When embarking on a new project, choosing the right materials is crucial. Among them, the **Silicone Rubber Sheet** stands out for its versatility and durability. This material is used in a wide range of applications, from crafting to industrial use. Its flexible nature allows for creative designs and functional solutions.

However, using **Silicone Rubber Sheets** can be challenging for beginners. Not every project will require the same thickness or type of sheet. Understanding these differences is vital to achieving desired results. Furthermore, not sticking to best practices can lead to frustrating outcomes. Mistakes like improper cutting or lack of proper adhesion are common pitfalls.

In this article, we will explore ten essential tips for effectively using **Silicone Rubber Sheets** in your projects. Each tip aims to enhance your experience and help you make informed choices. For instance, selecting the wrong adhesive can ruin your hard work. Learning from these tips may prevent mishaps and improve overall project quality.

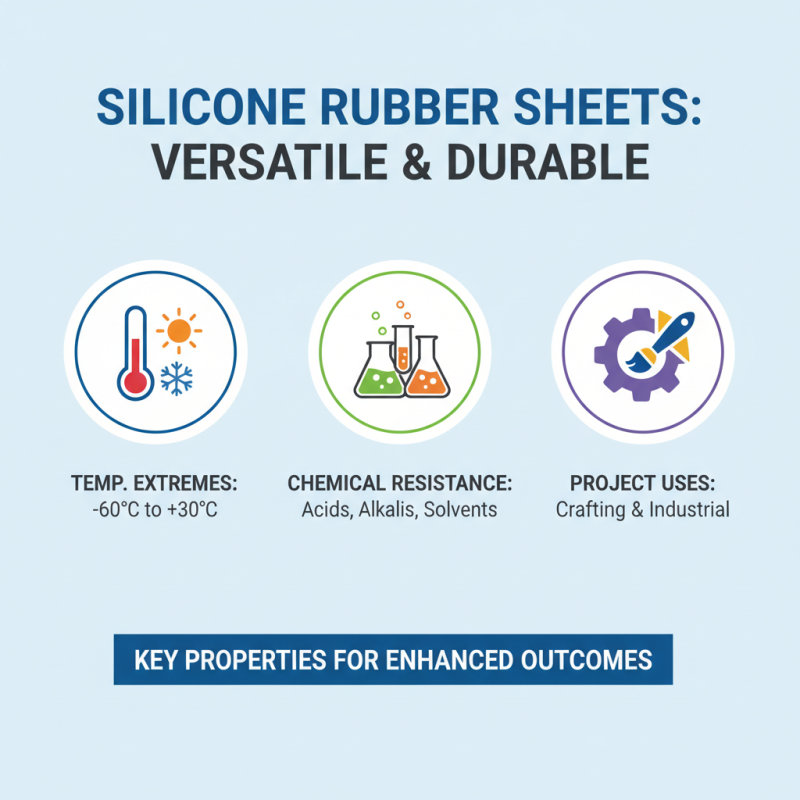

Silicone rubber sheets are known for their versatility and durability. They offer excellent resistance to temperature extremes and chemicals. This makes them ideal for various projects, from crafting to industrial use. Understanding their properties can enhance your project outcomes significantly.

When working with silicone rubber sheets, consider these tips. Ensure you cut the sheets accurately. A straight edge and a sharp knife can help prevent jagged edges. Use a dedicated cutting mat underneath to protect your surfaces. While these sheets are durable, they can be challenging to bond. Experiment with different adhesives to find what works best for your needs. Sometimes, a trial and error approach is necessary.

Another key aspect is thickness. Choose a thickness that suits your project. Thicker sheets provide more support, while thinner sheets offer flexibility. Keep in mind that the flexibility can vary between different types of silicone rubber. So, be prepared to test multiple options before finalizing your choice. Also, consider adding texture. Textured sheets can enhance grip or aesthetic appeal, leading to a more polished final product.

Choosing the right thickness and durometer for silicone rubber sheets can significantly impact your project's performance. Thickness determines the sheet's strength and flexibility. For heavy-duty applications, a thicker sheet is often necessary. Reports suggest that a thickness of 1/8 inch is common in many industrial uses. Meanwhile, thinner sheets, around 1/16 inch, are better suited for more delicate tasks. It's crucial to assess your project's requirements carefully before deciding.

Durometer measures hardness, mentioned in Shore A scale. A softer durometer, like 30A, allows for more flexibility. This is suitable for gaskets or seals. On the other hand, a harder durometer, such as 70A, offers greater stiffness and resistance to wear. In industry reports, it's noted that 50A to 60A is a balanced choice for many applications. However, balancing flexibility and strength isn’t always straightforward. Over the years, improper durometer choices have led to product failures in various projects, reminding us to rethink our selections. Understanding these factors will help you make informed choices that lead to successful outcomes.

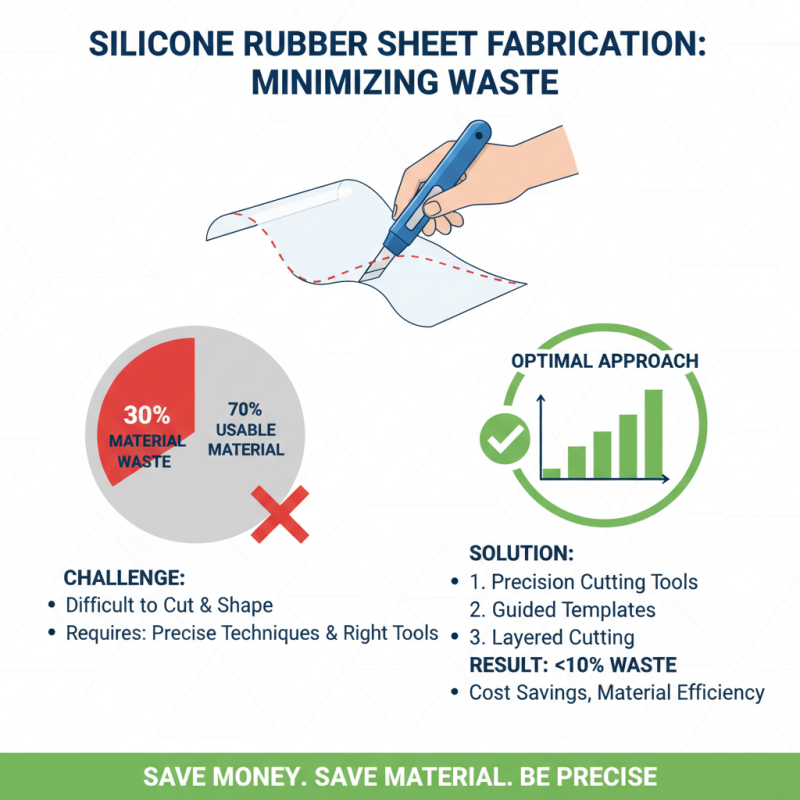

Cutting and shaping silicone rubber sheets can be challenging. It requires precise techniques and the right tools. According to industry reports, improper cutting methods can waste up to 30% of material. This waste is costly, especially in large projects. Having the right approach is essential to minimize this loss.

When cutting silicone rubber sheets, use a sharp utility knife for clean cuts. This helps maintain the integrity of the material. Smooth edges are crucial for components that need to fit tightly. Another technique involves using a straightedge as a guide. It aids in achieving even, straight lines. This might be overlooked, but it’s vital for better accuracy.

Shaping the silicone sheet is equally important. Heat can make this process easier. A heat gun softens the material, allowing it to bend without cracking. However, overheating can lead to deformities. You might find the fine line between pliability and damage hard to gauge. Experimentation is key. Understanding the properties of silicone is an ongoing learning curve for many. Keep track of your processes and results to refine your technique.

Silicone rubber sheets are widely used in various projects. Understanding adhesives is crucial for effective bonding. Not all adhesives work well with silicone materials. For instance, traditional glue may not adhere properly, leading to premature failure.

Research from industry experts shows that silicone-specific adhesives are necessary for optimal results. These adhesives maintain flexibility and withstand temperature extremes. They provide a strong bond, crucial for applications like gasket sealing or crafting prototypes. Epoxy and polyurethane adhesives can also be suitable but require proper surface preparation.

Surface preparation is often overlooked. Alcohol wipes or sandpaper can enhance adhesion quality. However, cleaning is not a one-size-fits-all solution. Inadequate cleaning might result in peeling or lifting over time. A complete understanding of your specific project needs is essential to avoid common pitfalls.

Maintaining silicone rubber sheets can significantly extend their lifetime. Proper care ensures they remain effective and durable. Here are some vital tips.

Keep your silicone rubber sheets clean. Use mild soap and water for routine cleaning. Avoid harsh chemicals that might degrade the material. Sometimes, dirt can stick stubbornly. When this happens, gentle scrubbing with a soft brush may help. Regular cleaning reduces wear and tear.

Store the sheets in a cool, dry place. Excessive heat or moisture can lead to deterioration. Rolling is preferable to folding; it prevents creasing and maintains flexibility. It's tempting to stack them carelessly, but that can lead to irreversible damage. Additionally, periodically inspect the sheets for cracks or signs of wear. Early detection prevents bigger issues later.

When using them, avoid sharp objects that can puncture. Silicone rubber is resilient, yet it is not indestructible. Over time, exposure to UV light may affect its integrity. Sometimes, even minor exposure can lead to fading or brittleness. Being mindful of the environment you use these sheets in is key to prolonging their life.