Vulcanized rubber is a critical material in various industries. According to a recent report by MarketsandMarkets, the global vulcanized rubber market was valued at over $30 billion in 2022, with an expected growth rate of 5.9% annually. This growth reflects its crucial role in automotive, aerospace, and consumer goods applications.

Expert Dr. Emily Martinez, a leading authority in polymer science, emphasizes, "Understanding the nuances of vulcanized rubber can significantly enhance product longevity and performance." This insight is vital for industry professionals aiming to optimize their processes. Effective handling and processing of vulcanized rubber can prevent common issues like brittleness and degradation.

Despite its advantages, many still overlook the essential tips for working with vulcanized rubber. Poor practices can lead to increased waste and reduced efficiency. Landscaping techniques and proper storage conditions can preserve the material's integrity. By reflecting on these considerations, industry stakeholders can improve their outcomes and maintain high standards in their operations.

Vulcanized rubber is a versatile material prized for its durability and elasticity. The process of vulcanization involves heating rubber with sulfur, which creates cross-links between polymer chains. This chemical reaction strengthens the rubber, making it more resistant to wear and temperature changes. As a result, vulcanized rubber is used in various applications, from tires to seals, thanks to its robust nature.

Understanding its properties is essential for effective use. Vulcanized rubber can withstand harsh conditions, but it is not indestructible. It can degrade with exposure to ozone, UV light, and certain chemicals. Therefore, regular inspections are vital. Small cracks or discolorations may indicate wear and tear. Proper storage away from sunlight can prolong its life.

Working with vulcanized rubber requires attention to detail. Cutting and shaping it can be challenging, as it may not behave as one might expect. Sometimes tools slip, causing uneven edges. Practicing techniques on scrap pieces can help. It’s crucial to learn from mistakes, as each error offers insight into better handling practices.

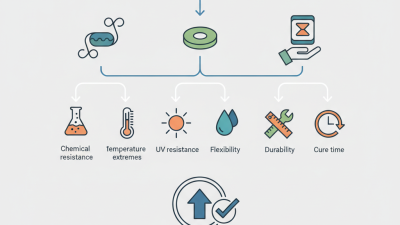

This chart illustrates the various properties of vulcanized rubber, highlighting its key characteristics that affect its usage in various applications.

When working with vulcanized rubber, selecting the right tools is pivotal. Specialized knives and blades help achieve clean cuts. According to a recent report from the Rubber Manufacturers Association, precise tools can reduce material waste by up to 15%. This efficiency saves both time and resources, crucial for any project.

Using adequate pressure while cutting is vital. Improper force can lead to jagged edges. Aim for a steady application of pressure to avoid this common mistake. Hand tools like shears may require various techniques, which can complicate the process. Many inexperienced users struggle with achieving consistency, often leading to frustration and subpar results.

In addition to cutting tools, consider your workspace. A clean, organized area promotes safety and productivity. Reports indicate that cluttered environments can reduce efficiency by as much as 30%. Pay attention to alignment when laying out pieces. Sometimes, misalignment stems from a rushed setup, which can compromise the overall quality of your work. Careful preparation fosters better outcomes in the long run.

Cutting and shaping vulcanized rubber can be tricky. It's not as straightforward as it seems. Start with a sharp knife or utility blade. Dull tools can lead to uneven edges. Make sure to work on a sturdy surface. A cutting mat can protect your blade and your workspace.

When shaping rubber, heat can be beneficial. Use a heat gun to soften the material. This makes it easier to manipulate. However, too much heat can cause damage or melting. Be cautious and keep the heat source moving. Measure twice and cut once. It's a common saying, but it really helps avoid mistakes.

Not all cuts will be perfect. There may be frayed edges or awkward angles. Embrace these imperfections; they add character. You can always sand or trim rough edges later. Keep practicing your technique. Each attempt brings improvement. It can be a frustrating process, but persistence pays off.

When working with vulcanized rubber, selecting the right adhesives is critical. Studies show that adhesion strength can vary significantly based on the adhesive used. For instance, rubber-to-metal bonding typically requires specific materials to achieve a lasting bond. A report by the Rubber Manufacturers Association highlights that effective adhesion methods can enhance durability by over 30%.

Understanding the bonding methods available is essential. The most common methods are pressure-sensitive adhesives, solvent-based adhesives, and polyurethane. Each method has its limitations and strengths. For example, pressure-sensitive adhesives may not withstand extreme temperatures. Meanwhile, polyurethane can offer better temperature resistance, but the bonding process might be more complex.

Many industries struggle with inconsistent results during bond creation. Improper surface preparation often leads to weak bonds. Cleaning and priming the rubber surface can significantly impact adhesion quality. Industry data suggests that surface treatments can improve bonding effectiveness by up to 40%. A meticulous approach to surface preparation and adhesive selection can foster better outcomes and reduce the likelihood of failures in rubber applications.

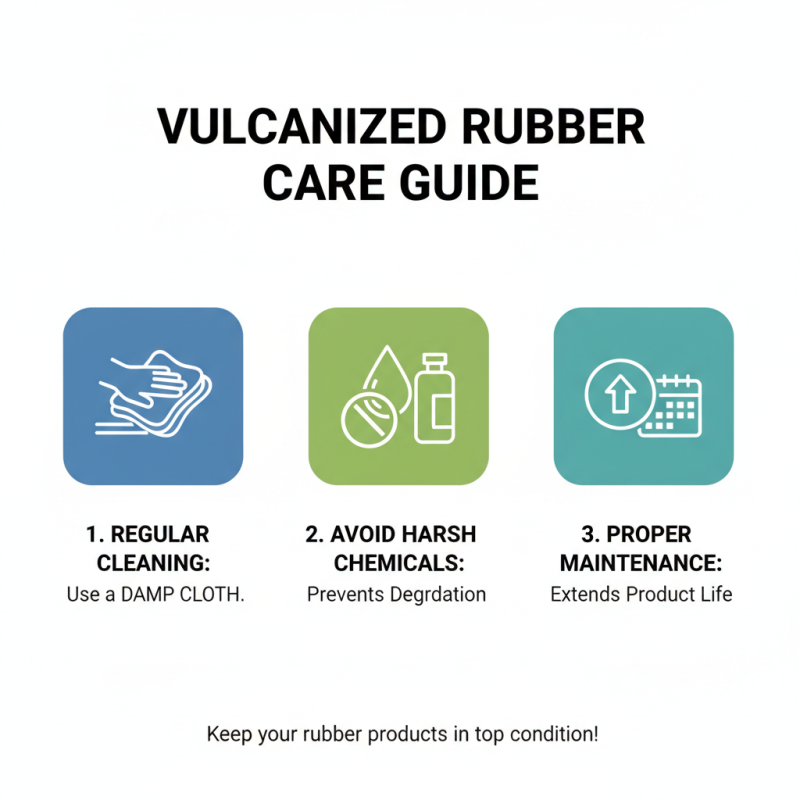

Vulcanized rubber is used in various projects, but maintenance is crucial. Proper care can extend the life of your rubber products. Regular cleaning is essential. Use a damp cloth to remove dirt and grime. Avoid harsh chemicals. They can degrade the rubber surface over time.

Inspect the rubber periodically for cracks or wear. Early detection can prevent bigger issues later. Store vulcanized rubber in a cool, dry place. High temperatures can lead to deformation. Keeping it away from direct sunlight also helps.

Consider how you handle the material. Excessive bending can weaken the rubber structure. Some may overlook this detail. As a result, they may face unexpected failures later on. Maintaining vulcanized rubber requires attention and diligence. Reflect on your practices frequently.