the risk of material breakdown, making it an ideal choice for seals, gaskets, and components in machinery that face extreme conditions.

Moreover, the resilience of vulcanized rubber against wear and tear is backed by statistics from the International Institute of Synthetic Rubber Producers. Their findings indicate that products made from vulcanized rubber can last up to three times longer than those constructed from non-vulcanized materials. This superior performance not only minimizes the frequency of replacements but also reduces maintenance costs, leading to enhanced overall productivity. As manufacturers continue to seek reliable materials that offer both performance and cost-effectiveness, vulcanized rubber's advantages become increasingly indispensable in a competitive market.

| Benefit | Description | Impact on Manufacturing | Longevity |

|---|---|---|---|

| High Durability | Vulcanized rubber is resistant to wear and tear. | Reduces the need for frequent replacements, minimizing downtime. | Lasts significantly longer than non-vulcanized rubber. |

| Temperature Resistance | Able to withstand extreme temperatures without losing integrity. | Maintains performance in various manufacturing environments. | Enhanced lifespan in fluctuating temperature conditions. |

| Chemical Resistance | Resistant to oils, fuels, and many chemicals. | Enables use in diverse industrial applications without degradation. | Prolongs life in harsh environments. |

| Enhanced Mechanical Properties | Improves elasticity, tensile strength, and flexibility. | Contributes to quality and performance of manufactured products. | Supports prolonged usage without material failure. |

| Cost-Effectiveness | Initial higher costs offset by longevity and reduced maintenance. | Lower overall production and operational costs. | Long-term savings in material and labor costs. |

Vulcanized rubber has become a staple in manufacturing due to its exceptional adaptability across various applications. One of the primary advantages of vulcanized rubber is its ability to maintain flexibility under a wide range of temperatures and conditions. This flexibility allows manufacturers to use this material in diverse products, from automotive parts to consumer goods, ensuring durability while accommodating the specific demands of each application.

Moreover, the enhanced flexibility of vulcanized rubber enables it to withstand repeated stress and deformation. This resilience is particularly beneficial in industries where components face constant movement or pressure. By employing vulcanized rubber, manufacturers can create products that not only perform better but also have a longer lifespan, reducing the need for frequent replacements. This adaptability ultimately contributes to cost savings and improved efficiency in production processes.

Vulcanized rubber has emerged as a cost-effective material in various manufacturing applications due to its enhanced durability and resilience. The vulcanization process, which involves combining rubber with sulfur and heat, significantly improves its mechanical properties. This results in a material that not only lasts longer but also requires less frequent replacement. For manufacturers, this translates to reduced downtime and lower long-term costs associated with both material procurement and maintenance.

Moreover, vulcanized rubber can withstand harsh environmental conditions, including extreme temperatures and chemical exposure. This robustness allows companies to use it in a wider range of applications without the risk of degradation. While the initial investment in vulcanized rubber may be higher compared to other materials, the savings on maintenance and replacement over time make it a financially savvy choice for many manufacturers.

By choosing vulcanized rubber, businesses can optimize their production processes, enhance product longevity, and ultimately improve their bottom line.

Vulcanized rubber has gained prominence in manufacturing applications due to its exceptional heat and chemical resistance, which provides a significant performance edge. This innovative material undergoes a chemical process that enhances its durability, transforming it into a robust option suitable for high-stress environments, particularly in the automotive industry. As demand for high-performance rubber rises, the vulcanization market is projected to grow, driven by the need for materials that can withstand extreme conditions without compromising functionality.

The ability of vulcanized rubber to resist heat and chemicals makes it invaluable in various industrial applications. Its performance in automotive components—where exposure to engine heat and chemical substances is common—illustrates its critical role in ensuring longevity and safety. With the global elastomers market also on an upward trajectory, reaching an expected USD 148.32 billion by 2033, manufacturers are increasingly recognizing the benefits of integrating vulcanized rubber into their production processes, underscoring its essential contribution to modern manufacturing.

The emphasis on sustainability within manufacturing, particularly in the rubber industry, is gaining traction as companies seek to reduce their environmental impact.

Vulcanized rubber, with its enhanced durability and versatility, is increasingly integrated with renewable materials and innovative processes. Recent advancements have showcased the potential of bio-circular materials, achieving significant reductions in carbon emissions while ensuring the mechanical performance expected from traditional rubber products.

Moreover, the introduction of sustainable rubber additives marks a pivotal shift toward eco-friendliness in tire production. With an increasing focus on greener manufacturing processes, tire manufacturers are exploring the integration of renewable resources and more responsible recycling technologies.

The pursuit of alternatives to petroleum-based components, such as the utilization of biomass or innovative nanocomposites, reflects the industry's commitment to minimizing its ecological footprint while meeting the growing demand for sustainable products.

This alignment with sustainability principles not only addresses environmental challenges but also opens new avenues for innovation within the rubber manufacturing sector.