Nitrile Rubber is a versatile synthetic material. It is widely used in various industries due to its unique properties. This rubber shows excellent resistance to oils and abrasion, making it ideal for demanding applications.

In automotive settings, Nitrile Rubber is crucial for seals and gaskets. It ensures durability and reliability. This material also finds use in medical gloves, providing safety against contamination. Its flexibility and strength make it indispensable in these areas.

Despite its advantages, Nitrile Rubber has its drawbacks. It can degrade under prolonged UV exposure. Manufacturers must consider these limitations. Understanding both its strengths and weaknesses is essential for optimizing its applications.

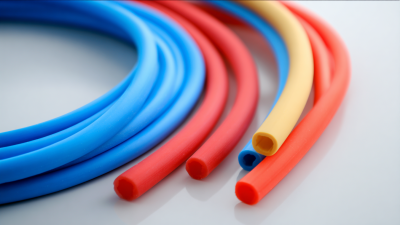

Nitrile rubber, also known as NBR, is a synthetic rubber. It is made from the copolymerization of acrylonitrile and butadiene. This unique combination gives nitrile rubber its key properties. It is often used in automotive seals, hoses, and gaskets.

One significant feature of nitrile rubber is its resistance to oil and fuel. This makes it essential in industries where exposure to various chemicals is common. Its durability is impressive, but it isn’t invincible. Nitrile rubber can degrade over time under extreme environmental conditions. It’s vital to consider how prolonged exposure might affect its performance.

Another aspect to note is its flexibility at low temperatures. Nitrile rubber remains pliable even in cold conditions. Yet, the rubber can lose some of its elasticity over time. Thus, regular checks are needed to ensure functionality. Overall, nitrile rubber plays a crucial role in many applications, but it requires careful handling and monitoring to maintain its effectiveness.

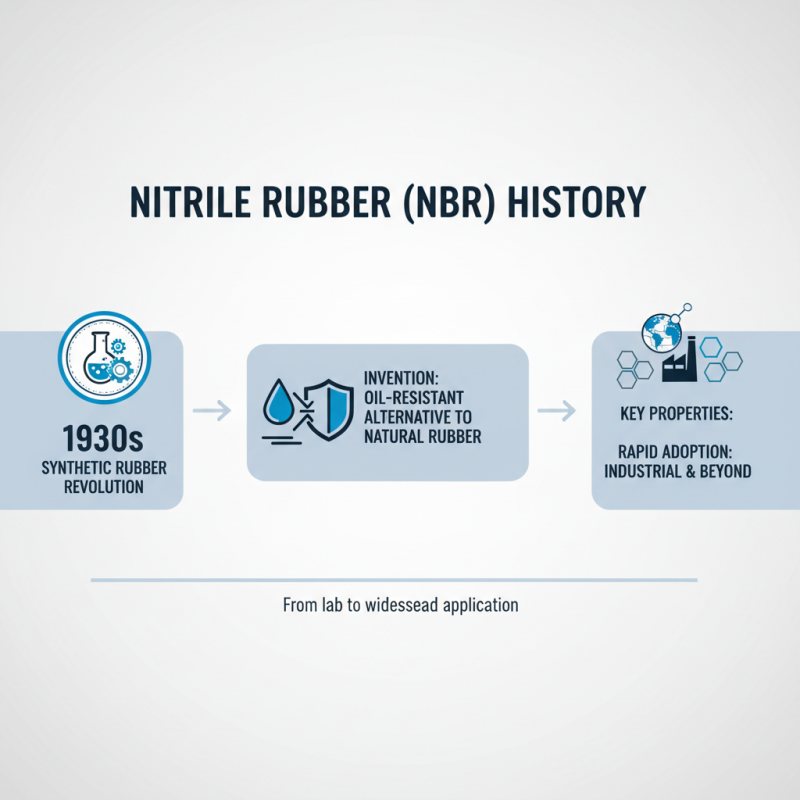

Nitrile rubber, also known as NBR, has a rich history. It was invented in the 1930s during the rubber-synthetic revolution. Researchers needed alternatives to natural rubber, especially for oil-resistant applications. NBR quickly became favorable due to its strength and resistance to chemical degradation.

By the 1940s, nitrile rubber entered the automotive industry. Its resilience made it suitable for fuel hoses and gaskets. In fact, reports show that the global nitrile rubber market was valued at approximately $1.4 billion in 2020. This figure is expected to grow steadily, with projections indicating a compound annual growth rate (CAGR) of about 5% from 2021 to 2028.

Despite its success, challenges remain. Nitrile rubber can degrade over time if exposed to high temperatures. This weakness has initiated research into enhancing its thermal stability. Various studies emphasize the need for new formulations to improve its performance. The quest for improved materials continues, reflecting the necessity for innovation in this crucial field.

Nitrile rubber is a synthetic elastomer known for its impressive properties. It is primarily composed of acrylonitrile and butadiene. This composition gives nitrile rubber excellent resistance to oils and fuels. The flexible nature of the material makes it ideal for various applications. For instance, it is widely used in gloves, seals, and gaskets.

One key characteristic of nitrile rubber is its durability. It withstands high temperatures and harsh chemicals. This durability is vital in industries like automotive and aerospace. However, not all nitrile rubbers are equal. Variations can affect heat and chemical resistance. Testing different grades is important to find the right fit for specific needs.

Nitrile rubber also has good tensile strength. It can stretch and deform without breaking. This elasticity adds to its appeal in manufacturing. Yet, it does have limitations. It can lose flexibility in extreme cold. Understanding these weaknesses helps in choosing the proper applications. Balancing the pros and cons of nitrile rubber is crucial for effective use.

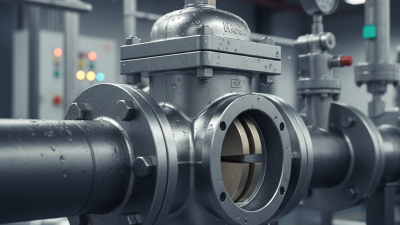

Nitrile rubber, known for its durability and high resistance to oil, has become essential across various industries. In the automotive sector, it is widely used for seals, hoses, and gaskets. Reports suggest that the automotive industry's demand for nitrile rubber will grow by approximately 7% annually through 2025. This growth is driven by the increasing need for fuel-efficient and high-performance vehicles.

In the medical field, nitrile rubber is crucial for manufacturing gloves. These gloves are essential for maintaining hygiene and safety standards. According to industry research, the global nitrile gloves market is projected to reach $7 billion by 2027. However, the supply chain faces challenges, including fluctuating raw material prices. Companies often overlook these risks when projecting growth.

The oil and gas industry uses nitrile rubber for seals and O-rings due to its excellent chemical resistance. With this demand, market studies indicate a shift toward sustainable practices. Yet, many manufacturers struggle to adapt. The need for innovation in recycling nitrile materials remains an area needing attention.

Nitrile rubber is widely used in various industries due to its excellent resistance to oils, fuels, and chemicals. The chart above displays the percentage of usage of nitrile rubber across different sectors, highlighting its significant role in the automotive and aerospace industries.

Nitrile rubber (NBR) is a synthetic rubber known for its remarkable resistance to oils and chemicals. This material plays a crucial role in various industries, including automotive and healthcare. According to a 2022 report by the Global Nitrile Rubber Market, the demand for NBR is expected to grow at a CAGR of 5.1% through 2030, emphasizing its increasing significance in industrial applications.

The importance of nitrile rubber lies in its safety and performance characteristics. It provides excellent protection against hazardous substances, which is vital in medical gloves. These gloves help prevent contamination in healthcare settings. A study from the American Journal of Infection Control noted that nitrile gloves reduce infection rates by up to 30% compared to latex gloves. This statistic underlines the material's critical role in ensuring safety for both patients and healthcare providers.

Furthermore, nitrile rubber is used in automotive seals and gaskets, where durability is crucial. However, not all nitrile materials perform equally under extreme conditions. A noticeable challenge is maintaining flexibility while enhancing chemical resistance. Recent advancements aim to address this issue, but there is still much work to be done. Understanding these properties and potential limitations is essential for improving industrial safety and performance.

| Property | Value | Importance |

|---|---|---|

| Temperature Resistance | -40°C to 120°C | Allows for use in various environments without loss of properties. |

| Oil Resistance | High | Ideal for applications in automotive and industrial sectors. |

| Abrasion Resistance | Excellent | Suitable for high wear and tear applications, enhancing longevity. |

| Chemical Resistance | Moderate to High | Effective against many acids, oils, and fuels. |

| Flexibility | Good | Maintains shape and performance under varying conditions. |

| Applications | Seals, gaskets, hoses, gloves | Wide range of applications ensures safety and performance in critical environments. |