When selecting materials for various projects, the significance of choosing the right type of silicone rubber cannot be overstated. According to a recent market analysis by Research and Markets, the global silicone rubber market is expected to reach USD 9.89 billion by 2026, growing at a CAGR of 4.5% from 2021 to 2026. This growth is primarily driven by the increasing demand for silicone rubber in automotive, healthcare, and consumer goods applications. The versatile properties of silicone rubber, including its heat resistance, flexibility, and chemical stability, make it an ideal choice for a wide range of industrial and consumer applications.

In addition, a report by Grand View Research highlights that the automotive segment is projected to dominate the silicone rubber market, attributing this trend to the increasing use of silicone in electronic components, seals, and gaskets. When embarking on a project, understanding the specific requirements, such as temperature tolerance, mechanical strength, and resistance to environmental factors, is crucial. The right selection from the myriad types of silicone rubber available can significantly impact the performance, durability, and overall success of a project. Thus, it becomes essential for professionals to evaluate their project needs thoroughly before making a choice, ensuring that they opt for a silicone rubber variant that is best suited to their requirements.

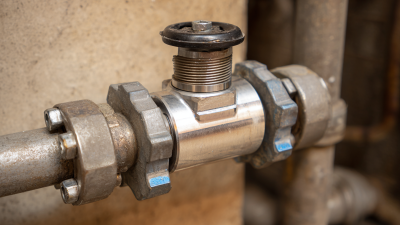

When selecting silicone rubber for your project, several key factors come into play that can significantly impact the performance and durability of the finished product. First, consider the specific properties of silicone rubber, such as temperature resistance, flexibility, and resistance to chemicals. According to a report by the Silicone Alliance, silicone can maintain its flexibility over a temperature range from -60°F to 400°F, making it ideal for applications that experience extreme temperatures.

Another critical factor is the application type. For instance, if the silicone rubber is intended for use in medical devices, it is essential to select materials that meet stringent biocompatibility standards. The FDA provides guidelines on silicone formulations used in medical applications, which must be adhered to for safety and compliance.

**Tips:** Always consult the technical data sheets provided by suppliers to assess properties such as durometer, tensile strength, and elongation at break. These specifications will help determine if a silicone rubber meets your performance requirements. Additionally, testing small samples under real-life conditions can provide insights into the silicone's long-term performance in your specific application.

When selecting the best silicone rubber for your project, it's crucial to understand the various types and their applications across different industries. Silicone rubber can be categorized into types like elastomers, fluids, resins, and gels, each serving distinct roles in sectors such as building and construction, automotive, and healthcare. For instance, silicone elastomers are widely used in applications requiring flexibility and resilience, while silicone fluids are favored in applications demanding excellent thermal stability.

According to the latest market analysis, the silicone market is projected to reach USD 33,246.3 million by 2030, indicating robust growth driven by increasing demand in diverse end-use industries. Silicone gasket-free sealants, with a forecasted market of USD 110.3 million by 2035, exemplify this trend, showing an impressive CAGR of 3.1% between 2025 and 2035. This data underscores the growing reliance on silicone materials, highlighting their versatility and durability.

**Tips:** When choosing silicone rubber, consider the specific requirements of your application, such as temperature resistance and environmental conditions. Always consult detailed industry reports to stay informed about market trends and product innovations that can enhance your project efficiency. Additionally, ensure that the silicone type selected aligns with regulatory standards pertinent to your industry's needs.

| Type of Silicone Rubber | Properties | Applications | Industry |

|---|---|---|---|

| High-Temperature Silicone | Excellent thermal stability, maintains flexibility at high temperatures | Gaskets, seals, and bonding applications | Aerospace, automotive |

| Medical-Grade Silicone | Biocompatible, non-toxic, high purity | Implants, medical devices, tubing | Healthcare, pharmaceuticals |

| Food-Grade Silicone | Non-toxic, odorless, easy to clean | Baking mats, molds, kitchenware | Food and beverage |

| Electrical Insulating Silicone | High dielectric strength, resistant to electrical discharge | Insulating components, potting applications | Electronics, telecommunications |

| Flame Retardant Silicone | Reduces flammability, self-extinguishing properties | Fireproof seals, cables, coatings | Construction, automotive |

When selecting silicone rubber for specific projects, durability and performance characteristics are paramount. The best silicone materials not only withstand extreme temperatures but also maintain their flexibility and elasticity over time. Features such as resistance to UV radiation, moisture, and chemicals can significantly enhance the longevity of the product, making them suitable for a wide range of applications, from automotive components to medical devices. For instance, innovative formulations of silicone rubber are now being developed to exhibit enhanced fire performance, further catering to safety requirements in industrial contexts.

Additionally, advancements in silicone technology are leading to the emergence of specialized materials that address specific needs, such as biocompatibility and electroconductivity for healthcare devices. Products that incorporate high-consistency silicone rubber are being showcased for their robustness and versatility, signaling a trend towards more tailored solutions in various sectors including textiles, electronics, and construction. As industries continue to innovate, understanding these durability and performance characteristics will empower businesses to choose the right silicone rubber that meets their project requirements effectively.

When selecting silicone rubber for your projects, cost-effectiveness plays a crucial role in ensuring that you achieve a balance between quality and budget. According to industry data, high-quality silicone rubber can range significantly in price, with premium options costing up to 30% more than standard grades. However, investing in better quality materials often leads to enhanced performance and durability, potentially lowering long-term costs associated with repairs and replacements.

For example, an analysis from a leading materials research firm indicates that projects using high-grade silicone rubber have a failure rate of less than 5% compared to 15% for lower-grade alternatives. Therefore, while the upfront cost of top-tier silicone may deter some buyers, the resulting lifespan and functionality can justify the expense. By carefully evaluating project specifications and considering the benefits of premium silicone, you can make more informed purchasing decisions that align with your budget, ultimately leading to greater satisfaction with your project outcomes.

This chart illustrates the cost per kilogram of various types of silicone rubber. Balancing quality and budget is essential when selecting the right silicone rubber for your project, as different types offer varying costs and applications.

As industries continue to innovate, the future of silicone rubber is set to transform significantly by 2025 and beyond. Reports from the Global Silicone Market indicate that the demand for silicone rubber is projected to surpass $10 billion, driven by advancements in automotive and electronics sectors. Innovations in chemical formulations and processing techniques will enhance performance characteristics, making silicone rubber more versatile, resilient, and environmentally friendly.

Tips: When selecting silicone rubber, consider the specific requirements of your project, including temperature resistance and chemical compatibility. Collaborating closely with suppliers can lead to discovering custom formulations tailored to unique applications.

Moreover, the emergence of sustainable silicone alternatives is gaining traction. With growing awareness of environmental concerns, manufacturers are investing in bio-based silicones that maintain performance while reducing ecological impact. This trend is corroborated by the 2021 Market Research report, which predicts a 15% CAGR for eco-friendly silicone products over the next five years.

Tips: Evaluate the lifecycle of silicone materials when making your choice. Prioritizing sustainable options not only aligns with corporate responsibility goals but can also appeal to environmentally conscious consumers.