When embarking on home projects, choosing the right materials is crucial for ensuring longevity and effectiveness. Among these materials, the rubber seal stands out as a versatile solution for various applications, from windows and doors to plumbing and HVAC systems. A rubber seal not only provides an effective barrier against moisture and air leaks, but it also enhances the overall energy efficiency of your home. However, with numerous types of rubber seals available, understanding how to select the appropriate one for your specific needs can be daunting.

In this guide, we will explore the essential factors to consider when choosing a rubber seal. Different projects may require distinct properties such as resistance to temperature fluctuations, UV degradation, or chemical exposure. Furthermore, the size and shape of the rubber seal play a critical role in its performance. By identifying the right type and understanding its specifications, homeowners can effectively prevent costly repairs and maintain a comfortable living environment. Whether you are sealing drafty windows or preventing leakages in plumbing, making an informed decision about your rubber seal will ensure that your home projects are successful and sustainable.

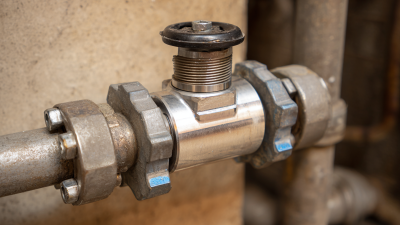

When embarking on home projects that require sealing solutions, it's crucial to understand the different types of rubber seals available, as each type serves specific purposes and environments. One common type is the O-ring, a circular sealing component typically used in plumbing and automotive applications. O-rings are valued for their flexibility, durability, and ability to withstand high pressure and a variety of temperatures, making them suitable for sealing connections in pipes and hydraulic systems.

Another popular option is the flat rubber gasket, which offers a larger surface area for sealing compared to O-rings. Flat gaskets are often used in applications such as automotive engine components and household appliances. They can effectively fill the gap between two surfaces, preventing leakage of fluids or gases. Additionally, there are foam rubber seals, which provide excellent insulation and cushioning, making them ideal for doors and windows to enhance energy efficiency. Each type of rubber seal comes with its own set of characteristics, so selecting the right one is essential for ensuring effective sealing in your home projects.

When evaluating the specific requirements of your home project, selecting the right rubber seal is crucial to ensure optimal performance and longevity. Different projects will have varied needs based on factors such as temperature fluctuations, exposure to chemicals, and the environment. According to recent studies in the construction and home improvement sector, approximately 30% of water damage in homes can be attributed to inadequate sealing. This highlights the importance of a well-chosen rubber seal, which can mitigate such risks effectively.

Firstly, the physical properties of rubber seals, including hardness and flexibility, play a vital role in their application. For instance, seals used in external windows must withstand harsh weather conditions, making them more effective when they have a durometer hardness rating of around 65A to 75A. Additionally, understanding the specific chemical exposure in your project is essential. Research indicates that seals made from EPDM rubber can resist ozone and UV degradation, making them suitable for outdoor use, while silicone seals might be better for high-temperature applications.

Moreover, the dimensions and fitting of the rubber seal are significant considerations. A comprehensive analysis of sealing systems in residential settings found that properly sized seals can reduce air leakage by up to 25%, contributing to energy efficiency. Measuring the gaps accurately and selecting the correct profile type—whether flat, oval, or square—is vital for ensuring a tight fit. By aligning the selection of rubber seals with the unique demands of your home projects, you can enhance both protection and efficiency in your living environment.

This chart illustrates the common types of rubber seals used in home projects and their suitability based on specific applications such as doors, windows, and plumbing. The data reflects the relative effectiveness of each type in sealing capabilities.

When selecting the right rubber seal for your home projects, it’s crucial to consider the environmental conditions in which the seal will perform. Factors such as temperature, humidity, and exposure to chemicals will influence the effectiveness and longevity of the seal. For instance, if you are sealing areas prone to moisture, like bathrooms or kitchens, opt for seals that are resistant to water and mold growth. Conversely, for exterior applications exposed to varying temperatures, choose rubber seals that maintain flexibility in extreme conditions.

Tips: Always test the sealant in a small area before applying it extensively. This ensures compatibility with your surfaces and gives you a preview of its performance under real conditions.

Additionally, consider UV stability if the rubber seal will be placed outdoors. Seals that are not UV resistant can degrade quickly when exposed to sunlight, resulting in costly repairs over time. Utilizing seals with added UV inhibitors can significantly enhance durability.

Tips: Look for seals that have been specifically rated for outdoor use, and check product specifications for UV resistance to prolong their lifespan.

When applying rubber seals for home projects, installation considerations play a critical role in ensuring effectiveness and longevity. First and foremost, it is vital to assess the specific area where the seal will be applied. Cleanliness is key; any debris, dust, or old adhesive must be removed to create a suitable surface for the seal to adhere to. Evaluating the surface texture—whether it is smooth, rough, or uneven—will also help in selecting the right type of seal that can accommodate those conditions.

Another significant factor during installation is temperature and humidity. Rubber seals can expand or contract depending on environmental conditions, which can affect their integrity. Ideally, installation should occur when temperatures are stable and within the recommended range for the type of sealing material being used. Additionally, applying the seal under ideal humidity levels can enhance adhesion and prevent moisture intrusion. Finally, taking into account the proper amount of sealant and ensuring even application can prevent future leaks or failures, making the project more robust and efficient.

Maintaining and replacing rubber seals is crucial for ensuring the longevity and performance of your home projects. Rubber seals are used in a variety of applications, from windows and doors to plumbing and HVAC systems. According to the American Society of Mechanical Engineers (ASME), regular inspection and maintenance can extend the lifespan of rubber seals significantly, often by as much as 40%. This is primarily due to the prevention of wear and tear caused by environmental factors such as UV exposure, temperature fluctuations, and moisture.

When it comes to replacement, it's essential to select seals made from the right materials to ensure durability and effectiveness. Reports from the Rubber Manufacturers Association (RMA) indicate that synthetic rubber compounds can outperform traditional natural rubber for many home applications, particularly in extreme weather conditions. Choosing the correct seal type can also greatly reduce energy costs—studies show that properly sealed windows and doors can decrease energy consumption by up to 15%, leading to significant savings over time. Understanding the properties of different rubber materials and their suitability for various environments will go a long way in maintaining your home’s efficiency and comfort.