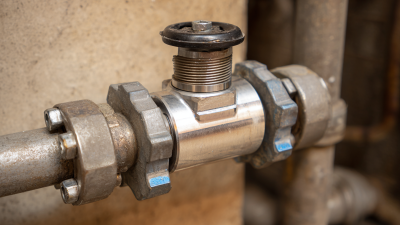

In the ever-evolving landscape of industrial operations, maximizing efficiency while ensuring reliability is paramount. One key component that plays a vital role in achieving this balance is the Resilient Seated Valve. These valves are specifically designed to provide superior sealing performance and durability, making them indispensable in various applications across industries such as water treatment, oil and gas, and manufacturing.

This comprehensive guide will delve into the mechanics of resilient seated valves, exploring their unique features, benefits, and best practices for integration within existing systems. By understanding the critical elements of these valves, businesses can enhance operational productivity, reduce maintenance costs, and ultimately foster a more resilient industrial environment.

Join us as we explore the transformative power of resilient seated valves and how they can significantly improve overall industrial efficiency.

Resilient seated valves play a crucial role in modern industrial applications, offering enhanced performance and efficiency across various sectors. These valves are designed to provide tight sealing and exceptional durability, making them ideal for use in environments where the control of fluid flow is paramount. Their ability to adapt to fluctuating temperatures and pressures ensures the reliability of operations, reducing the risk of leaks and costly downtimes. This adaptability is particularly important in industries such as oil and gas, water treatment, and manufacturing, where precision and resilience are vital.

With over 150 years of expertise in the field, manufacturers of resilient seated valves continuously innovate to meet the evolving demands of the industry. Advances in materials and design have led to valves that not only withstand harsh conditions but also improve overall system efficiency. By incorporating these valves into their processes, industries can achieve significant improvements in energy use and operational effectiveness, ultimately driving productivity and profitability. As the demand for sustainable and efficient solutions grows, resilient seated valves will undoubtedly remain a key component in the pursuit of industrial excellence.

Resilient seated valves are gaining traction in industrial applications due to their superior efficiency and reliability. These valves are designed to maintain a tight seal, reducing the risk of leaks and minimizing the energy loss associated with fluid flow. By effectively managing pressure and flow rates, resilient seated valves contribute to optimal operational efficiency, making them essential components in modern industrial systems. Their lightweight construction and ease of installation further enhance their appeal, allowing for quicker maintenance and reduced downtime.

Tips for Choosing Resilient Seated Valves: When selecting the right resilient seated valve, consider factors such as pressure ratings, temperature ranges, and compatible materials. It's crucial to match the valve specifications to your system's requirements to ensure optimal performance. Additionally, always evaluate the valve's lifecycle costs, including maintenance and replacement, to make a more informed investment.

Incorporating resilient seated valves into your operations not only boosts efficiency but also enhances safety. These valves are less prone to damage from wear and tear compared to traditional alternatives, offering long-term reliability. Regularly inspecting and maintaining these valves is essential to uphold their performance, ensuring a smooth, efficient operation that supports your industrial goals.

Resilient seated valves have emerged as a competitive alternative to traditional valve types, particularly in industrial applications where efficiency and reliability are paramount. Unlike traditional metal seated valves that often suffer from wear and tear, resilient seated valves employ a softer sealing material that enhances the valve's ability to maintain a tight seal even under varying pressure and temperature conditions. This characteristic greatly reduces the risk of leakage, thereby improving the overall operational safety and sustainability of industrial processes.

One notable advantage of resilient seated valves is their ability to adapt to fluctuating system demands. They exhibit excellent performance in handling both clean and dirty fluids, making them ideal for diverse applications, including water treatment and chemical processing. Traditional valves may require frequent maintenance and replacements due to potential damages caused by abrasive substances, while resilient seated valves significantly minimize these operational costs. Additionally, their lighter weight and simpler installation processes make them a more favorable choice for modern manufacturing environments striving for efficiency and cost-effectiveness.

Maintaining resilient seated valves is crucial for ensuring their longevity and optimal performance in industrial applications. As these valves play a vital role in controlling fluid flow, implementing proper maintenance practices can significantly enhance operational efficiency. Regular inspections and timely repairs can prevent minor issues from escalating into major failures, thereby minimizing downtime and associated costs.

**Tips:** One key practice is to frequently check for signs of wear or corrosion, particularly in areas that experience high stress or exposure to harsh conditions. Additionally, lubricating valve stems and connections can reduce friction and extend the life of the valve. It's also beneficial to stay updated with standards such as the ISA-75 series, which provides essential guidance on valve design and maintenance, helping professionals align their practices with industry best practices.

Another critical aspect of maintenance is routine testing to ensure that valves are functioning correctly. Implementing a regular testing schedule allows for the early detection of potential issues, ensuring that the valves operate effectively within their intended parameters. By proactively managing maintenance, facilities can keep resilient seated valves performing optimally and avoid unplanned outages.

| Maintenance Practice | Frequency | Expected Lifespan Increase (%) | Typical Cost ($) | Notes |

|---|---|---|---|---|

| Visual Inspection | Monthly | 5-10% | 50 | Check for wear, leaks, and corrosion |

| Lubrication of moving parts | Quarterly | 10-15% | 100 | Use recommended lubricants |

| Sealing surface cleaning | Biannually | 7-12% | 75 | Ensure effective sealing performance |

| Pressure Testing | Annually | 20-25% | 250 | Identify leaks before they become serious |

| Replacement of seals | As needed | 30-40% | 300 | Critical for maintaining valve function |

As the industrial landscape evolves, the integration of advanced valve technologies is becoming paramount to enhance efficiency. The global hydraulic valve market is projected to grow from $770 million in 2025 to $1.16 billion by 2033, highlighting a promising compound annual growth rate (CAGR) of 5.2%. This growth is fueled by the demand for resilient seated valves that not only optimize process performance but also ensure superior reliability and durability in various industrial applications.

Tips: Consider investing in cutting-edge valve technology to streamline operations and reduce maintenance costs. Moreover, staying informed about industry trends can help businesses anticipate shifts in market demands and adapt accordingly.

Another significant sector witnessing growth is the directional control valve market, expected to expand at a CAGR of 3.53% from $400 million in 2023 to $547 million by 2032. This trend indicates a strong movement towards automation technologies that enhance operational efficiency. The rise of micro-drives in industrial automation exemplifies how innovation is revolutionizing processes, propelling industries towards unprecedented levels of productivity.

Tips: Embracing automation can lead to significant operational improvements. Regularly evaluate your technological investments to ensure you are aligned with emerging trends and can leverage new opportunities for efficiency gains.

This chart illustrates the projected growth in industrial efficiency with the implementation of resilient seated valves from 2020 to 2024. As industries adopt advanced valve technologies, a steady increase in efficiency is anticipated, enhancing overall operational performance.