The 138th Canton Fair in 2025 presents a unique opportunity to delve into the latest advancements in rubber wheel manufacturing, a sector that has seen significant growth and innovation in recent years. According to the Rubber Manufacturers Association, the global rubber market is projected to reach approximately $235 billion by 2025, with a substantial portion attributed to the demand for high-performance rubber wheels across various industries including automotive, logistics, and recreational vehicles. Innovations in materials and manufacturing processes are rapidly transforming the rubber wheel landscape, emphasizing enhancements in durability, weight reduction, and cost efficiency. As manufacturers showcase their cutting-edge technologies and designs at the fair, industry stakeholders will have the chance to engage with these innovations directly, paving the way for future collaboration and development in this dynamic market.

At the 138th Canton Fair, innovative rubber wheel designs took center stage, showcasing advancements that are reshaping the industry. With the global rubber wheel market projected to reach $24 billion by 2025, manufacturers are keenly focusing on enhancing performance and sustainability. The introduction of eco-friendly materials and smart wheel technologies is leading the shift towards more efficient and environmentally responsible manufacturing processes.

Among the innovations presented, lightweight designs feature prominently, offering improved maneuverability and reduced energy consumption. According to a recent industry report, the demand for lightweight wheels is expected to grow by over 15% annually as businesses seek to lower operational costs while maximizing efficiency. Moreover, rubber wheels designed with advanced tread patterns are optimized for various terrains, providing users with better grip and durability. This evolution in design not only enhances user experience but also addresses safety concerns in logistics and transportation sectors.

The fair has also seen the advent of customizable rubber wheel solutions, allowing businesses to tailor products to their specific needs. Adaptable rubber formulations and flexible design options empower manufacturers to create wheels that meet niche market demands, emphasizing the critical role of innovation in driving competitive advantages. As the industry continues to evolve, the showcased innovations signal a promising future for rubber wheel manufacturing.

| Dimension | Material Used | Innovation Type | Application Area | Performance Improvement |

|---|---|---|---|---|

| Diameter: 50 cm | Synthetic Rubber Compound | Eco-friendly Design | Industrial Trucks | 30% Weight Reduction |

| Diameter: 40 cm | Natural Rubber | Noise Reduction Technology | Transportation Vehicles | Decreased Noise by 25dB |

| Diameter: 60 cm | Recycled Rubber | Enhanced Grip | Agricultural Equipment | Improved Traction by 40% |

| Diameter: 70 cm | Polyurethane Blend | Weight Optimization | Warehouse Handling | Increased Load Capacity by 500 kg |

| Diameter: 80 cm | Special Composite Material | Thermal Resistance | Heavy Machinery | Operational Temperature Range Improved by 100°C |

The 138th Canton Fair 2025 serves as a pivotal platform for exploring innovative developments in rubber wheel manufacturing, particularly focusing on sustainable manufacturing practices. As the global demand for eco-friendly products rises, the rubber industry is responding by adopting greener technologies. According to a recent market report by Allied Market Research, the sustainable rubber market is projected to reach $50 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.5%. This growth is driven by the implementation of recycling processes and renewable raw materials, which contribute significantly to reducing the carbon footprint associated with rubber wheel production.

Incorporating sustainable practices not only aligns with environmental regulations but also meets consumer expectations for eco-conscious products. Leading manufacturers are investing in biodegradable materials and energy-efficient production methods. A survey by the International Rubber Study Group highlights that 70% of rubber producers worldwide are prioritizing sustainability in their operations. Initiatives such as utilizing factory waste in production and adopting closed-loop systems are increasingly seen as viable strategies to enhance sustainability. As businesses present their innovations at the Canton Fair, the focus will likely be on collaborative efforts to promote environmentally responsible practices and shared learning across the industry.

At the 138th Canton Fair 2025, the rubber wheel manufacturing sector is witnessing groundbreaking technological advancements that are reshaping the industry. A recent report from MarketsandMarkets indicates that the global rubber market is projected to reach USD 488.2 billion by 2026, driven by innovations in manufacturing processes and materials. At the fair, exhibitors are showcasing state-of-the-art developments such as automated production lines and the integration of artificial intelligence in quality control, which streamline operations and enhance product consistency.

Moreover, sustainable manufacturing practices are gaining momentum, with companies increasingly adopting eco-friendly materials and energy-efficient technologies. According to a study by Technavio, the demand for sustainable rubber products is expected to grow at a compound annual growth rate (CAGR) of 5.6% from 2023 to 2027. This trend is evident at the Canton Fair, where manufacturers are not only focusing on performance but also on the environmental impact of their products. With these innovations, the rubber wheel industry is poised for significant growth and transformation in the coming years, reflecting a commitment to both quality and sustainability.

The recent advancements in rubber wheel applications across various industries highlight a trend toward increased durability and performance. Innovations in lightweight composite materials have transformed manufacturing processes, enabling the creation of more efficient and resilient rubber wheels. This shift not only enhances the overall functionality of products but also contributes to sustainability goals as manufacturers seek to reduce material usage without compromising quality.

Moreover, the automotive sector is witnessing a growing demand for specialized rubber wheels, particularly in the context of electric and heavy-duty vehicles. Companies are adapting to evolving market needs by developing tailored solutions that cater to the specific performance requirements of different applications, including those in commercial fleets. As the global rubber compound market is projected to grow significantly, the emphasis on advanced technologies and materials in rubber wheel manufacturing will likely play a pivotal role in shaping future trends across multiple industries.

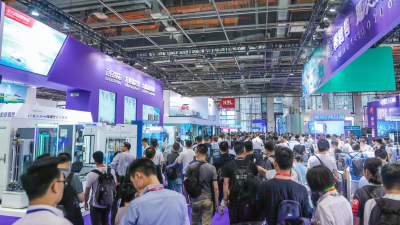

The 138th Canton Fair in 2025 presents a unique platform for rubber wheel manufacturers to network and explore innovative solutions within the industry. With manufacturers and suppliers from around the globe attending, the fair fosters an environment rich with opportunities to establish valuable connections. Networking can lead to collaborations that drive product innovation, enhance quality, and reduce costs in rubber wheel manufacturing. Attendees can engage in discussions, share insights, and discover potential partnerships that can significantly impact their business strategies.

Tips for effective networking at the Canton Fair include arriving prepared with business cards and a clear idea of your objectives. Actively participate in seminars and workshops focusing on industry trends, as they attract key players and create a space for genuine dialogues. Engaging in casual conversations in shared spaces such as food courts or lounges can also lead to fruitful connections. Establishing rapport through these informal interactions often opens doors to deeper discussions regarding collaboration and innovation in the rubber wheel sector.