In the realm of industrial applications, the selection of a suitable check valve is critical for ensuring system efficiency and reliability. According to a recent market report by Research and Markets, the global check valve market is projected to reach USD 3.7 billion by 2025, highlighting the growing significance of these components in various sectors such as oil and gas, water and wastewater, and power generation. The right check valve is essential not only for preventing backflow but also for optimizing operational performance and reducing maintenance costs. As industries continue to concentration on enhancing safety and environmental compliance, understanding the intricacies of check valve specifications, materials, and applications becomes increasingly important.

This essential guide aims to provide insights and best practices for selecting the appropriate check valve for diverse industrial needs, ensuring that your systems operate smoothly and efficiently.

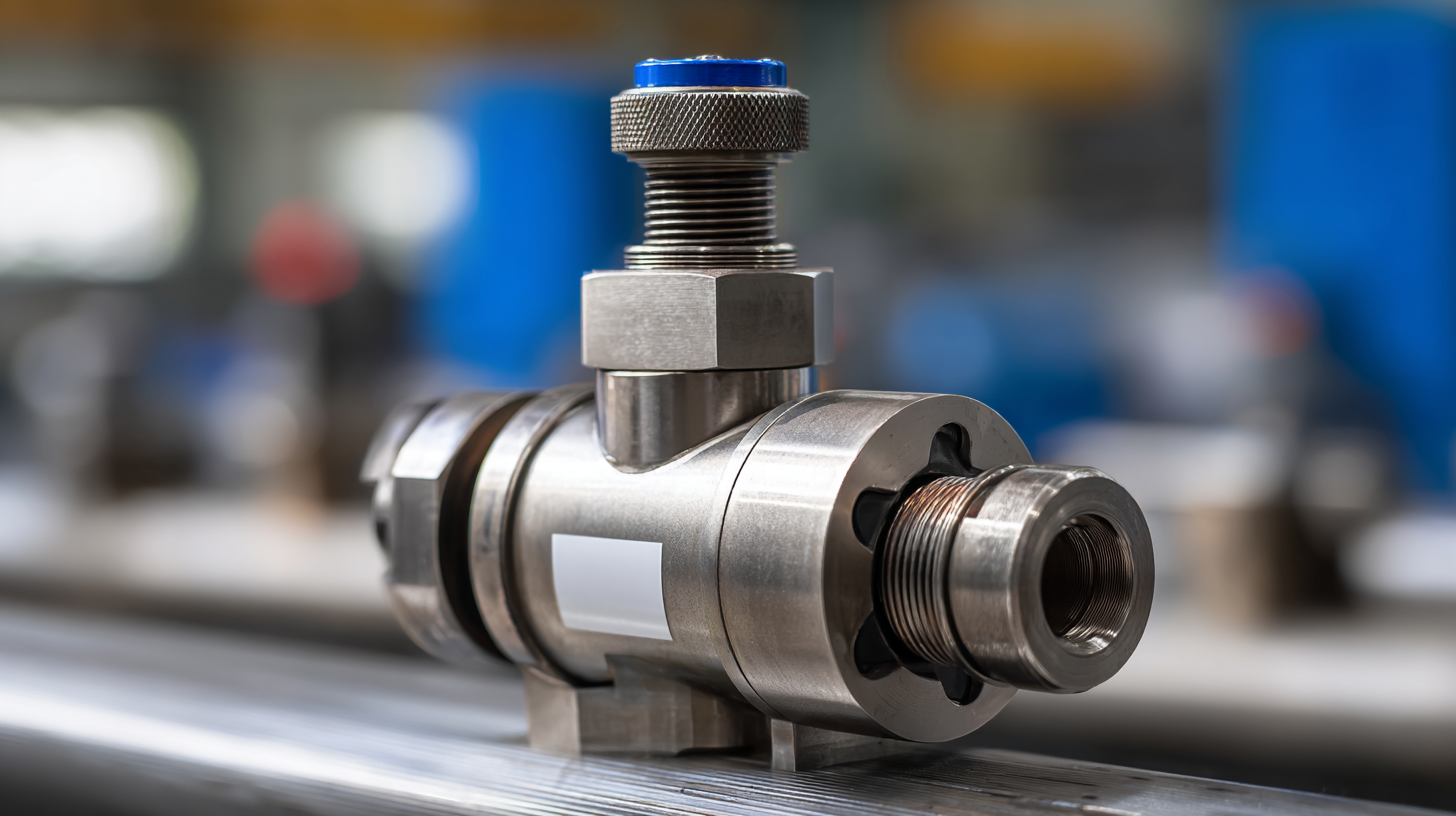

When selecting a check valve for industrial applications, understanding the various types available is crucial. Check valves are designed to allow flow in one direction while preventing backflow, which can lead to equipment damage and operational inefficiencies. The most common types include swing check valves, lift check valves, and diaphragm check valves, each catering to specific operational needs and fluid characteristics.

Swing check valves utilize a hinged disc that opens with forward flow and closes with reverse flow, making them ideal for larger diameter pipes and high flow rates. On the other hand, lift check valves work by moving a disc upwards off its seat in response to flow, suitable for high-pressure systems. Diaphragm check valves, featuring a flexible diaphragm that seals against the valve body, are often used in applications requiring a tight seal and are particularly effective in handling slurries or viscous fluids. Understanding these differences allows for a more informed decision when selecting the right check valve, ensuring optimal performance and longevity in industrial environments.

| Type of Check Valve | Description | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Swing Check Valve | Utilizes a disc that swings on a hinge to allow flow in one direction. | Water supply, sewage systems, and HVAC applications. | Simple design, low pressure drop, and effective sealing. | Susceptible to slamming and water hammering. |

| Lift Check Valve | A disc is lifted off its seat by flow pressure and falls back to close. | High-pressure applications and vertical pipelines. | Good for high-pressure flows and compact design. | Higher pressure drop compared to other types. |

| Duckbill Check Valve | A flexible valve made of rubber or elastomer that opens with flow pressure. | Sewage, stormwater management. | Self-cleaning, no moving parts, and low maintenance. | Limited to certain pressure and flow conditions. |

| Ball Check Valve | Uses a spherical ball that moves up and down to allow or stop flow. | Piping systems, process industries. | Reliable sealing and can handle higher flow rates. | Complex design may cause higher costs. |

| Piston Check Valve | Involves a piston that moves to allow or stop flow. | Oil and gas applications, high velocity flows. | Can handle high pressure and flow rates effectively. | More expensive and requires more maintenance. |

When selecting a check valve for industrial applications, it's crucial to consider several key factors that influence performance, reliability, and system integration. First and foremost, the application's specific requirements—such as fluid type, pressure, and temperature—should dictate the material and design of the check valve. For instance, in applications involving aggressive or corrosive fluids, materials with high resistance are essential to prevent degradation and ensure long-term efficiency.

Additionally, the valve’s flow characteristics play a significant role in its selection. A check valve must provide minimal pressure drop while ensuring that backflow is effectively prevented. Implementing tools that utilize advanced computational modeling can help simulate various operational scenarios, optimizing the choice of valves for specific systems. Furthermore, adhering to industry standards, as outlined in frameworks like the ISA-75 and ISA-96 series, ensures that the selected check valves comply with safety, performance, and efficiency requirements, ultimately contributing to a more robust operational environment.

When selecting a check valve for industrial applications, it's crucial to assess the flow requirements and pressure ratings to ensure optimal performance. According to a report by the Fluid Control Institute, improper sizing can lead to inefficiencies and increased operational costs, particularly in processes that involve fluctuating pressures and flow rates. For example, a check valve with a flow coefficient (Cv) unsuitable for the application can cause excessive pressure drops, leading to equipment failure or system downtime.

Understanding the specific flow requirements is key. The American National Standards Institute (ANSI) recommends that operators calculate the expected flow rates, considering factors such as temperature and fluid characteristics. This ensures that the chosen check valve can handle the system's demands. Additionally, pressure ratings should align with the maximum system pressure, given that check valves are typically exposed to dynamic conditions. The latest ASME guidelines highlight that selecting a valve rated for at least 1.5 times the maximum system pressure can enhance durability and performance in high-stress environments. By meticulously evaluating these parameters, industries can significantly improve the reliability and longevity of their check valves, ultimately leading to enhanced operational efficiency.

When selecting check valves for industrial applications, material compatibility is paramount to ensuring long-term performance and reliability. The choice of materials directly influences the valve's resistance to corrosion, temperature fluctuations, and chemical interactions present in specific systems. For instance, with the increasing focus on hydrogen and other demanding applications, manufacturers are prioritizing materials that can withstand harsher conditions. Reports indicate that materials such as stainless steel, PVC, and specialized alloys are gaining traction due to their durability and compatibility with a wider range of fluids.

Tips for ensuring effective material selection include conducting a thorough analysis of the operating environment and fluid composition. Always consider factors such as pH levels, temperature extremes, and the presence of particulates, which can significantly affect valve performance. The industry trend towards adopting advanced materials cannot be overlooked; recent studies highlight that materials like polymer composites are becoming essential in applications requiring lightweight yet strong valve components.

Additionally, regular certification and compliance with industry standards play a crucial role in material selection. Many manufacturers are now focusing on certifications that ensure their products meet rigorous safety and efficiency benchmarks. Utilizing certified valves not only helps to mitigate risks but also aligns with best practices in industrial design and operation, promoting sustainability in chemical and petrochemical systems.

When it comes to installing check valves in industrial applications, avoiding common mistakes is crucial for ensuring optimal performance. One prevalent error is improper orientation during installation. Check valves are designed to allow flow in one direction, and failing to orient them correctly can lead to backflow, inefficient operation, or even system failure. Always consult the manufacturer's guidelines and ensure that the flow arrow on the valve aligns with the system's intended flow direction to prevent such issues.

Another mistake often encountered is neglecting to consider the surrounding environment. Factors such as temperature and pressure can significantly impact a valve's performance. Installing a check valve that isn't rated for the specific conditions can lead to premature wear or catastrophic failure. Adequate support and alignment during installation are also vital. Using the right fittings and ensuring that the valve is securely mounted can prevent unnecessary stress on the valve body, extending its life and maintaining system integrity. By avoiding these common pitfalls, you can significantly enhance the reliability and efficiency of your industrial applications.