A Center Line Valve is a crucial component in various piping systems. It operates with a simple yet effective mechanism. Understanding how it works can enhance efficiency and safety in industrial applications.

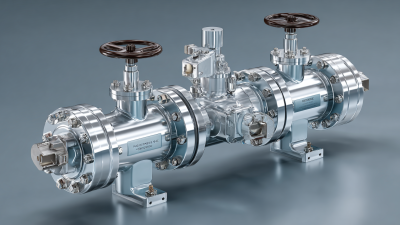

This valve features a unique design where the valve seat is centered on the pipe's centerline. This design minimizes pressure drops and maximizes flow rates. The Center Line Valve can handle different fluids, making it versatile in many settings. Users often appreciate its reliability and ease of maintenance.

However, relying strictly on the Center Line Valve may lead to oversight in specific applications. Maintenance schedules could be neglected. Users might overlook regular inspection protocols, which could cause performance issues. It is vital to remain vigilant and evaluate the valve's condition frequently. This approach ensures it functions optimally in critical systems.

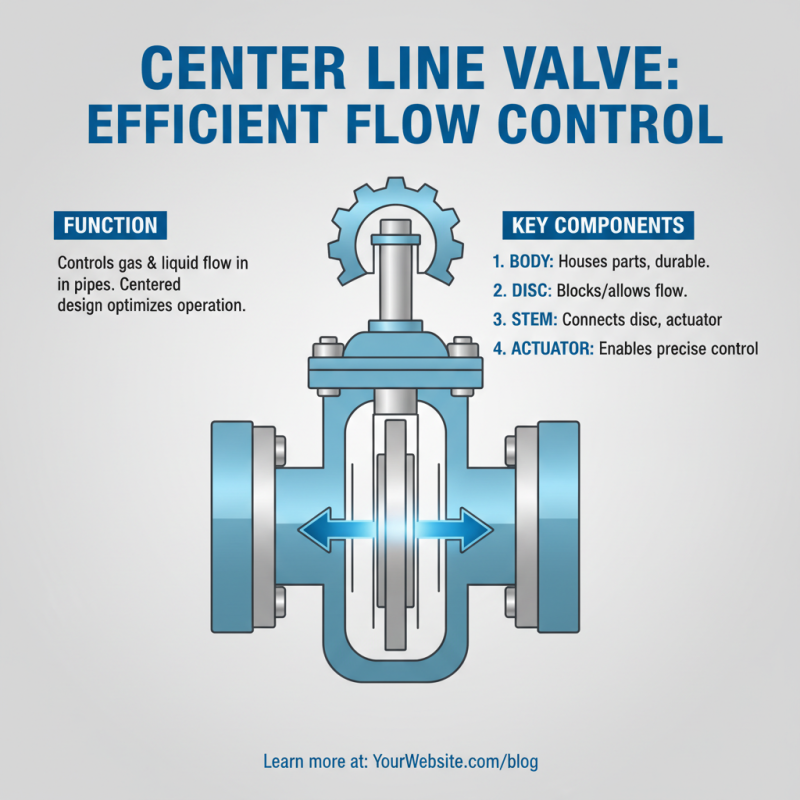

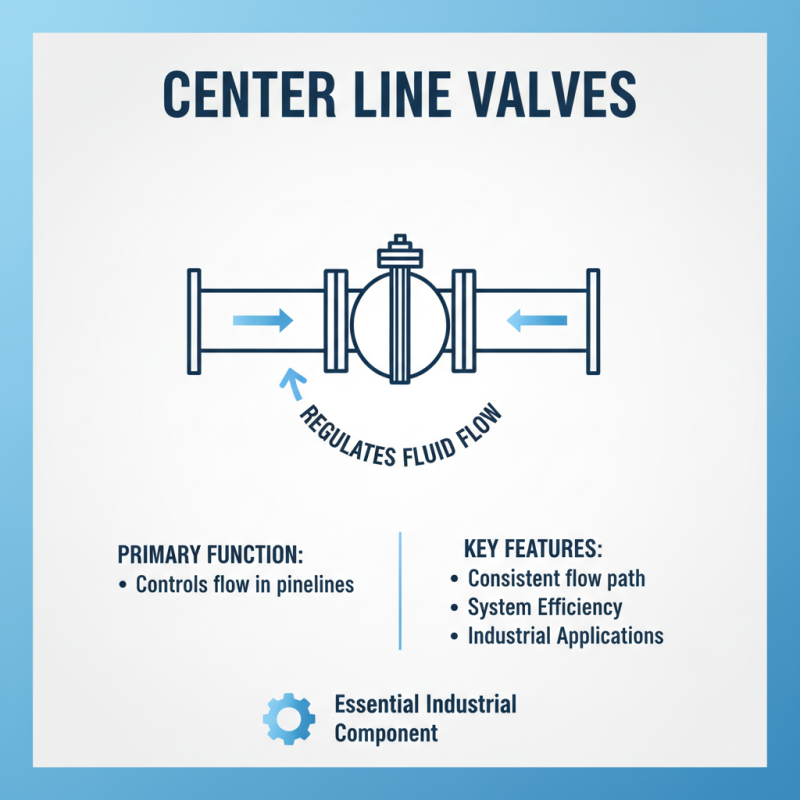

A center line valve is a specialized device used to control the flow of gases and liquids in pipes. Its design centers the flow path, allowing for efficient operation. The primary components include the body, disc, stem, and actuator. The body houses all parts, ensuring durability against pressure. The disc is crucial; it can block or allow flow. The stem connects the disc to the actuator, enabling precise control.

The actuator is integral to the valve’s functionality. It can be manual or automatic. This versatility allows operators to adjust flow levels easily. During operation, the sealing mechanism is important. It minimizes leaks and ensures safety. However, issues may arise if components wear over time. Regular maintenance is often overlooked but necessary.

Understanding these components is crucial for system efficiency. Many operators forget to check the actuator regularly. This can lead to unexpected failures. Observing how each part interacts helps predict potential problems. Without such reflections, maintaining flow becomes a challenge. Each component plays an essential role in the overall function of a center line valve.

Center line valves are essential components in various industrial applications. Their primary function involves regulating the flow of fluids in pipelines. The valve's design allows it to maintain a consistent flow path, which is critical for system efficiency.

The principle of operation for center line valves hinges on a central axis mechanism. This mechanism allows the valve's disc to rotate, opening or closing the flow path. According to industry reports, these valves can significantly reduce pressure drops, which is crucial for energy efficiency. In fact, studies indicate that proper valve selection can lead to energy savings of up to 15%.

However, the operation of center line valves is not without challenges. Wear and tear can affect performance over time. Regular maintenance is necessary to ensure longevity. Neglecting this can lead to leaks or system failures. Data shows that nearly 30% of valve-related issues stem from inadequate upkeep. Ensuring that these valves operate smoothly is vital for process integrity and safety, making awareness and proactive measures essential in industrial settings.

Center line valves are essential components in various industries. These valves facilitate the control of fluid flow. Their unique design allows for efficient operation. Different types of center line valves serve specific functions.

Ball valves are one popular type. They provide a tight seal and quick shut-off. These valves are often used in water supply systems.

Butterfly valves, on the other hand, allow for easy flow regulation. They are common in HVAC applications.

Check valves prevent backflow, ensuring systems operate smoothly. Each valve type has its own strengths and weaknesses.

While center line valves offer great advantages, improper use can lead to failures. Choosing the right type for the application is crucial. Overlooking maintenance can also cause issues. Regular inspection is necessary to ensure longevity. Understanding these nuances can improve system efficiency.

Center line valves have gained traction across various industries due to their unique design and operational benefits. These valves feature a simple structure that minimizes turbulence, which enhances flow efficiency. According to industry reports, these valves can improve flow rates by up to 30%. This is crucial in sectors like oil and gas, where every percentage point can mean significant cost savings.

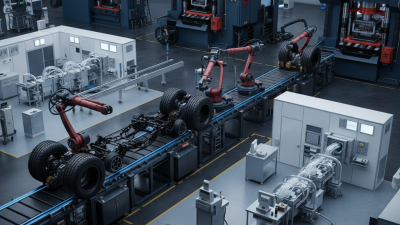

In manufacturing, the versatility of center line valves plays a pivotal role. They are suitable for high-pressure applications, making them essential in chemical processing. A study by an industry association indicates that using center line valves can reduce maintenance costs by approximately 20%. Reliable performance reduces downtime, an important factor for productivity in a competitive market.

However, installation and maintenance can still pose challenges. Proper alignment is crucial to avoid leaks, and errors can lead to costly repairs. Training staff on best practices is necessary. Some companies report having to repeat installations due to improper handling, emphasizing the need for continuous improvement in operational procedures. Adopting center line valves can yield excellent results, but their full potential is only realized with thorough understanding and adherence to guidelines.

Center line valves are critical components in many industrial applications. They control the flow of liquids and gases. Regular maintenance is essential to ensure their reliability. Without proper care, these valves can malfunction, leading to costly downtime.

Maintenance tasks include regular inspections. Check for leaks, corrosion, and wear. Lubricate moving parts to maintain smooth operation. Ignoring these tasks can result in reduced efficiency. Operators should follow a consistent schedule. It’s easy to forget maintenance amid busy schedules. This can lead to unexpected failures.

Troubleshooting involves identifying issues quickly. If a valve fails to open or close, inspect the actuator. Check for blockages in the piping system. Often, simple adjustments can resolve the problem. However, it's crucial to understand that not all issues are straightforward. Sometimes, deeper problems exist that require professional insight. A reflective approach to valve management helps prevent future issues.