In the dynamic world of fluid systems, efficiency is paramount for optimal performance and reliability. One crucial component that significantly enhances system efficiency is the Duo-Check Valve. This innovative device not only prevents backflow but also streamlines the flow of fluids, making it an essential choice for various industrial applications. Understanding the multifaceted advantages of the Duo-Check Valve can aid engineers and designers in making informed decisions that contribute to both operational effectiveness and cost savings.

This article aims to highlight the top ten advantages of utilizing Duo-Check Valves in fluid systems. By examining their functionality, durability, and maintenance benefits, we will explore how these valves can lead to improved system performance. From reducing energy loss to minimizing downtime, the Duo-Check Valve proves to be a game-changer for ensuring uninterrupted fluid flow and protecting critical system components. Join us as we delve into the compelling benefits of this vital piece of engineering equipment, and discover strategies to enhance your fluid system's efficiency.

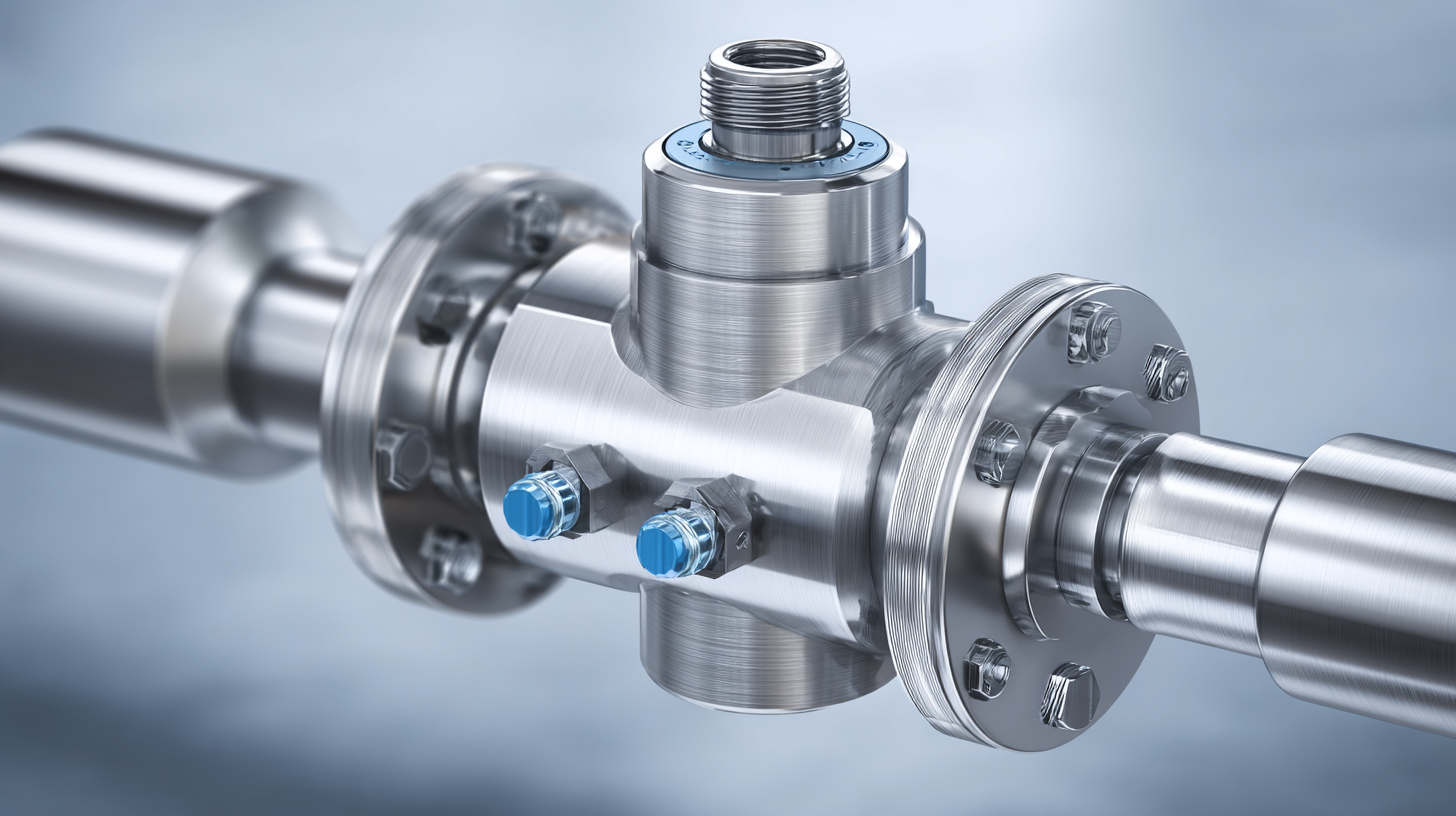

Duo-check valves play a crucial role in enhancing the efficiency of fluid systems, particularly through improved flow control and reduced pressure loss. Recent studies indicate that optimizing flow dynamics can significantly impact performance in various applications such as heat exchangers and water management systems. For instance, research on heat exchangers has demonstrated that the implementation of innovative designs, including enhancements like I-rib twisted tapes, can lead to a marked increase in thermal efficiency. This aligns with findings that suggest that effective flow control can reduce pressure drop, contributing to lower energy costs and improved system performance.

Furthermore, addressing pressure loss is not just about immediate gains; it also significantly influences the long-term sustainability of fluid systems. Investigations into fluid flow within valves, such as gate valves, indicate that managing turbulence and flow separation can lead to substantial improvements in overall system reliability. With the pressure drop in fluid systems often accounting for energy losses upwards of 30%, the implementation of advanced duo-check valve designs can result in both operational efficiencies and enhanced resilience against future challenges in fluid management. Adopting these technologies is essential for organizations aiming to improve their fluid handling systems' effectiveness while contributing to broader environmental sustainability goals.

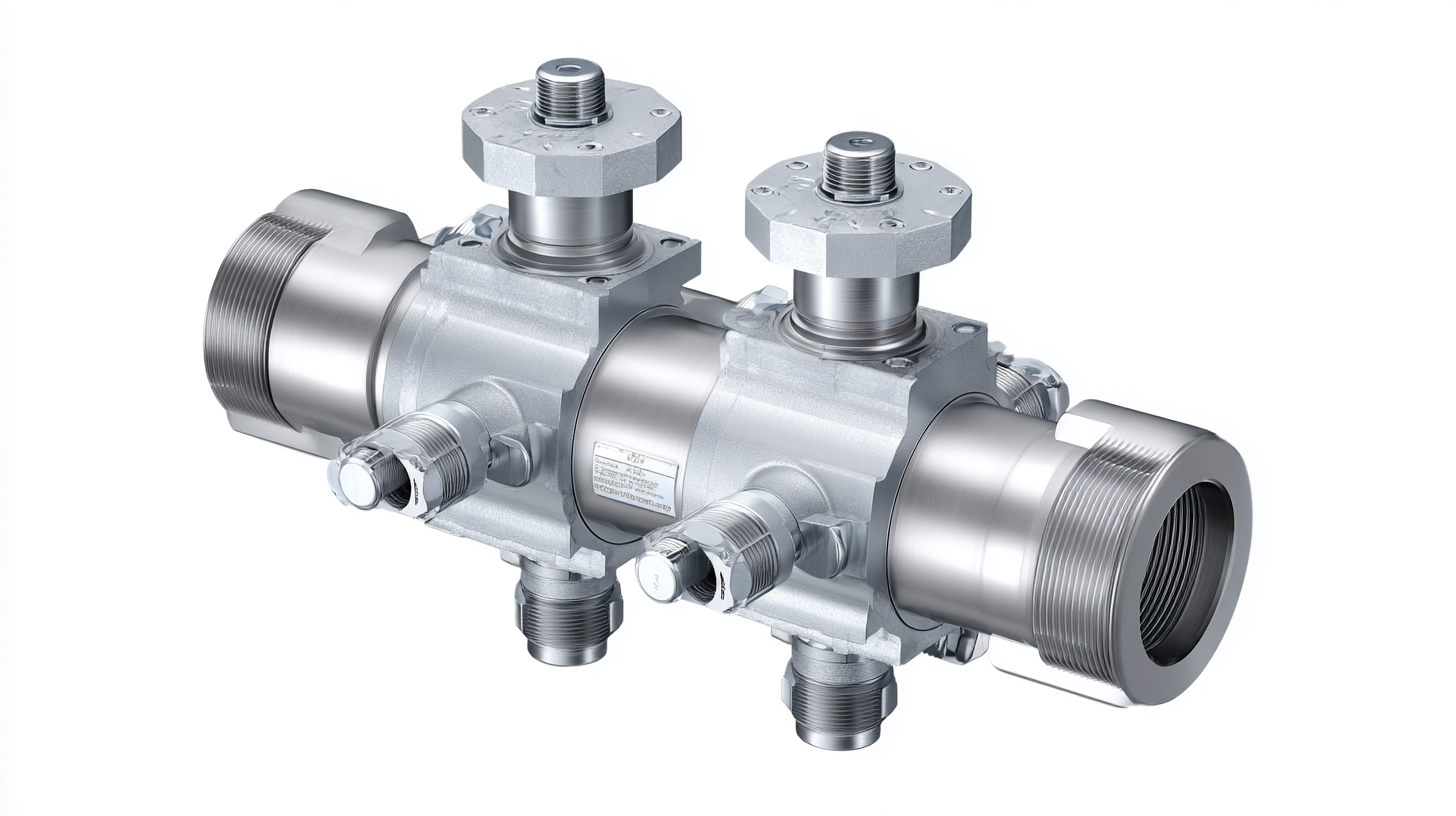

Duo-check valves play a pivotal role in fluid systems by significantly minimizing the risk of reverse flow. Unlike traditional single check valves, which can fail under certain conditions, duo-check valves are designed with two independent mechanisms that provide an additional layer of protection. This design ensures that even if one mechanism fails, the other remains operational, thereby preventing backflow and maintaining system integrity.

In addition to their robust design, duo-check valves are typically more reactive to fluid dynamics. Their ability to quickly respond to pressure changes helps to mitigate the effects of reverse flow, enhancing the overall efficiency of fluid systems. This is particularly crucial in applications where the integrity of the system could be compromised by reverse flow, such as in water treatment facilities or industrial piping systems. By choosing duo-check valves, engineers and system designers can ensure that processes run smoothly, maintain optimal performance, and reduce the risk of costly damage or operational failures.

Duo-check valves are essential components in fluid systems, renowned for significantly enhancing reliability and longevity. Unlike traditional valves, duo-check valves are designed to prevent backflow while ensuring that flow rates remain efficient under varying pressures. This unique mechanism contributes to the stability of the entire system, reducing the risk of potential leakages and system failures, which can lead to costly downtimes.

**Tip:** Regular maintenance of duo-check valves is crucial for optimal performance. Inspecting seals and internal parts can prevent unexpected breakdowns and ensure that the valves operate as intended.

Furthermore, duo-check valves are often constructed with durable materials that withstand harsh environmental conditions. This robustness not only extends the lifespan of the valve itself but also enhances the overall durability of the fluid system. With a reduction in wear and tear, operators can enjoy more dependable functionality, resulting in fewer interruptions and maintenance requirements.

**Tip:** Consider upgrading to premium duo-check valves if your fluid system operates under extreme conditions. Investing in high-quality materials can lead to greater efficiency and significant long-term savings.

Duo-check valves play a crucial role in enhancing the efficiency of fluid systems across various industries. Their versatile applications are evident in sectors such as automotive, construction, and manufacturing, where precise control of fluid flow is paramount. As industries shift towards more sustainable and reliable practices, these valves provide a solution that minimizes leaks and maximizes operational efficiency.

In line with the versatility of duo-check valves, recent innovations highlight how technology drives improvements in diverse industrial applications. For instance, a high-precision module has been introduced that streamlines system integration, showcasing the need for components that not only function effectively but also align with industry requirements for adaptability. Furthermore, advancements in materials, such as fine denier nonwovens, illustrate the growing demand for versatile solutions in construction and filtration.

**Tip:** When selecting a duo-check valve for your application, consider the specific requirements of your system, including pressure ratings and fluid types, to ensure optimal performance. Additionally, staying informed about emerging technologies can help you leverage innovative solutions that enhance your fluid management processes effectively.

| Advantage | Description | Applications | Industry |

|---|---|---|---|

| Prevent Backflow | Effectively stops the reverse flow of fluid, protecting downstream equipment. | Pipelines, tanks | Oil and Gas |

| Minimizes Pressure Loss | Designed to offer low resistance, ensuring efficient fluid transport. | Fluid transport systems | Water Supply |

| Easy Maintenance | Simplified design allows for quick inspection and servicing without system shutdown. | Industrial facilities | Manufacturing |

| Durability | Constructed from robust materials, offering long service life even in harsh environments. | High pressure systems | Chemical Processing |

| Versatile Design | Suitable for various orientations, allowing flexibility in installation. | Fluid control systems | Construction |

| Cost-Effective | Reduces operational costs through efficient prevention of leaks. | Water conservation systems | Utilities |

| Wide Temperature Range | Can operate effectively across a broad temperature spectrum. | Heating and cooling systems | HVAC |

| Low Maintenance Cost | Requires fewer repairs and replacements, ensuring lower ongoing costs. | Pumping stations | Water Management |

| Enhanced Safety | Reduces risk of accidents related to fluid backflow. | Emergency shutdown systems | Energy |

The importance of cost-effective solutions in maintenance and energy consumption is underscored by the projected growth in various industrial markets. For instance, the global fog collector market is anticipated to reach approximately $318.7 million in value by 2024, with an expected increase to $399.71 million by 2033, reflecting a compound annual growth rate (CAGR) of 2.57%. This growth highlights the increasing focus on efficient fluid management systems that utilize advanced technologies, such as duo-check valves, to enhance operational efficiency while minimizing maintenance costs.

Moreover, the SAG and AG mill markets are similarly poised for growth, expected to expand from an estimated $441.9 million in 2025 to $546.8 million by 2033, achieving a CAGR of 2.7%. Such trends signal an industry-wide shift towards optimizing energy consumption and reducing operational inefficiencies, ultimately contributing to long-term sustainability. As sectors continue to evolve, the integration of effective fluid systems will play a crucial role in achieving these cost savings and energy efficiencies, fostering a more resilient industrial infrastructure.