When it comes to selecting the right silicone gasket for your projects, understanding the nuances of material properties and application requirements is crucial. As industry expert Dr. Susan Reynolds, a leading specialist in sealing technologies, once stated, "Choosing the right silicone gasket can significantly impact both performance and longevity of your assemblies." This highlights the importance of making an informed decision, as the wrong choice can lead to leaks and increased maintenance costs.

In today's guide, we will provide you with ten essential tips to navigate the complexities of selecting a silicone gasket tailored to your specific needs. The vast array of silicone materials and designs may seem overwhelming, but with the right approach, you can simplify the selection process and ensure optimal sealing solutions for your application. From understanding the different types of silicone gaskets available to considering environmental factors, our tips aim to empower you to make choices that enhance the reliability and efficiency of your systems. Let's explore how to effectively choose a silicone gasket that meets your requirements and avoids pitfalls that could compromise your project's success.

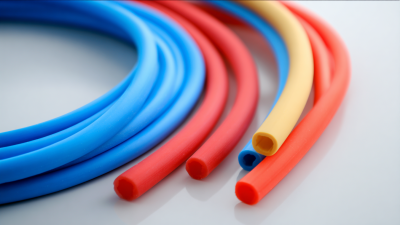

When selecting the right silicone gasket, understanding the various types and their applications is crucial. Silicone gaskets come in a range of formulations and thicknesses, each engineered for specific environments. For instance, high-temperature silicone gaskets are ideal for automotive applications where temperatures can exceed 400°F, according to a recent market analysis by Grand View Research. These gaskets maintain their shape and compressibility even under extreme thermal stress, making them essential for engine components.

Additionally, silicone gaskets can be classified based on their resistance to chemicals, UV exposure, and environmental factors. Medical-grade silicone gaskets, for instance, offer excellent biocompatibility and are utilized in pharmaceutical and food processing industries. Reports from the Silicone Engineering Association indicate that the demand for such specialized gaskets has increased by 15% over the past five years, driven by stricter regulations and a growing focus on safety. Understanding these distinctions can significantly enhance the longevity and performance of your applications, ensuring that you choose the best gasket for your specific needs.

When selecting the right silicone gasket, understanding key properties such as temperature resistance, flexibility, and durability is essential. Silicone gaskets can withstand a broad temperature range, which makes them ideal for applications in automotive, aerospace, and industrial sectors. The silicone market is projected to reach a value of $33.25 billion by 2030, reflecting a compound annual growth rate (CAGR) of 5.2%. This growth is largely driven by their resilience under extreme conditions, which often outperforms traditional materials.

Moreover, flexibility is another critical feature that enhances the performance of silicone gaskets. Their ability to maintain integrity under dynamic loads and varying environmental conditions helps prevent leaks and ensure effective sealing. The global market for liquid silicone rubber, a key component in producing high-quality gaskets, is anticipated to grow at a CAGR of 9.2%, highlighting the ongoing innovation and demand within this sector. As industries increasingly turn to silicone solutions, understanding these essential properties can guide businesses in making informed decisions that optimize their operational efficiency.

When selecting a silicone gasket, evaluating its chemical compatibility with your specific industry standards is crucial for ensuring optimal performance and longevity. According to a report by the Globally Harmonized System (GHS) of Classification and Labeling of Chemicals, varying industrial applications can expose gaskets to a wide range of chemicals, from acids and alkalis to solvents and oils. For instance, the automotive industry, which utilizes silicone gaskets extensively, often samples materials to test resistance against hydraulic fluids and engine oils, where even minor incompatibility can lead to product failure and costly repairs.

Furthermore, data from the American Society for Testing and Materials (ASTM) indicates that silicone compounds show varying resistance levels depending on their formulation and curing process. For industries such as food processing or pharmaceuticals, compliance with FDA regulations adds another layer of complexity, as gaskets must not only withstand harsh chemicals but also be safe for direct contact with foodstuffs. Thus, a complete chemical compatibility assessment, considering both standard industrial practices and regulatory requirements, can save businesses significant time and resources by preventing gasket failures related to chemical interactions.

When it comes to selecting the right silicone gasket, ensuring proper sizing and customization is crucial for achieving optimal sealing performance. One of the first steps is to measure the dimensions of the area where the gasket will be installed. Accurate measurements will help you avoid leaks and inefficiencies, ensuring that your gasket fits snugly in place.

Additionally, consider the material properties of the silicone gasket. Different applications, such as automotive or industrial environments, may require specific heat, chemical, or oil resistance. Choosing a gasket that meets these requirements while also accommodating the size and shape of your installation will greatly enhance its effectiveness.

Moreover, customization options are often available, allowing you to tailor the gasket to your specific needs. Look for manufacturers that provide the ability to adjust thickness, profile, or even the color of the gasket to suit your aesthetic preferences. This level of personalization not only improves functionality but also helps maintain the integrity of your project. Selecting the right silicone gasket means finding a perfect match for both performance and fit.

When selecting the right silicone gasket, balancing cost-effectiveness with quality is crucial. According to a recent market analysis by Grand View Research, the global silicone gasket market is projected to reach $3.6 billion by 2025, growing at a CAGR of 5.5%. This indicates a healthy demand for high-quality silicone gaskets, where customers are increasingly willing to invest in products that guarantee durability and performance. While cheaper alternatives may seem attractive at first glance, they often lead to higher long-term costs due to frequent replacements and potential failures in your systems.

Additionally, industry reports emphasize that performance metrics, such as temperature resistance and chemical compatibility, should not be compromised for a lower purchase price. For instance, a study published in the Journal of Materials Science found that high-quality silicone gaskets exhibit a lifespan that is up to 40% longer than their lower-cost counterparts under extreme conditions. Consequently, while evaluating silicone gaskets, consider not just the initial price, but also the long-term value they provide in terms of reliability and maintenance costs. This approach ensures you make a wise investment that supports your operational efficiency.