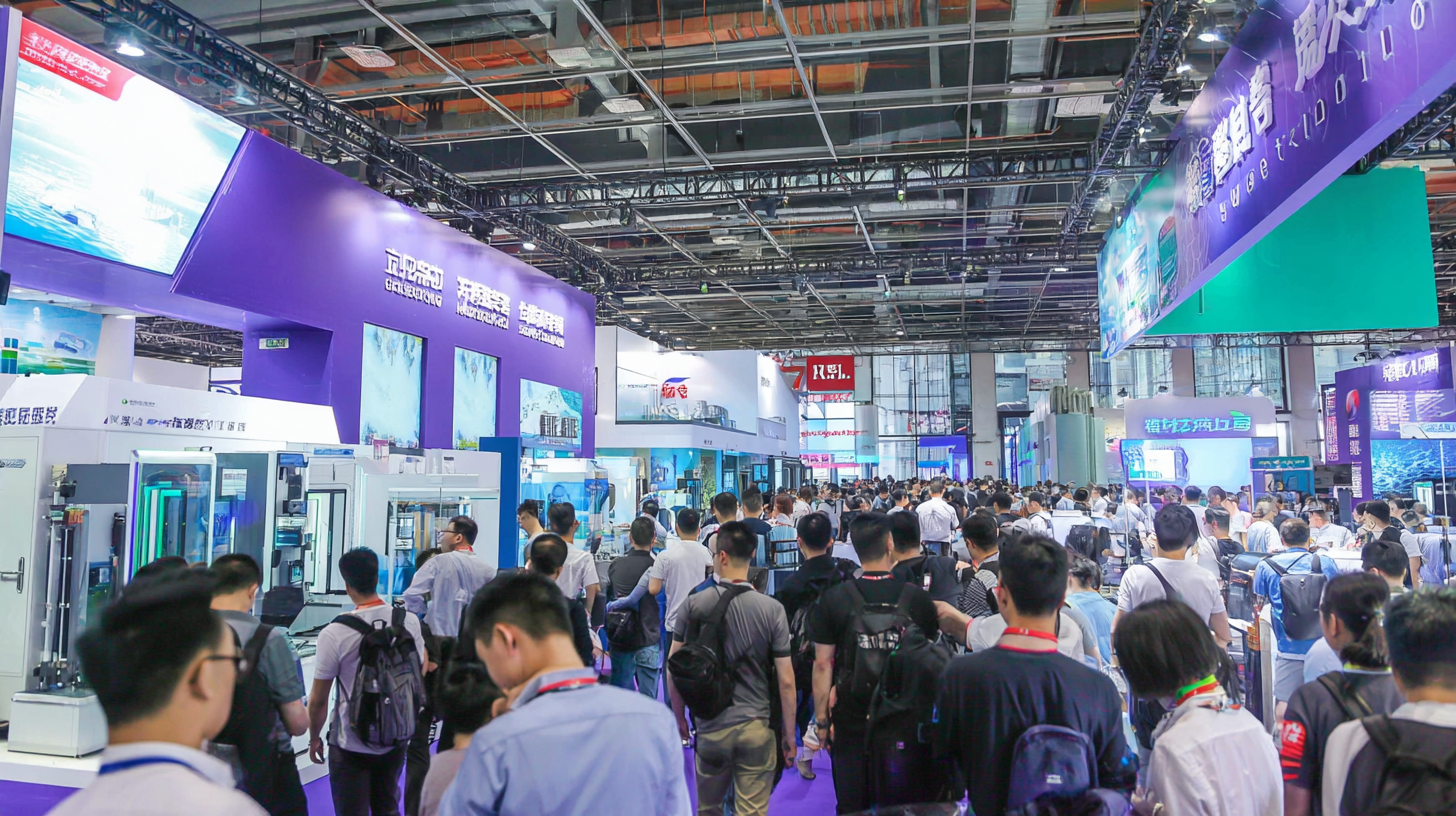

The 138th Canton Fair in 2025 serves as a pivotal platform showcasing the innovative applications of Silicone Rubber, a material that has revolutionized various industries. According to a report by Markets and Markets, the global Silicone Rubber market is projected to reach $29.5 billion by 2026, growing at a CAGR of 6.4% from 2021. This growth is driven by the rising demand for silicone in applications such as automotive, electronics, and healthcare. At the Canton Fair, manufacturers and suppliers will present cutting-edge products that leverage the unique properties of Silicone Rubber, including its thermal stability, flexibility, and resistance to weathering. This event not only highlights the ongoing advancements within the industry but also reflects the increasing importance of sustainable and innovative materials in driving economic growth. The emphasis on Silicone Rubber at this esteemed trade fair underscores its vital role in shaping the future of manufacturing and technology.

The 138th Canton Fair in 2025 will showcase a myriad of innovative uses of silicone rubber, a material rapidly gaining traction in product design across various industries. According to a recent report by Research and Markets, the global silicone rubber market is projected to reach $10.5 billion by 2027, growing at a compound annual growth rate (CAGR) of 4.5%. This growth is attributed to the material's excellent thermal stability, flexibility, and resistance to chemicals and weathering, making it an ideal choice for designers aiming to create durable and aesthetically appealing products.

At the Canton Fair, visitors can expect to see silicone rubber being utilized in not just traditional applications, such as medical devices and automotive components, but also in more creative avenues, including consumer electronics and home décor. The ability of silicone rubber to be molded into complex shapes allows designers to push the boundaries of conventional aesthetics. A study from Allied Market Research highlighted that the use of silicone rubber in consumer goods is anticipated to grow significantly, reflecting a shift toward more sustainable and efficient material options in alignment with contemporary design trends. This opportunity for innovation underscores the transformative potential of silicone rubber in shaping future product designs.

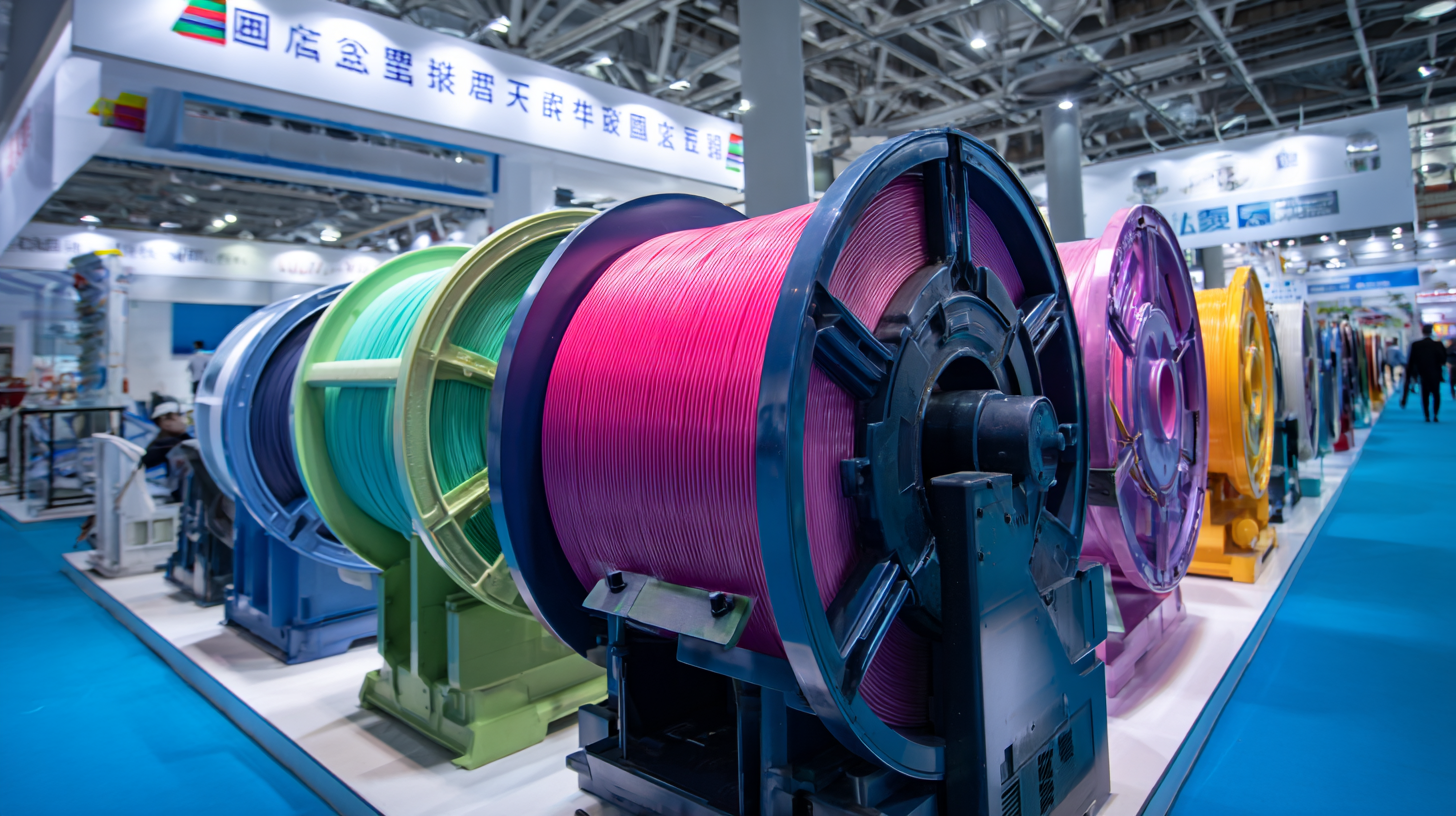

The 138th Canton Fair in 2025 showcased a remarkable shift in the applications of silicone rubber across diverse industries, reflecting substantial growth and innovation. One notable trend is the increasing use of silicone in the automotive sector, where its durability and heat resistance are revolutionizing components such as gaskets and seals. This transition not only enhances performance standards but also supports the industry's push towards sustainability through materials that reduce vehicle weight and improve energy efficiency.

In the consumer electronics arena, silicone rubber is gaining traction in creating protective casings and flexible components for devices. Its inherent resistance to extreme temperatures and its ability to withstand wear and tear make it an ideal choice for manufacturers seeking to enhance product longevity. Additionally, the health and wellness industry is leveraging silicone for its biocompatibility, particularly in medical devices and wearable technology, driving further demand and innovation in this versatile material. As demonstrated at the fair, these trends signify a broadening horizon for silicone rubber applications, setting the stage for future advancements and market expansion.

The showcase of eco-friendly silicone rubber solutions at the 138th Canton Fair in 2025 underscores a significant shift towards sustainable development in the rubber industry. With the rising demand for environmentally friendly silicone products, market assessments predict a robust growth trajectory for silicone rubber and advanced liquid injection molding systems through 2033. This trend aligns with recent reviews that emphasize utilizing sustainable materials, such as nano-reinforced self-healing rubbers made with various eco-friendly nanofillers, which not only enhance performance but also minimize environmental impact.

Moreover, advancements in recycling technologies for silicone waste are paving the way for a circular economy within the materials sector. For instance, innovative methods developed for converting rubber waste into advanced polymer composites reflect the industry's commitment to sustainability. This is bolstered by new findings on the use of agricultural waste in creating polymer-based dielectric composites, highlighting the potential for integrating renewable resources into silicone production. The industry’s collective efforts to embrace sustainable practices promise not only to meet consumer demand but also to catalyze growth while addressing environmental concerns.

This bar chart illustrates the growth of different eco-friendly silicone rubber applications showcased at the Canton Fair, emphasizing sustainable development trends in the industry.

The 138th Canton Fair in 2025 showcased a plethora of innovative applications for silicone rubber, with a particular emphasis on emerging technologies that enhance product performance. Advances in materials science have led to the development of silicone rubber composites that boast improved thermal stability and flexibility, making them suitable for a wider range of industrial applications. These innovations not only increase the durability of the products but also contribute to energy efficiency, appealing to manufacturers seeking to reduce costs while improving product lifespan.

Additionally, breakthroughs in manufacturing techniques, such as 3D printing and injection molding, have revolutionized how silicone rubber products are produced. These technologies allow for intricate designs and reduced waste, promoting sustainability in the production process. As industries increasingly prioritize eco-friendly materials, the incorporation of bio-based silicone rubber solutions reflects a growing trend towards greener manufacturing practices. This confluence of technology and sustainability is positioning silicone rubber as a vital material in various sectors, from automotive to healthcare, ensuring its relevance in future applications.

At the 138th Canton Fair in 2025, silicone rubber manufacturers are set to explore unparalleled networking opportunities, crucial for fostering industry growth. The global silicone rubber market is projected to reach $12.5 billion by 2026, showing a compound annual growth rate (CAGR) of 5.8% from 2021. By participating in the fair, manufacturers can leverage this growth through partnerships, collaborations, and accessing new markets. The engagement with industry leaders and innovators at this event will undoubtedly serve as a catalyst for enhancing production techniques and expanding application areas.

Furthermore, attendees can gain valuable market insights that will inform their strategic decisions. Recent reports indicate that the automotive and healthcare sectors are among the fastest-growing segments for silicone rubber, driven by increased demand for lightweight materials and biomedical applications. By networking with key players in these sectors at the Canton Fair, manufacturers can tap into emerging trends and align their offerings with market needs. The knowledge-sharing environment will not only inspire innovation but also provide essential data to navigate the evolving landscape of silicone rubber applications.