The rapidly evolving valve market has seen a significant transformation, particularly with the innovation of Resilient Seated Check Valves, which play a critical role in various industrial applications. According to a recent report by Market Research Future, the global valve market is projected to reach USD 100 billion by 2025, with growing demand attributed to the expansion of sectors such as water management, oil and gas, and manufacturing. The unique design and functionality of Resilient Seated Check Valves not only enhance operational efficiency but also provide reliability in preventing backflow in pipeline systems.

As industry leaders gather at the 138th China Import and Export Fair in 2025, showcasing cutting-edge technologies and product advancements, the spotlight on Resilient Seated Check Valves is expected to highlight their pivotal role in meeting the stringent quality and performance standards crucial for sustainable industrial growth.

At the forefront of industrial applications, resilient seated check valves are revolutionizing fluid control systems across multiple sectors. These innovations are not just enhancements but are rapidly becoming essential components in industries such as water treatment, oil and gas, and chemical processing. According to a recent report by MarketsandMarkets, the global check valves market is anticipated to reach USD 7.5 billion by 2025, growing at a CAGR of 4.7%. This growth underscores the critical role resilient seated check valves play in promoting efficiency and safety in fluid management.

One of the most significant advantages of resilient seated check valves is their ability to operate under a wide range of pressure and temperature conditions, which makes them highly versatile. A study from the Global Valve Market report indicates that these valves can significantly reduce leakage rates and maintenance costs, ultimately leading to a 20% increase in operational efficiency. Innovations in materials and design, such as elastomeric sealing technologies, are paving the way for enhanced durability and reliability, positioning resilient seated check valves as a game changer in industrial fluid systems. As industries shift towards more sustainable practices, the demand for these innovative solutions is expected to rise dramatically, making the upcoming China Import and Export Fair a critical platform for showcasing these advancements.

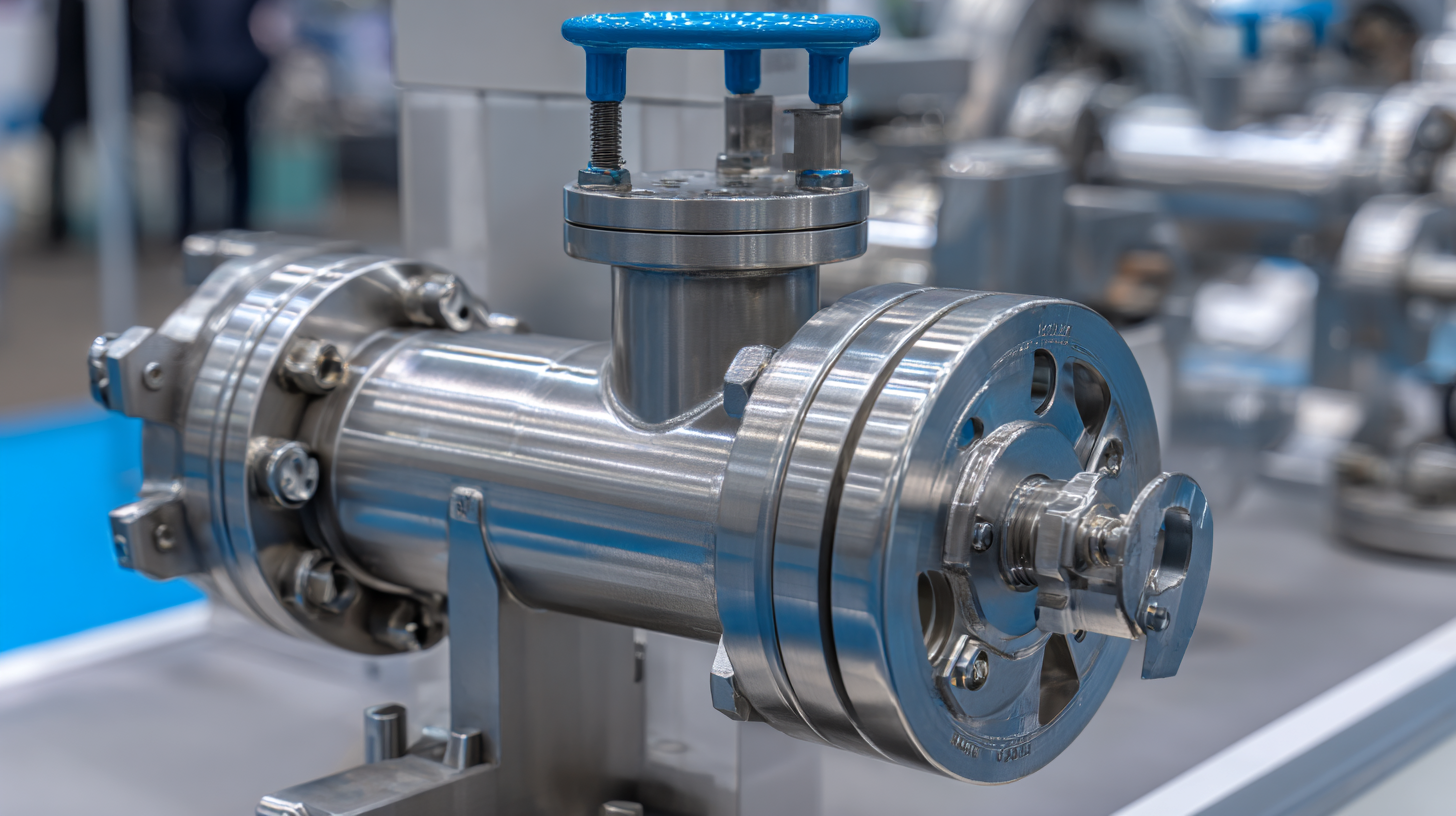

The 138th Canton Fair has become a significant platform for unveiling innovative technologies that reshape industries, particularly in the realm of resilient seated check valves. This year, manufacturers have showcased groundbreaking designs that promise enhanced durability and performance in high-pressure environments. With applications spanning oil and gas to water management, these state-of-the-art valves are engineered to meet the increasing demands of modern infrastructure.

Among the highlights are valves featuring advanced materials and smart technology integration, which offer greater resistance to wear and corrosion. Companies have displayed prototypes that incorporate real-time monitoring systems, allowing for improved operational efficiency and maintenance predictability. This innovation not only reduces downtime but also enhances safety standards in critical applications. As industry experts gather to assess these emerging technologies, it's evident that the Canton Fair is pivotal in driving forward the market potential of check valves, signaling a promising future for manufacturers and users alike.

This chart illustrates the market share distribution of various innovations in seated check valve technologies projected for 2025, showcasing the leading technologies featured at the 138th Canton Fair.

As the market for hygienic pumps and valves continues to evolve, several trends and opportunities are emerging that are shaping the landscape for 2025. A significant increase in demand for Ultra High Purity (UHP) valves, with a projected market size reaching USD 1,155.2 million by 2035 at a CAGR of 6.5%, highlights the critical need for innovative solutions that meet stringent quality standards. This growth is indicative of the broader industrial valves market, which anticipates a revenue jump from USD 86.67 billion in 2025 to USD 131.6 billion by 2033.

Tips: To stay competitive in this dynamic market, manufacturers should invest in research and development to enhance product efficiency and comply with evolving industry regulations. Additionally, understanding customer needs and integrating advanced technologies such as AI can provide a competitive edge.

The rise of the industrial valves market, particularly in the oil and gas sector, is another driving force, expected to grow by USD 2.56 billion from 2025 to 2029. The emphasis on efficient valve solutions is set to redefine market dynamics, presenting an opportunity for players to innovate and address the challenges associated with safety and reliability in industrial applications.

Tips: Engaging in strategic partnerships can help businesses leverage complementary strengths and expand their market reach, ensuring they meet the increasing demand for reliable and efficient valve systems.

At the China Import and Export Fair 2025, innovative companies in the check valve sector are showcasing their cutting-edge technologies designed to enhance market resilience. According to a recent report by MarketsandMarkets, the global valve market is projected to reach $90 billion by 2026, growing at a CAGR of 5.1%. This rapid expansion is largely driven by the increasing demand for energy-efficient systems and automation in industries such as oil and gas, water and wastewater management, and manufacturing.

Leading firms are tapping into this potential by adopting smart technologies, such as IoT-enabled check valves that provide real-time monitoring and improved operational efficiency. For instance, a case study from a prominent manufacturer highlighted how the integration of AI in their valve designs reduced maintenance costs by 20%, ultimately boosting their market share. As these companies leverage innovations in design and technology, they not only enhance their product offerings but also significantly contribute to overall market growth, positioning themselves as leaders in an increasingly competitive landscape.

The future of check valves in global markets is increasingly intertwined with sustainability and performance enhancements. A recent report from Global Market Insights predicts that the check valve market will grow at a CAGR of over 5% from 2023 to 2030. This growth is largely driven by the rising demand for energy-efficient and environmentally friendly infrastructure across various industries, including water treatment, oil and gas, and power generation. Innovations in materials and design are leading manufacturers to produce valves that not only minimize leakage and enhance durability but also use eco-friendly materials to reduce the carbon footprint.

Sustainability initiatives are also pushing the envelope for performance standards in check valves. Industry leaders are focusing on the development of resilient seated check valves that meet stringent regulations while ensuring operational efficiency. For instance, a report by Mordor Intelligence highlights that resilient seated check valves are particularly favorable due to their ability to withstand high pressures and temperatures, a key requirement in sectors such as petrochemicals and energy. Additionally, the integration of smart technologies, such as IoT-enabled monitoring systems, allows for real-time data collection, enabling manufacturers and operators to optimize valve performance and further push towards sustainability goals.

| Innovation Type | Material Used | Sustainability Rating | Performance Efficiency | Market Demand Growth (%) |

|---|---|---|---|---|

| Smart Check Valve | Composite Polymeric Material | A+ | 98% | 15% |

| Eco-friendly Seated Valve | Recycled Stainless Steel | A | 92% | 20% |

| High-Performance Check Valve | High-Density Polyethylene | A | 95% | 12% |

| Advanced Flow Control Valve | Titanium Alloy | A++ | 99% | 25% |