Choosing the right vulcanized rubber for your project in 2025 is a critical decision that can significantly impact the performance and longevity of your application. As industries continue to evolve, the demand for specialized materials that offer durability, flexibility, and resistance to environmental factors is on the rise. Vulcanized rubber stands out as a versatile choice due to its unique properties, which result from the chemical process of vulcanization that enhances its resilience and strength compared to non-vulcanized rubber.

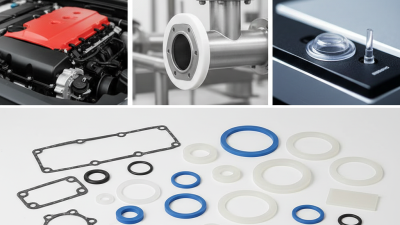

In this context, understanding the different types of vulcanized rubber available and their specific applications becomes essential for making informed decisions. Factors such as temperature stability, chemical resistance, and mechanical strength should be carefully evaluated based on the requirements of your project. Whether you are working on automotive components, industrial seals, or consumer products, selecting the appropriate vulcanized rubber can lead to enhanced performance and reduced maintenance costs, thereby adding value to your investment. In this guide, we will explore the key considerations to keep in mind while choosing the right vulcanized rubber for your needs in 2025.

Vulcanized rubber is a crucial material in various industries, known for its enhanced durability and resistance to heat, chemicals, and wear. The process of vulcanization, which involves cross-linking rubber molecules using sulfur or other agents, results in a product that exhibits improved elasticity and mechanical strength. According to a report by Grand View Research, the global vulcanized rubber market was valued at approximately $35 billion in 2022 and is expected to grow at a CAGR of around 4.5% from 2023 to 2030. This growth is driven by increasing demand in automotive, industrial, and consumer goods sectors, where performance and longevity are critical.

In terms of applications, vulcanized rubber is extensively utilized in manufacturing tires, conveyor belts, gaskets, and a wide range of seals. The automotive industry alone accounts for a significant proportion of vulcanized rubber usage, with the demand for high-performance tires increasing due to advancements in vehicle technology and safety standards. A study by Markets and Markets indicates that the automotive rubber market is set to reach $17.56 billion by 2025, reflecting the essential role that vulcanized rubber plays in enhancing vehicle performance and safety features. With such diverse applications and a growing market, understanding the specific types of vulcanized rubber suitable for varied projects is essential for engineers and manufacturers aiming to optimize their product designs.

| Property | Description | Common Applications |

|---|---|---|

| Tensile Strength | Ability to withstand pulling forces | Tires, seals, and gaskets |

| Elongation at Break | Stretchability before rupture | Safety belts, hoses |

| Hardness (Shore A) | Resistance to indentation | Footwear, flooring |

| Compression Set | Ability to return to original thickness after compression | O-rings, cushioning pads |

| Temperature Resistance | Ability to maintain properties at high or low temperatures | Automotive parts, electrical insulation |

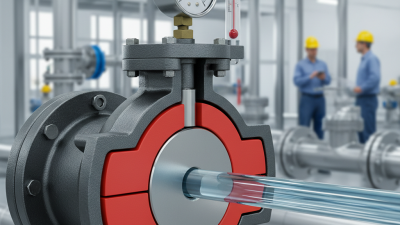

| Chemical Resistance | Resistance to deterioration when exposed to chemicals | Industrial applications, oil seals |

When selecting vulcanized rubber for your project in 2025, it's crucial to understand the key properties that contribute to its performance and suitability for specific applications. One of the primary factors to consider is the hardness or Shore durometer of the rubber. The hardness significantly affects the rubber's flexibility, resilience, and overall durability. For instance, softer rubber is often preferred for applications requiring extensive bending and stretching, while harder rubber might be chosen for load-bearing purposes.

Additionally, the tensile strength and elongation at break are vital properties to evaluate. Tensile strength measures how much force the rubber can withstand before breaking, while elongation at break indicates how much the material can stretch. High tensile strength combined with good elongation properties suggests that the vulcanized rubber will perform well under tension and resist tearing during use. Lastly, consider environmental resistance factors such as ozone resistance and temperature tolerance, which can impact the longevity of the material depending on the conditions in which it will be used. Proper consideration of these properties will help ensure that you choose the right vulcanized rubber tailored to the demands of your specific project.

When selecting the right vulcanized rubber for your project in 2025, understanding the various types of materials available is essential. Vulcanized rubber is produced through a process that enhances its durability, elasticity, and heat resistance. Among the common types, Natural Rubber, Styrene-Butadiene Rubber (SBR), and Ethylene Propylene Diene Monomer (EPDM) are frequently utilized across industries. According to a recent industry report by Grand View Research, the global demand for vulcanized rubber is projected to grow at a CAGR of 4.8% from 2025, driven largely by its applications in automotive and construction sectors.

When evaluating different types of vulcanized rubber, consider specific project requirements such as chemical resistance, temperature tolerance, and mechanical strength. For instance, EPDM exhibits outstanding resistance to heat, ozone, and weathering, making it ideal for outdoor applications. In contrast, SBR offers great wear resistance, which is crucial for applications involving high abrasion.

**Tips:**

1. Always check material specifications against your project's environmental conditions to ensure longevity and performance.

2. Consider a blend of different rubber types to achieve a balanced performance tailored to your specific application needs, optimizing costs without compromising quality.

When selecting the right vulcanized rubber for a project, several crucial factors come into play. One primary consideration is the application environment. Reports indicate that approximately 70% of rubber product failures stem from inappropriate material choices based on environmental conditions. It is essential to assess variables such as temperature, exposure to chemicals, and mechanical stress to ensure durability and performance. For instance, synthetic rubber varieties like nitrile perform exceptionally well in oil and fuel applications while EPDM is favored for its ozone and UV resistance, making it ideal for outdoor scenarios.

Another significant factor influencing the selection is the hardness and flexibility required for the project. The Shore hardness scale is widely used, with values ranging from 30A (very soft) to 90A (very hard). Data suggests that selecting the right hardness level can enhance the lifespan of the rubber product by up to 50%, depending on its intended use. Projects requiring high resilience and abrasion resistance, such as conveyor belts or automotive parts, typically benefit from harder rubber compounds. Conversely, applications that demand flexibility, like seals or gaskets, require softer compositions. By thoroughly analyzing these factors, manufacturers can optimize their material choices and ensure the success of their projects.

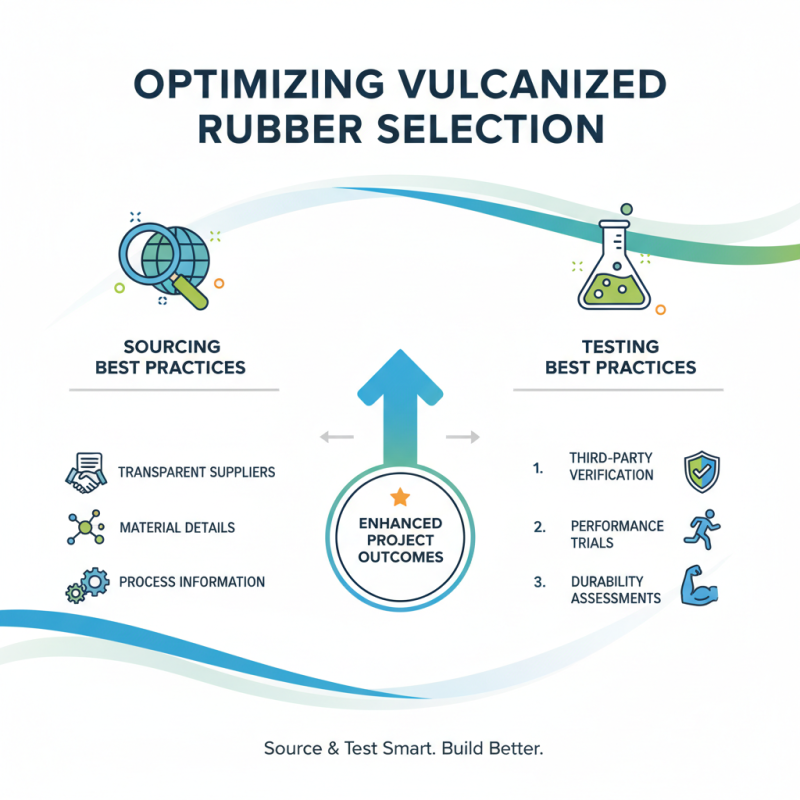

When selecting vulcanized rubber for your project, implementing best practices in sourcing and testing can significantly enhance your outcomes. Start by identifying suppliers who prioritize transparency in their processes. Engage with vendors that provide detailed information about their materials, including the types of polymers used and the specific vulcanization techniques. This transparency not only improves your understanding of the material’s properties but also helps you assess its suitability for your particular application.

Testing is another critical aspect of ensuring the quality of vulcanized rubber. Before finalizing your purchase, request sample materials to conduct preliminary tests. Examine key characteristics such as tensile strength, abrasion resistance, and thermal stability. Utilizing standardized testing methods will provide you with reliable data to compare different materials and make an informed decision. Additionally, consider the environmental factors the rubber will be exposed to, as these can influence its performance. Ensuring thorough sourcing and rigorous testing will lead to successful project outcomes while minimizing potential risks associated with material failure.