Choosing the right rubber washers is crucial for various projects. These small yet essential components play a significant role in preventing leaks and ensuring a tight seal. You may find them in plumbing, automotive, and household applications. Rubber washers come in many sizes, shapes, and materials. This diversity can make selection challenging.

When selecting rubber washers, consider the specific requirements of your project. For instance, different types of rubber provide varying levels of durability and resistance. Natural rubber is flexible, while synthetic options can offer better weather resistance. You might also encounter terms like shore hardness. This refers to the firmness of the rubber, which can impact its performance.

Be mindful of your choices. Sometimes, the cheapest option may not be the best for your needs. It’s easy to overlook quality for cost. Yet, a poor-quality washer can lead to failures or leaks. Take the time to reflect on what you truly need. Assess your project requirements carefully before making a decision. Rubber washers may seem simple, but the right choice can make a significant difference in your project's success.

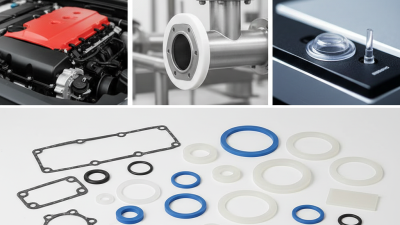

When selecting rubber washers, it's crucial to understand the types available. There are various materials, each serving a specific purpose. For example, Neoprene washers are great for water resistance. They are durable, but not ideal for extreme temperatures. Vinyl washers, on the other hand, are versatile. They can handle both hot and cold conditions, making them a popular choice for many projects.

Another option is silicone washers. They offer excellent elasticity and can withstand high temperatures. However, they may wear out faster under constant pressure. Remember, each type has its pros and cons. Rubber hardness is also vital. Softer washers can absorb shock well but might deform with heavy loads. Harder washers provide more support but can lead to leaks if not fitted correctly.

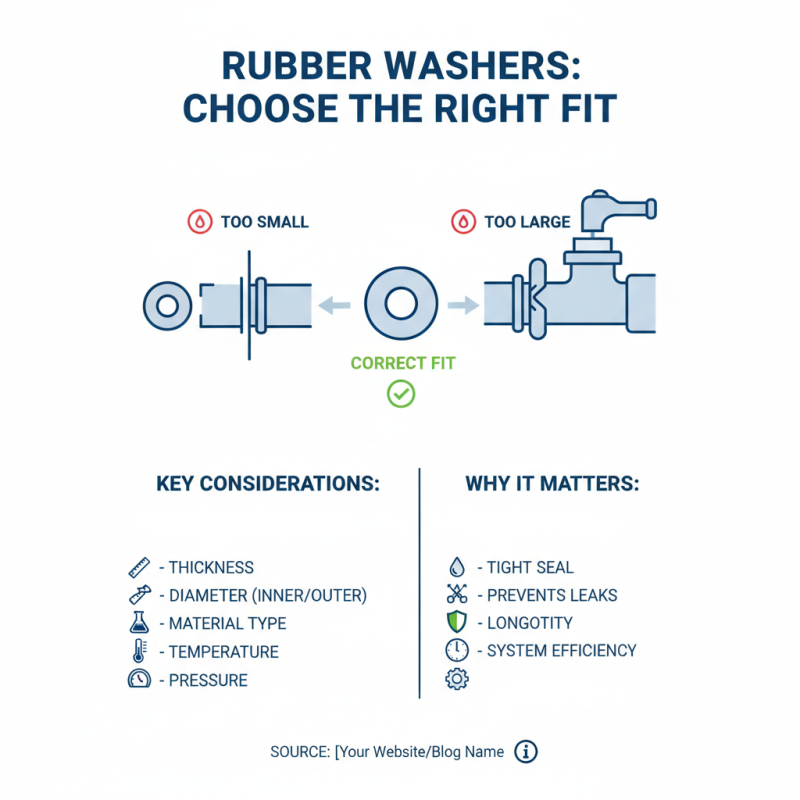

Don't overlook the size and thickness of the washer. A washer that's too small won't seal properly. Alternatively, an oversized washer may not fit in tighter spaces. It's easy to overlook these details during selection. Testing in real conditions can reveal unforeseen issues. Ultimately, understanding these aspects of rubber washers can significantly enhance project outcomes.

Choosing the right rubber washers can significantly impact your project's outcome. Start by considering the application. What environment will the washers be in? For wet or harsh conditions, other materials may fail, while rubber can provide necessary durability. The size of the washers matters too. Measure carefully. A washer that's too small won’t seal properly, and one that is too large can lead to friction issues.

Next, think about the rubber type. Not all rubber is the same. Some are more resistant to heat, while others are better for chemicals. If you are unsure, testing a few options can be beneficial. However, this takes time and resources.

The thickness of the washer can also influence its performance. A thicker washer may seem stronger, but it can actually restrict movement. This can lead to stress on the surrounding parts.

Consider your budget, but avoid compromising quality. Cheaper options might not last long and could cause more issues later. Don’t overlook the importance of proper installation. No matter how good the washer is, poor installation can ruin its effectiveness. Reflect on these factors to avoid costly mistakes.

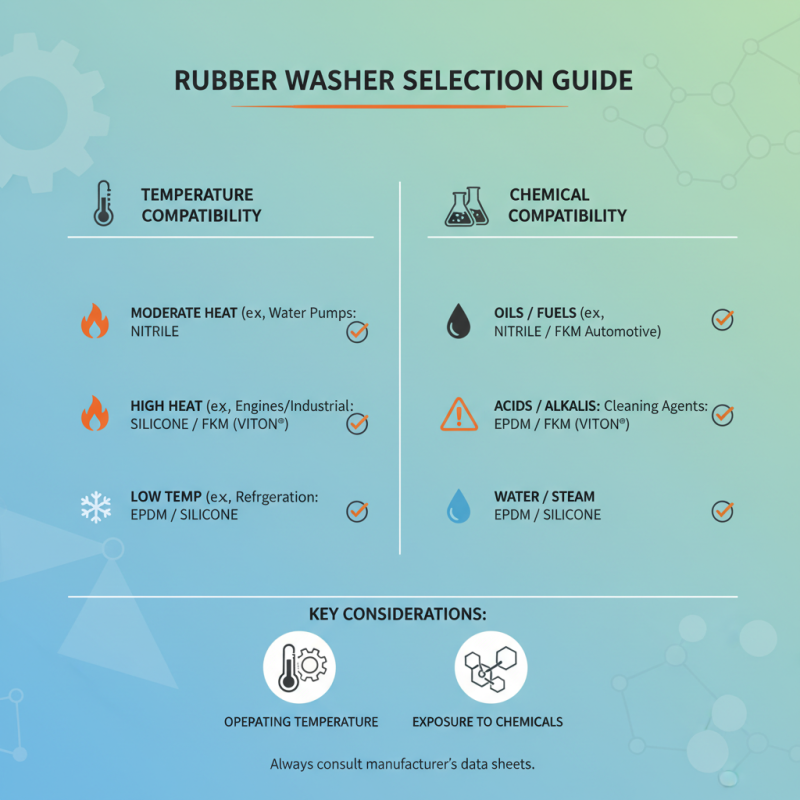

This chart illustrates various factors to consider when choosing rubber washers for different projects. Understanding the significance of each factor can help you make informed decisions based on your project needs.

Choosing the right rubber washers requires careful consideration of size and dimensions. Rubber washers come in various thicknesses and diameters. A proper fit ensures a tight seal in your project. If the washer is too small, leaks may occur. If it’s too large, it may not seat properly. This can lead to bigger issues.

Measuring is critical. Use calipers for accurate dimensions. Check the inner and outer diameters. Thickness matters too. A thicker washer often offers better cushioning. However, it can also raise the assembly height. This can impact how components interact. Sometimes, you might get it wrong. You may buy a size that seems perfect but doesn’t fit well.

Experiment with different sizes. Keep a few on hand for trial and error. Each project might require adjustments. Also, remember that rubber can wear over time. Periodic evaluations of your washer choices can help maintain effectiveness. There’s always room for improvement.

Choosing the right rubber washers requires careful consideration of temperature and chemical compatibility. Different rubber materials react differently under varying conditions. For instance, nitrile rubber performs well in moderate temperatures but deteriorates in extreme heat. Evaluating often reveals that what works at one temperature might fail at another.

Chemical exposure is another critical factor. Some rubber types resist oils and certain chemicals better than others. For example, silicone rubber offers excellent resistance to a broader range of substances compared to other materials. However, it might not withstand certain solvents. This inconsistency can lead to premature failure, leaking, or even equipment damage.

Consider the specific conditions your project will encounter. Test under actual working temperatures and chemical exposures. This process can unveil surprises. Misjudgments in material choice can lead to disruptions and additional costs. Balancing these elements is essential to ensure your project runs smoothly without setbacks.

When it comes to installing rubber washers, precision is key. These washers are essential for sealing applications to prevent leaks and ensure durability. According to industry reports, proper installation can reduce failure rates by up to 30%. The material choice greatly impacts the washer's performance. Consider the environment where the washer will be used. High temperatures may degrade certain rubber types, while others may withstand them better.

Tips: Always clean the surface before installation. Dirt can compromise the seal. If possible, test the compatibility of the rubber with substances it will encounter. This simple step can save time and resources.

Remember that over-tightening can lead to deformation. Avoid this common mistake. Research indicates that many failures occur due to improper torque settings. A calibrated wrench can make a significant difference. Use it for a consistent application of force. Take the time to read specifications; it is worth it.

In some cases, rubber washers may not perform as expected. Reflect on the potential causes. Was the right size chosen? Did environmental factors play a role? Identifying these issues can help in future projects. Always strive to improve.

| Application | Material Type | Temperature Range (°C) | Durometer Hardness | Best Practices |

|---|---|---|---|---|

| Plumbing | Nitrile Rubber | -30 to 100 | 70-80 Shore A | Ensure a tight fit; use lubricant on threads. |

| Automotive | EPDM Rubber | -40 to 120 | 60-70 Shore A | Check for wear; replace if cracked or brittle. |

| Industrial Equipment | Silicone Rubber | -60 to 200 | 40-60 Shore A | Use appropriate pressure; avoid over-compression. |

| Electrical Insulation | Neoprene Rubber | -20 to 80 | 50-60 Shore A | Ensure clean surfaces; avoid moisture. |