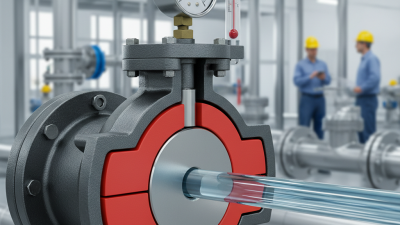

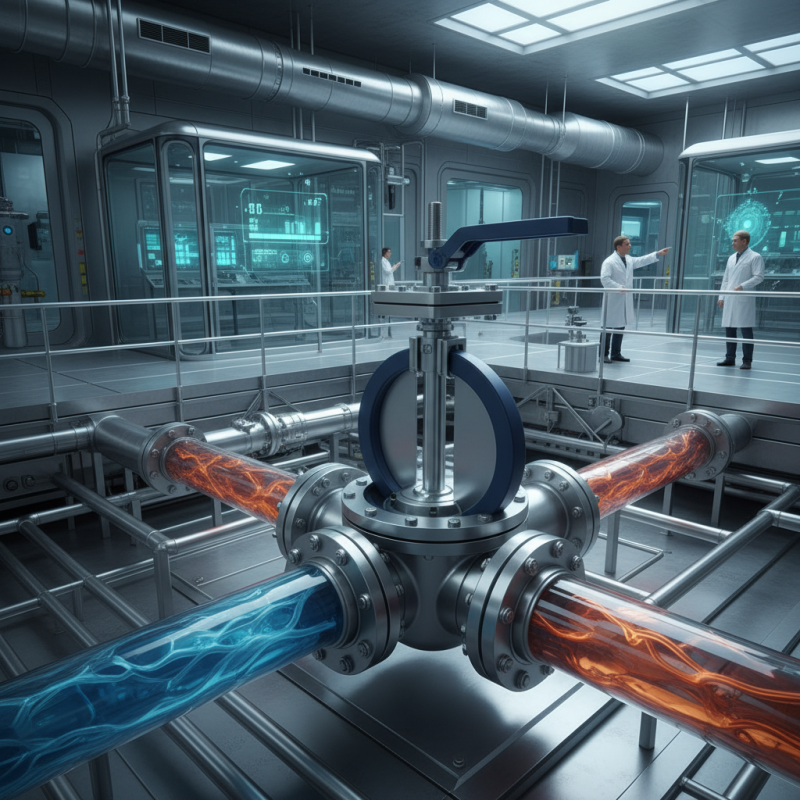

The Resilient Seated Butterfly Valve represents a pivotal advancement in fluid control technology, particularly as we look towards its advantages and applications in the year 2025. Designed for superior performance and durability, this valve type combines a lightweight design with exceptional sealing capabilities, making it ideal for a wide variety of industrial applications. Its unique resilience not only enhances the valve's lifespan but also ensures a reliable operation even under fluctuating pressure and temperature conditions.

As industries increasingly prioritize efficiency and sustainability, the Resilient Seated Butterfly Valve emerges as a key component in achieving these objectives. With applications spanning water treatment, chemical processing, and HVAC systems, its versatility offers significant benefits in improving operational efficiency while reducing maintenance costs. Furthermore, the ongoing advances in manufacturing techniques and materials will likely propel its integration into innovative systems, reinforcing its role in contemporary infrastructures. As we transition into a more technologically advanced era, understanding the benefits and potential applications of the Resilient Seated Butterfly Valve will be essential for engineers and decision-makers alike.

Resilient seated butterfly valves have become increasingly favored in various industrial applications due to their unique advantages. One of the most significant benefits is their ability to provide a reliable sealing solution even in demanding environments. The resilient seat material helps to ensure a tight seal that prevents leakage, which is crucial in processes involving liquids and gases. This characteristic not only enhances system efficiency but also minimizes potential environmental impacts, making these valves a sustainable choice for modern industries.

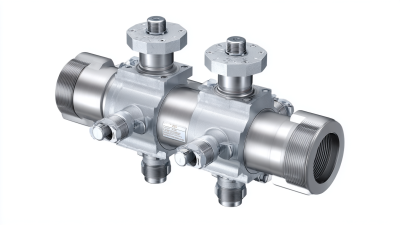

Another notable advantage of resilient seated butterfly valves is their lightweight and compact design, which facilitates easier installation and maintenance. Unlike traditional valves that may require extensive support structures, the streamlined design of these butterfly valves allows for significant space savings within piping systems. Additionally, their simpler mechanism reduces the complexity of operation, resulting in lower maintenance costs and less downtime. As industries continue to evolve towards automation and efficiency, the resilience and adaptability of these valves position them as an ideal solution for a wide range of applications, including water treatment, HVAC systems, and chemical processing.

Resilient seated butterfly valves are gaining recognition for their superior performance metrics in various applications. These valves, designed with a resilient seat, offer significant advantages in fluid flow control due to their lightweight construction and low torque requirements. Their unique design allows for quick opening and closing, making them ideal for systems that demand efficiency and responsiveness. The reduced friction associated with resilient seating further enhances their performance, extending the service life and reducing maintenance needs.

Tips: When selecting resilient seated butterfly valves for your projects, always consider the specific requirements of your fluid system, including pressure, temperature, and flow characteristics. Choosing the right size and type can significantly impact overall efficiency.

In 2025, the application of resilient seated butterfly valves is expected to expand in areas such as water treatment, HVAC systems, and industrial processes. Their ability to handle various media, paired with excellent sealing capabilities, positions them as a preferred choice for both new installations and retrofits. As industries prioritize sustainability and operational efficiency, these valves will play a crucial role in optimizing processes and reducing energy consumption.

Tips: Regular maintenance checks can help in identifying wear and tear early, ensuring that your butterfly valves continue to operate at peak efficiency.

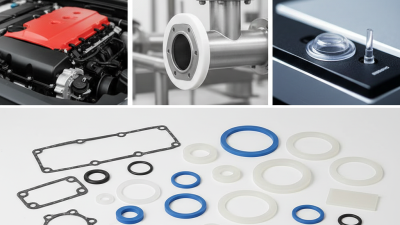

In 2025, the resilience of seated butterfly valves is greatly enhanced by material innovations that significantly improve their durability and resistance. Advancements in composite materials have led to the development of components that withstand extreme pressure and temperature variations, making these valves suitable for a wide range of demanding applications. Modern elastomers and polymers are engineered to resist corrosion, wear, and chemical degradation, thereby extending the lifespan of these vital components in various industries, including water management, oil and gas, and chemical processing.

Additionally, the integration of smart materials in valve construction enhances their performance by allowing for self-healing properties and adaptive responses to environmental changes. This innovation not only contributes to operational efficiency but also reduces the maintenance costs associated with traditional valve systems. As industries focus more on sustainability, these newly developed materials ensure that seated butterfly valves can meet the increasing demands for environmentally friendly solutions without compromising on reliability or performance. The combination of advanced engineering and novel materials positions resilient seated butterfly valves as a leading choice for future infrastructural needs.

| Aspect | Details |

|---|---|

| Material Innovations | Advanced composite materials enhancing resistance to corrosion and wear. |

| Durability | Increased lifespan due to improved sealing technology and robust construction. |

| Temperature Range | Suitable for a wider range of temperatures, from -50°C to 150°C. |

| Applications | Water treatment, chemical processing, oil and gas distribution. |

| Installation | Easy installation and maintenance reducing downtime and costs. |

| Advantages | Lightweight, compact design; low operating torque; and effective sealing. |

The comparative analysis of resilient seated butterfly valves and traditional butterfly valves reveals significant differences in their performance and applicability. Resilient seated butterfly valves, designed with an elastomeric seat, offer improved sealing capability, particularly in applications requiring tight shut-off. This characteristic reduces the risk of leakage, making them ideal for use in water treatment facilities and other applications where fluid control is critical. In contrast, traditional butterfly valves, often made from metallic materials, may not provide the same level of sealing efficiency, particularly as they wear over time.

Another advantage of resilient seated butterfly valves is their versatility in handling a variety of media, including corrosive substances. Their construction allows for better resistance to wear and tear, extending their operational life significantly compared to their traditional counterparts. This durability can translate into lower maintenance costs and less frequent replacements. On the other hand, traditional butterfly valves might excel in high-pressure applications or in environments where extreme temperatures are present, where their robust metal construction can be beneficial. Overall, while both valve types have their respective strengths, the resilient seated butterfly valve stands out in scenarios demanding precise control and reduced leakage risk.

The market for resilient seated butterfly valves is poised for significant growth in 2025, driven by various industrial demands and advancements in valve technology. Increasingly, industries such as water management, wastewater treatment, and HVAC systems are recognizing the benefits of resilient seated butterfly valves, which offer superior sealing capabilities and enhanced durability. As facilities prioritize efficient fluid control solutions, these valves are becoming a preferred choice due to their ability to operate with minimal maintenance and their effectiveness in high-volume applications.

Additionally, the rising focus on sustainability within industrial operations is influencing market trends. Resilient seated butterfly valves are often favored for their energy-efficient designs, which contribute to reduced operational costs. In 2025, the integration of smart technologies and automated systems is expected to further propel the demand for these valves. Their compatibility with modern monitoring and control systems allows for more effective performance tracking and predictive maintenance, ensuring optimal operation and longevity. Overall, the forecast for resilient seated butterfly valves is bright, with continuous innovation driving their adoption across multiple sectors.