In the world of fluid control, selecting the appropriate valve for a specific application can be a crucial decision that impacts operational efficiency and safety. Among the various types of valves available, the Resilient Seated Valve stands out due to its unique ability to offer excellent sealing and durability. According to industry expert Dr. Jane Smith, a leading authority on valve technologies, “Choosing the right resilient seated valve can mean the difference between seamless operation and costly downtime.”

The intricacies involved in this selection process require careful consideration of multiple factors, such as pressure ratings, temperature tolerances, and the nature of the media being transported. A well-chosen resilient seated valve not only enhances functional performance but also contributes to long-term cost savings by minimizing maintenance needs.

As different applications demand varied specifications, understanding the unique attributes of resilient seated valves becomes imperative. From municipal water systems to industrial applications, this guide aims to equip readers with the knowledge needed to make an informed choice, ensuring optimal performance in their specific operational settings.

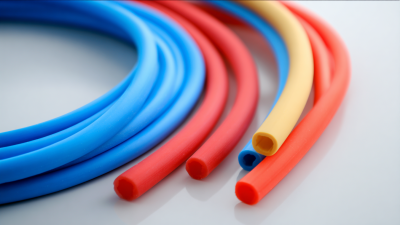

Resilient seated valves are essential components in various industrial applications, providing reliable control over the flow of fluids. These valves are designed with a soft, elastomeric material seated against a metal disc, offering a tight seal that minimizes leakage. This functionality makes them ideal for handling both water and wastewater, as well as services involving aggressive or corrosive fluids. Their design allows for smooth operation, reduced friction, and lower actuation forces, which enhances their overall efficiency in fluid management systems.

In addition to their sealing capabilities, resilient seated valves are known for their adaptability across different working conditions. They can effectively operate in a wide range of pressures and temperatures, making them suitable for diverse industries, including plumbing, HVAC, and fire protection systems. The ease of installation and maintenance is another significant advantage, as many of these valves can be serviced without removing them from the pipeline. Understanding these aspects of resilient seated valves is crucial for selecting the right product for specific applications, ensuring optimal performance and longevity in system operations.

When selecting resilient seated valves for specific applications, various key factors play a critical role in ensuring optimal performance and longevity. One primary consideration is the valve's pressure rating, which determines its ability to withstand the operating conditions of the system. Understanding the maximum and minimum pressures that a valve will encounter helps in selecting a suitable model that can maintain integrity under stress.

Another essential factor is the type of medium that the valve will control. Different materials used in the construction of resilient seated valves have varying degrees of compatibility with fluids, gases, and slurries. It’s important to assess the chemical properties of the medium, including temperature and pH, to choose a valve that offers the necessary resistance against corrosion and wear. Furthermore, the expected flow rate and operating temperature can influence the design and features of the valve, impacting how efficiently it functions within the system.

Lastly, the installation environment must not be overlooked. Factors such as space constraints, accessibility for maintenance, and the orientation of the valve can influence the selection process. A valve that is easy to install and maintain can save time and costs in the long run. Ensuring the valve's compatibility with existing piping and systems is crucial for seamless integration and optimal operational efficiency. By carefully weighing these factors, one can select the right resilient seated valve tailored to the specific requirements of their application.

| Factor | Description | Importance | Recommended Material |

|---|---|---|---|

| Pressure Rating | The maximum pressure the valve can withstand without failure. | High | CS, SS |

| Temperature Range | The operating temperature range suitable for the valve material. | High | EPDM, Nitrile |

| Fluid Type | The nature of the fluid flowing through the valve (e.g., water, oil, chemicals). | Critical | PVC, CPVC |

| Size | The diameter and dimensions of the valve required for the application. | Medium | Varies by application |

| Actuation Method | The method used to operate the valve (manual, electric, pneumatic). | Medium | Depends on application |

When selecting a resilient seated valve for specific applications, it is crucial to understand the various types available and their corresponding uses. Resilient seated valves can be categorized into different types, including gate valves, ball valves, and butterfly valves, each serving distinct functions in fluid control systems. According to a market report by MarketsandMarkets, the global valve market is projected to grow significantly, with resilient seated valves expected to comprise a substantial portion of this growth due to their versatility and efficiency in diverse industries such as water supply, wastewater treatment, and chemical processing.

Gate valves are designed for minimal pressure loss and are ideal for on/off control in large pipelines, making them suitable for waterworks and air pollution control systems. In contrast, ball valves offer quick sealing and precise flow control, making them an excellent choice for industrial applications that require frequent operation. Meanwhile, butterfly valves are favored for their space-saving design and lightweight characteristics, often used in large-scale HVAC systems and bulk handling processes. According to recent studies, around 30% of industrial facilities are opting for butterfly valves due to their ease of installation and maintenance.

Understanding the specific operational requirements, such as pressure, temperature, and the nature of the fluid, is essential for choosing the right valve type. The right resilient seated valve not only enhances system efficiency but also ensures long-term reliability and safety in various applications, as highlighted by the American Society of Mechanical Engineers, which emphasizes the significance of proper valve selection in piping systems.

When selecting a resilient seated valve for your application, the installation and maintenance practices you employ can significantly affect the valve's long-term performance. According to the Valve Manufacturers Association, improper installation is one of the leading causes of valve failure, contributing to an estimated 30% of maintenance costs in industrial settings. Therefore, it is crucial to follow best practices during installation, which include ensuring that the valve is appropriately aligned and that the pipeline system is free from any debris. Additionally, applying the correct torque to the valve's body can prevent leaks and ensure optimal operation.

Routine maintenance is equally vital in prolonging the lifespan of resilient seated valves. Studies indicate that regular inspection and maintenance can reduce unexpected valve failures by up to 40%. To achieve this, operators should establish a maintenance schedule that includes checking for signs of wear, tightening connections, and testing for leaks. The use of predictive maintenance technologies, such as vibration analysis and thermal imaging, can offer early warnings of potential issues, allowing for proactive measures before a failure occurs. By prioritizing both installation accuracy and ongoing maintenance, facilities can enhance the reliability and efficiency of their resilient seated valves, ultimately leading to improved operational performance.

When selecting resilient seated valves for your system, one of the most common mistakes is not fully understanding the application's specific requirements. Failing to assess factors such as pressure, temperature, and fluid characteristics can lead to selecting a valve that may not perform efficiently or safely. It's crucial to conduct a thorough analysis of these parameters to ensure compatibility and optimal functionality. Ignoring the service conditions can result in premature failure, increased maintenance costs, and potential system downtime.

Another prevalent error is neglecting to consider the valve's material selection. Different materials have varying levels of corrosion resistance, longevity, and adaptability to different media. Selecting the wrong material can lead to chemical degradation or physical wear, significantly affecting the valve's performance. Additionally, overlooking the importance of a proper size can cause issues such as inadequate flow control or pressure drops within the system. Taking the time to evaluate these factors will lead to a more informed decision when choosing the right resilient seated valve for your application.