Choosing the right Silicone Rubber for your project can be challenging. Many types exist, each with unique properties. Understanding these characteristics is vital for success.

Silicone Rubber offers versatility and durability. It is resistant to extreme temperatures, chemicals, and UV exposure. However, not all Silicone Rubber is created equal. Some grades might not meet your project’s specific requirements. This can lead to failures that cannot be easily fixed.

Consider your project’s needs. Are you making seals, gaskets, or molds? The application will dictate the type of Silicone Rubber. Reflecting on your choices is essential. You might find that what seemed right initially doesn’t deliver the expected results in practice. Take the time to evaluate your options thoroughly.

When choosing the right silicone rubber, understanding its types and properties is crucial. Silicone rubber comes in various formulations, each designed for specific applications.

For example, high-temperature silicone can withstand temperatures exceeding 300°C, making it ideal for automotive and aerospace industries. On the other hand, medical-grade silicone is designed for biocompatibility, ensuring safety for use in healthcare applications.

Different types of silicone rubber exhibit distinct properties. For instance, addition-cure silicone offers superior flexibility and strength, while condensation-cure silicone is preferred for its ease of use during production. According to industry reports, the demand for silicone rubber is projected to grow at a CAGR of 6% from 2023 to 2030. This growth highlights the importance of selecting the right type for maximum efficiency.

It’s essential to consider the specific requirements of your project. Some applications call for UV resistance, while others may need enhanced tear strength. However, it's common to overlook these details, leading to suboptimal performance. Assessing these factors can help avoid costly mistakes, ensuring the silicone rubber chosen meets the project's needs.

When evaluating project requirements for silicone rubber, start by identifying key characteristics. Think about temperature resistance, flexibility, and durability. Each of these features plays a vital role in the overall success of your project. For example, high-temperature applications demand silicone that can withstand extreme heat without degrading.

Next, consider the environmental factors. Will the silicone be exposed to UV light, chemicals, or moisture? These elements can significantly affect the performance of the material. It's essential to match your choice with these conditions. If the environment is unpredictable, testing different options may be necessary.

Budget constraints often complicate the selection process. You want quality, but costs can add pressure. Finding a balance might require compromises. Sometimes, the least expensive option may not be the most effective in the long run. Reflecting on your priorities is crucial. What matters most: durability, cost, or specific functionality? Take the time to evaluate these aspects carefully to avoid frustration later.

When selecting silicone rubber for your project, several key factors come into play. Understanding the specific requirements of your application is crucial. For instance, the durometer, or hardness scale, can significantly impact performance. A recent report indicated that 60% of failures in projects were linked to improper hardness choices. It’s essential to determine whether you need softer rubber for flexibility or harder variants for durability.

Temperature resistance is another vital consideration. Silicone rubber can withstand extreme temperatures, from -60°C to 230°C. However, not all grades perform equally. Studies show that over 40% of industrial applications fail due to inappropriate thermal properties. Evaluating the environment where the silicone will be used can prevent costly mistakes.

Additionally, think about the chemical compatibility of silicone rubber. Some formulations can degrade when exposed to certain substances. In fact, a significant number of project delays stem from underestimating material interactions. Look into chemical exposure data relevant to your industry. By focusing on these aspects, you can greatly increase your chances of a successful project outcome.

| Property | Description | Importance |

|---|---|---|

| Temperature Resistance | Ability to withstand extreme temperatures without degradation. | High |

| Chemical Resistance | Resistance to various chemicals, oils, and solvents. | Medium |

| Hardness | Measurement of material stiffness, often measured in Shore A. | High |

| Tear Resistance | Ability to resist tearing when subjected to stress. | High |

| Flexibility | Ability to bend and stretch without breaking. | Medium |

| Aging Resistance | Resistance to degradation over time due to weathering and UV exposure. | High |

| Electrical Insulation | Ability to act as an insulator and resist electrical conductivity. | Medium |

| Food Safety | Compliance with safety standards for use in food applications. | High |

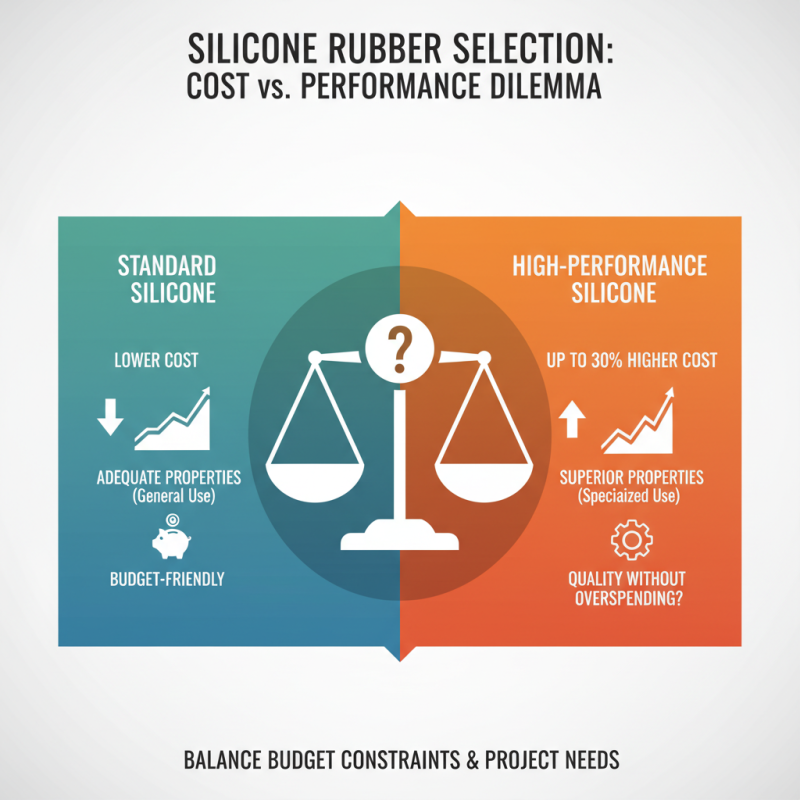

When selecting silicone rubber, the cost versus performance dilemma often surfaces. Many projects require a careful balance between budget constraints and necessary physical properties. A recent industry report revealed that high-performance silicone can cost up to 30% more than standard options. This comparison can pose challenges for project leads who need quality without overspending.

Performance factors such as heat resistance and tensile strength are critical in many applications. High-performance silicones may offer tensile strengths exceeding 10 MPa. In contrast, standard options might only provide around 5 MPa. Choosing a budget silicone might save money initially but could lead to higher costs later due to failures or replacements. It's a consideration that can’t be overlooked.

However, not all projects require top-tier materials. For some applications, standard silicone may perform adequately at lower costs. Engineers must weigh the long-term implications of their decisions. It's essential to assess specific project requirements and how potential failures impact budget and timelines. This analysis allows for more informed silicone selections tailored to project needs rather than simply opting for the cheapest option available.

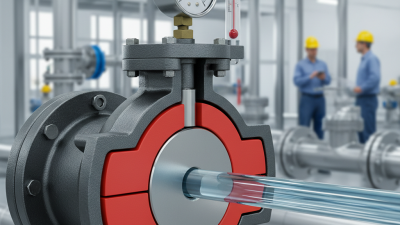

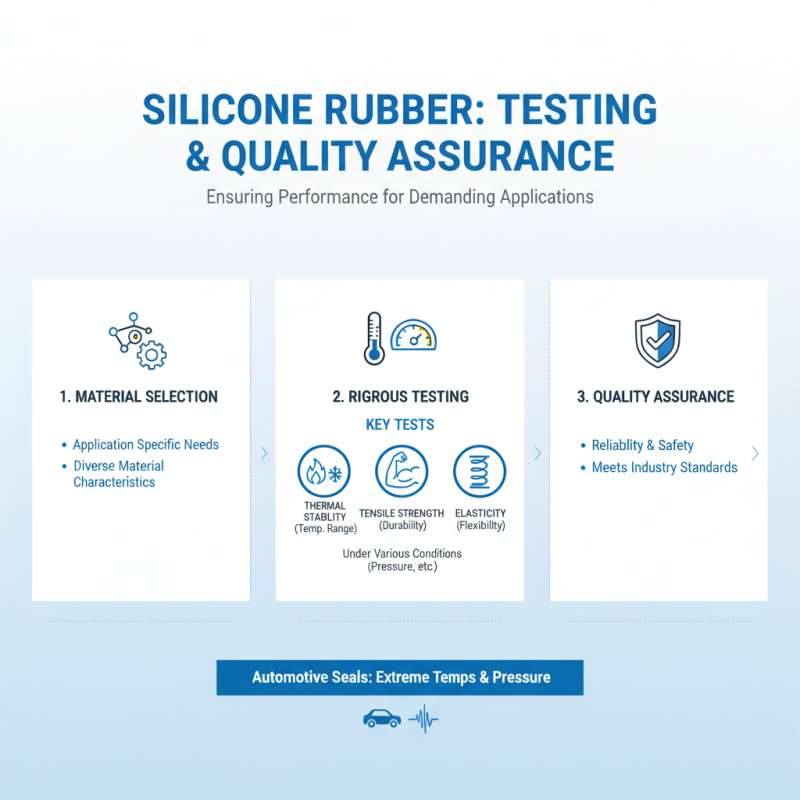

When selecting silicone rubber, testing and quality assurance play crucial roles. Each application demands specific characteristics from the material. This often requires thorough testing to ensure performance under various conditions. For instance, a silicone rubber used in automotive seals must endure significant temperature variations and pressures. Testing should include thermal stability, tensile strength, and elasticity.

Quality assurance begins with consistent materials. Variations in color and texture may not meet project standards. Regular inspections must occur during production to catch these inconsistencies. However, discrepancies may still arise. An unexpected batch could lead to different performance results. Therefore, establishing clear quality benchmarks is vital.

Documenting the performance metrics is essential. Data collection helps identify trends and areas needing improvement. This feedback loop supports continuous enhancement of both the material and the testing processes. Nevertheless, achieving absolute perfection is challenging. Reflection on past tests and outcomes is necessary for future success. Building a robust quality assurance process is not only about meeting standards; it's an ongoing commitment to excellence.