In the world of industrial applications and manufacturing, the choice of the right materials can greatly influence project outcomes, with silicone gaskets emerging as a preferred option across various sectors. According to a report by MarketsandMarkets, the global gasket market is projected to reach $16.6 billion by 2026, driven by the increasing demand for efficient sealing solutions. Silicone gaskets, known for their resilience in extreme temperatures, chemical resistance, and flexibility, play a critical role in ensuring optimal performance and durability in applications from automotive to aerospace. As industries strive for improved product integrity and sustainability, understanding how to select the right silicone gasket becomes essential. This guide aims to provide comprehensive insights into choosing the ideal silicone gasket for your specific project needs, ensuring both functionality and reliability in your applications.

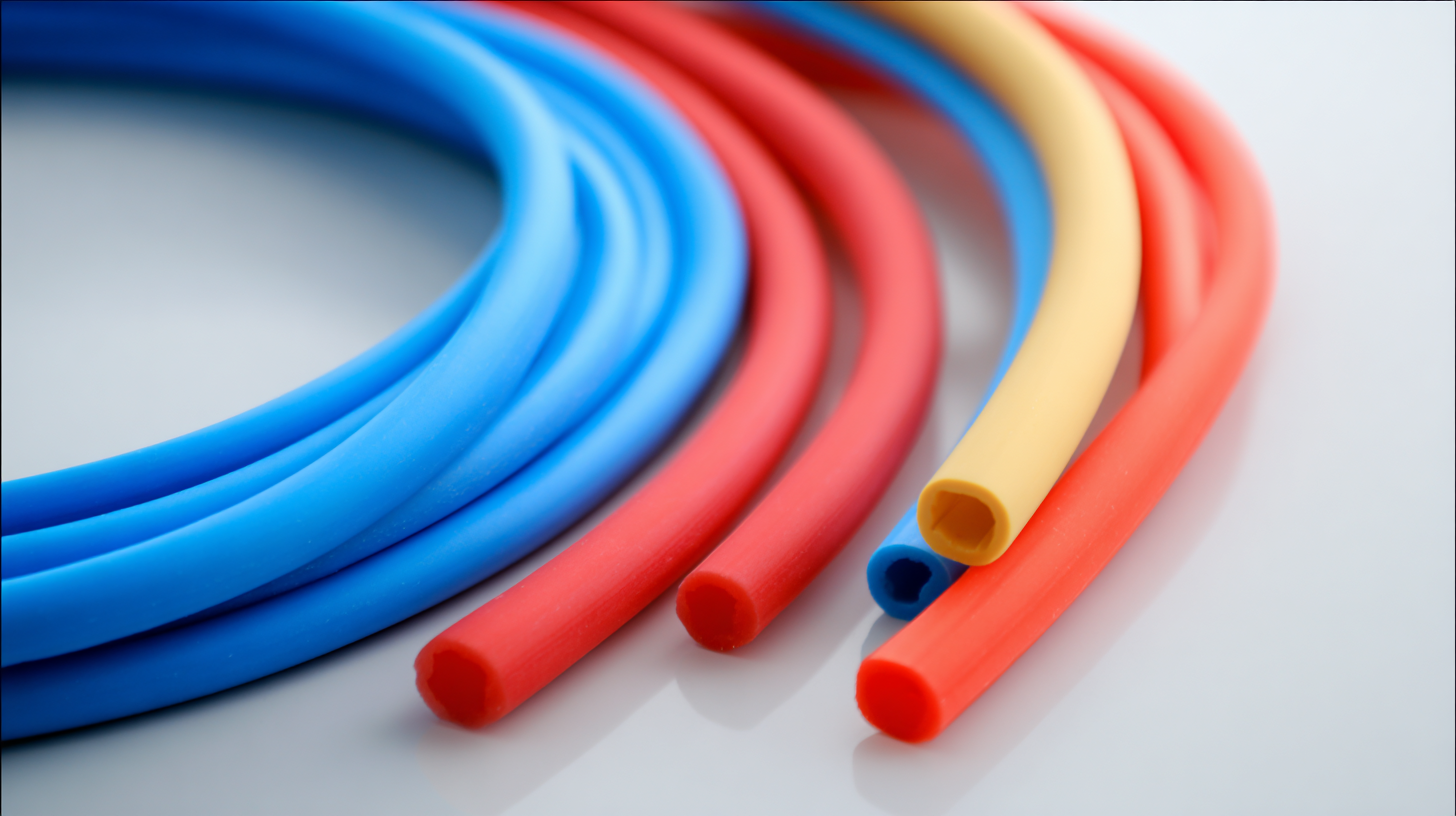

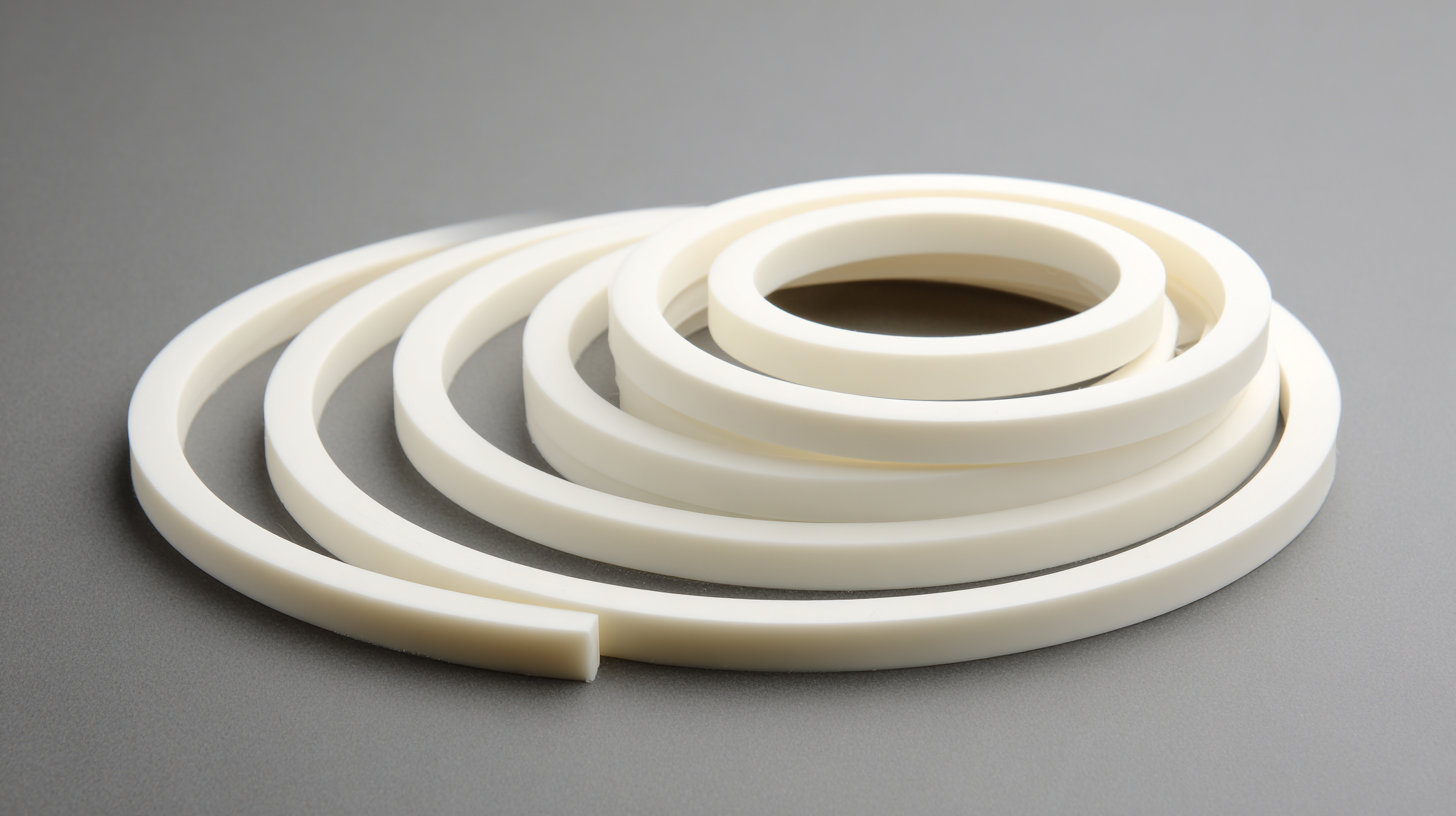

When selecting a silicone gasket for your project, it’s crucial to understand the various types available and their specific applications. Silicone gaskets can be broadly categorized into solid silicone gaskets, sponge silicone gaskets, and custom molded gaskets. Solid silicone gaskets provide excellent durability and resistance to extreme temperatures and chemicals, making them ideal for high-performance scenarios. Their rigid structure ensures a tight seal, which is particularly useful in environments exposed to oil and gas.

On the other hand, sponge silicone gaskets offer greater compressibility and flexibility. These gaskets are better suited for applications where minor irregularities in surfaces need to be accommodated, ensuring a reliable seal even under less-than-perfect conditions. Furthermore, custom molded gaskets can be tailored to fit specific shapes and sizes for unique applications, offering the advantage of a precise fit and optimal sealing performance. Each type of silicone gasket presents distinct benefits, allowing users to select the most fitting option based on their project requirements.

When selecting a silicone gasket for your project, several key factors must be considered to ensure optimal performance and longevity. One primary factor is the temperature resistance of the silicone material. According to the “Silicone Materials Market Report 2023,” high-quality silicone gaskets can withstand temperatures ranging from -60°C to 200°C, offering significant flexibility in various applications, from automotive to industrial machinery. Therefore, assessing the operating temperatures of your specific project helps in choosing the right material.

Another crucial aspect is the chemical compatibility of the gasket material. A study published in the "Journal of Applied Polymer Science" notes that silicone gaskets exhibit excellent resistance to a variety of chemicals, including oils, fuels, and certain solvents. Understanding the chemical environment your gasket will be exposed to is vital, as a suitable silicone must be chosen to prevent material degradation and ensure reliability. Finally, the gauge of the gasket should match the needs of your application, factoring in sealing pressure and fluid dynamics to avoid leaks and maintain system efficiency. Proper attention to these factors will set the stage for a successful project.

When selecting the right silicone gasket for your project, precise measurements are crucial for achieving the perfect fit. To ensure accuracy, start by determining the dimensions of the surface where the gasket will be installed. Measuring the length, width, and thickness of both the mating surfaces will help you identify the correct gasket profile. According to industry standards, a proper fit can reduce the likelihood of leaks and enhance the durability of the assembly. A survey conducted by the Gasket & Sealing Products Association suggests that improperly fitted gaskets can lead to a 25% increase in maintenance costs over time due to frequent replacement and system downtime.

Additionally, consider the operating conditions your gasket will face. Factors such as temperature fluctuations, pressure levels, and exposure to chemicals can significantly affect gasket performance. For instance, a report by the International Sealing Association highlights that silicone gaskets excel in high-temperature environments, maintaining integrity in temperatures ranging from -50°F to 500°F. By understanding the specific requirements of your project and the capabilities of silicone materials, you can select a gasket that not only fits perfectly but also withstands the demands of its operational environment.

Silicone gaskets are versatile components used across numerous industries, thanks to their excellent temperature resistance and flexibility. In the automotive sector, they play a crucial role in sealing engine components, preventing leaks while ensuring optimal performance under high-pressure conditions. Similarly, in the food and beverage industry, silicone gaskets provide food-safe sealing solutions, protecting against contamination while meeting strict regulatory standards.

When selecting the right silicone gasket for your specific application, keep in mind a few essential tips. First, ensure the gasket material is compatible with the substances it will encounter, particularly in terms of temperature and chemical exposure. Second, consider the thickness and hardness of the gasket, as these factors impact its ability to create an effective seal. Lastly, always verify that your silicone gasket meets industry regulations, especially if it will be used in sensitive environments like healthcare or food processing.

In the electronics industry, silicone gaskets are invaluable for sealing enclosures against moisture and dust. Their durability and resistance to extreme temperatures make them ideal for protecting sensitive components, ensuring reliable performance in various applications, from consumer gadgets to industrial machinery. With the right choice, silicone gaskets can significantly enhance the lifespan and integrity of your projects across different sectors.

Maintaining and replacing silicone gaskets is crucial for ensuring the longevity and efficiency of various applications, from automotive to industrial machinery. According to the "Silicone Gasket Market Analysis 2022" by Grand View Research, the global silicone gasket market is projected to reach $2.6 billion by 2025, highlighting the growing importance of these components in different sectors. Regular maintenance practices, such as inspecting for wear and tear and ensuring proper sealing, can significantly extend the lifespan of silicone gaskets. Industry experts suggest that gaskets should be replaced every 3 to 5 years, depending on the environment and application, to prevent leaks and ensure optimal performance.

When it comes to replacement, it is essential to select the right type of silicone gasket designed for the specific application. A study by the Rubber Manufacturers Association reveals that approximately 40% of gasket failures can be traced back to incorrect material selection. Factors such as temperature resistance and chemical compatibility must be considered. Additionally, following proper installation guidelines will help avoid common pitfalls that lead to premature failure, thereby saving time and costs in the long run. By adhering to these maintenance and replacement tips, businesses can enhance operational efficiency and prevent costly downtimes associated with gasket failures.