Silicone gaskets play a crucial role in various industrial and commercial applications due to their excellent sealing properties and resistance to extreme temperatures and harsh environments. According to a report by MarketsandMarkets, the global gasket market is expected to reach USD 70.2 billion by 2025, with silicone gaskets leading the growth due to their versatility and durability. This upward trend highlights the increasing demand for materials that can withstand high pressures and thermal fluctuations, making silicone gaskets a preferred choice in industries ranging from automotive to aerospace and electronics.

The functionality of silicone gaskets is rooted in their unique chemical composition, which provides exceptional flexibility and compressibility. As reported by the Adhesive and Sealant Council, the ability of silicone gaskets to maintain their sealing capabilities across temperature ranges from -60°C to 300°C (with some specialized formulations exceeding these limits) enhances their application in critical areas such as HVAC, pharmaceutical, and food processing sectors. Furthermore, the FDA approval status of many silicone gasket formulations ensures compliance with safety standards in food and medical applications, underscoring their significance in ensuring operational efficiency and safety.

In summary, the profound impact of silicone gaskets across diverse applications can be attributed to their material properties and the ongoing innovation within the gasket industry. As businesses continue to prioritize reliability and efficiency, the demand for silicone gaskets is predicted to grow, making them indispensable in modern manufacturing and engineering solutions.

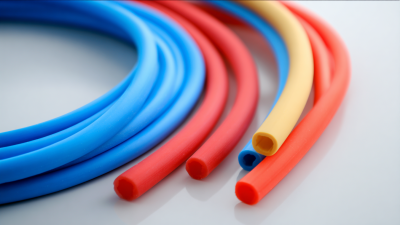

Silicone gaskets are essential components in various industries due to their unique chemical composition and versatility. Made primarily from silicone polymer, these gaskets exhibit excellent thermal stability, resistance to extreme temperatures ranging from -70°C to 230°C, and remarkable flexibility.

According to a report by the Markets and Markets research firm, the global market for silicone materials is projected to reach $18.74 billion by 2027, reflecting an increase in demand for robust sealing solutions in sectors such as automotive and aerospace.

The composition of silicone gaskets typically includes a mix of silicone elastomers, fillers, and additives that enhance their performance characteristics. A comprehensive analysis by Grand View Research highlights that the use of silicone gaskets in the automotive industry constitutes a significant segment, with an expected growth rate of over 5% annually.

This growth can be attributed to the increasing need for lightweight and durable materials that can withstand harsh environments while maintaining effective sealing properties. Thus, silicone gaskets are not only pivotal in ensuring the integrity of machinery and equipment but are also crucial for improving energy efficiency across various applications.

Silicone gaskets play a crucial role in sealing and insulation across various applications due to their unique properties. These gaskets, made from silicone rubber, offer excellent resistance to extreme temperatures, humidity, and chemical exposure. As a result, they are commonly used in automotive, aerospace, and industrial settings where reliability is paramount. Their flexibility allows them to form a tight seal between surfaces, preventing leaks and ensuring that environmental factors do not compromise the integrity of the system.

In addition to their sealing capabilities, silicone gaskets provide exceptional insulation properties. They are often employed in electrical equipment to prevent short circuits and ensure safe operation. Their ability to maintain performance under high temperatures makes them ideal for applications that involve heat generation, such as HVAC systems and engines. By effectively minimizing heat transfer and fostering energy efficiency, silicone gaskets contribute significantly to the performance and longevity of various machinery and systems.

| Application | Material Properties | Temperature Range (°C) | Common Uses |

|---|---|---|---|

| Automotive | High flexibility, resistant to oils | -60 to 250 | Engine components, gaskets |

| Electrical | Electrical insulator, heat resistant | -40 to 200 | Sealing in electrical enclosures |

| Food Industry | Non-toxic, FDA compliant | -40 to 150 | Food processing equipment seals |

| Construction | Weather resistant, UV stable | -50 to 200 | Window seals, roofing |

| Aerospace | Lightweight, vibration resistant | -55 to 220 | Seals for aircraft components |

Silicone gaskets are widely utilized across various industries due to their excellent thermal stability, flexibility, and resistance to many chemicals. In the automotive sector, for instance, silicone gaskets are crucial for sealing engine components. According to a report by MarketsandMarkets, the automotive gasket market is projected to reach $5.6 billion by 2025, with silicone gaskets capturing a significant share due to their ability to withstand high temperatures and pressures, thereby ensuring effective seal integrity under demanding conditions.

In the pharmaceutical and food processing industries, silicone gaskets play a vital role in maintaining sanitary conditions. They provide a reliable barrier against contamination while being compliant with regulations such as FDA standards. A report from Grand View Research highlights that the global food and beverage processing market is expected to grow to $4.3 trillion by 2026, largely driven by the need for reliable sealing solutions that ensure product safety. The durability of silicone gaskets contributes to their longevity, reducing maintenance costs and downtime in these critical applications.

Silicone gaskets have become increasingly popular in various industries due to their unique properties that surpass those of traditional materials. One of the primary advantages of silicone gaskets is their exceptional temperature resistance. They can operate effectively in extreme temperatures, ranging from -100°F to +500°F, making them suitable for high-heat applications in automotive and aerospace sectors. Additionally, silicone gaskets exhibit excellent flexibility and compression set resistance, allowing them to maintain a reliable seal even under fluctuating pressure and stress.

Tips: When selecting silicone gaskets, consider the specific temperature and pressure conditions of your application. This ensures that the gasket will perform optimally, reducing the risk of leaks and failures.

Another significant advantage of silicone gaskets is their chemical resistance. Unlike rubber or cork gaskets, silicone can withstand exposure to a wide range of chemicals, oils, and solvents without degrading. This property makes them ideal for use in food processing, chemical manufacturing, and medical applications, where safety and reliability are paramount. By choosing silicone gaskets, industries can enhance longevity and reduce maintenance costs associated with seal replacements.

Tips: Always verify the compatibility of silicone gaskets with the specific chemicals involved in your application to prevent unforeseen breakdowns.

Silicone gaskets are essential components used across various industries, providing reliable sealing solutions due to their excellent resistance to temperature fluctuations and environmental conditions. When it comes to installation, ensuring a clean and dry surface is crucial. Experts recommend applying a silicone sealant to enhance adhesion, thus preventing leaks and drafts. Regular inspection of the gasket during maintenance routines can prevent minor issues from escalating into costly repairs.

For effective maintenance, keep the silicone gaskets clean to prevent mold accumulation, which can compromise their functionality. A recent cleaning hack involves using a common household product to easily remove mold from silicone sealant. Additionally, for applications such as RV awnings, lubricating moving parts with a dry silicone lubricant facilitates smoother operation and extends the life of the components. It’s vital to address seasonal maintenance, as neglect can lead to more significant system failures and expensive repairs down the line. Regularly caring for these critical seals ensures their performance and longevity across various applications.