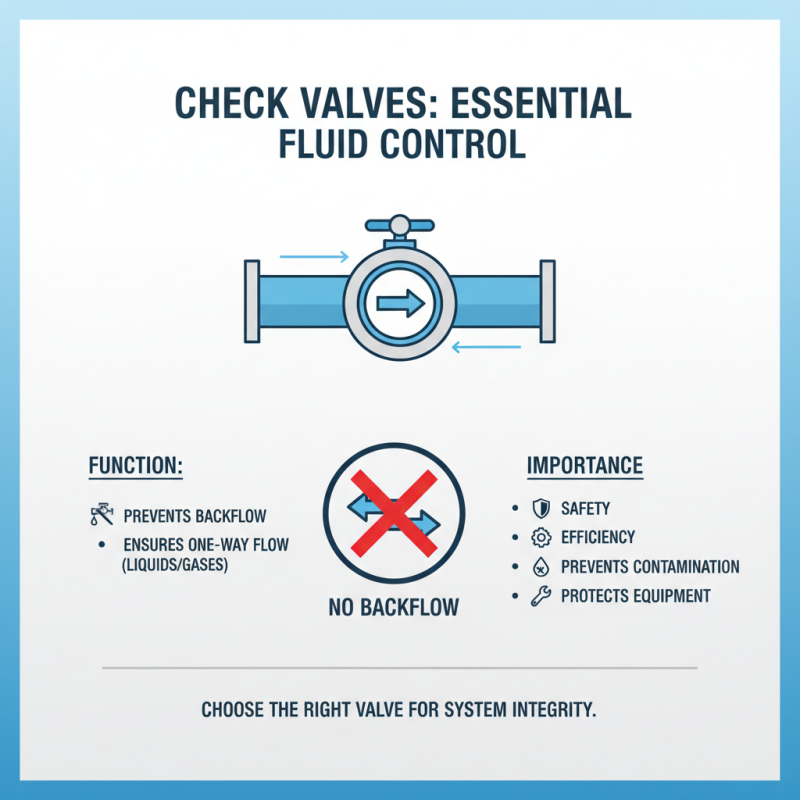

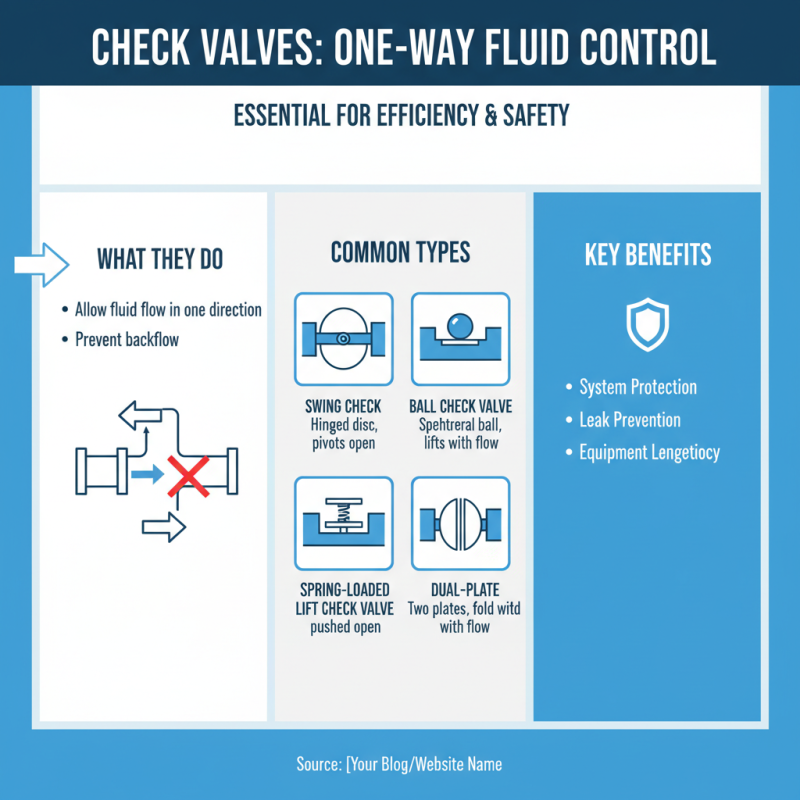

Choosing the right check valve for your systems requires careful consideration. Check valves play a critical role in ensuring fluid flows in one direction while preventing backflow. Understanding various types of check valves can help you select the best fit for your needs.

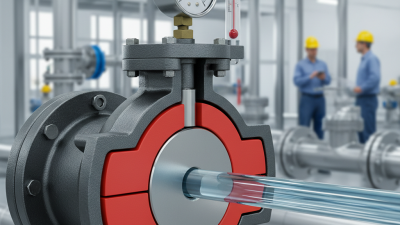

There are different designs, including ball, swing, and lift check valves. Each type has unique advantages and applications. For example, ball check valves are excellent for low-pressure systems, while swing check valves work well in larger pipelines. The right check valve can enhance system efficiency, but improper selection can lead to issues.

Reflecting on your specific system requirements is essential. Consider factors such as pressure, temperature, and fluid type. Selecting a check valve seems straightforward, but getting it wrong can cause headaches. It's worth looking deeper into the options available and any potential limitations. Check valves are vital, yet they are often overlooked until problems arise.

Check valves play a crucial role in fluid systems. They prevent backflow, ensuring one-way flow of liquids or gases. In many applications, this function is essential for safety and efficiency. If a system allows backflow, it can cause serious issues, like mixing of fluids. This can lead to contamination or equipment damage, so choosing the right check valve is vital.

When selecting a check valve, consider the flow direction and pressure requirements. Not all check valves work well in every situation. For instance, a swing check valve may be ideal for low-pressure systems, while a lift check valve offers better performance under higher pressures. Always evaluate your specific needs to choose wisely.

Tips for effective check valve use: Regular maintenance is key. Inspect your check valves for wear or damage periodically. Clean them to remove debris that can hinder operation. Also, ensure they are installed correctly. An improper installation can lead to system inefficiencies. Checking these details could save time and costs later on.

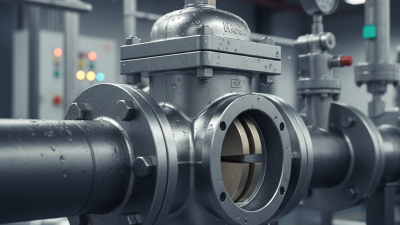

Check valves are essential in many systems. They ensure that fluid flows in one direction, preventing backflow. There are several common types, each suited for specific applications. Understanding these can enhance efficiency and safety.

In wastewater systems, swing check valves are frequently used. They can handle larger volumes but may require more space. A 2021 industry report noted that these valves represent about 30% of the market. Their simplicity is appealing, but they may not seal perfectly under low pressure. This could lead to inefficiencies.

In contrast, spring-loaded check valves are compact. They provide reliable sealing in tight spaces. Their mechanism allows quick closure, which is vital in high-speed applications. However, they may wear out faster due to constant movement. Recent findings suggest that about 25% of leaks in systems come from faulty check valves. Operators need to assess the right type for their specific needs constantly.

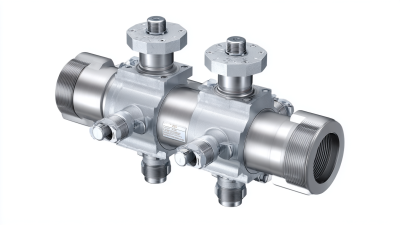

When selecting a check valve, several factors come into play. The flow direction is crucial. A single-directional flow ensures optimal performance. In fact, industry studies report that misaligned valves can lead to a 30% efficiency loss. For systems with fluctuating pressure, a spring-loaded check valve might be ideal. However, these can wear out faster than expected.

Material choice is another key factor. Common materials include stainless steel, brass, and PVC. A recent report highlighted that 40% of valve failures are linked to material degradation. Depending on the medium you’re dealing with, the wrong material can lead to leaks or blockages. Lastly, consider your system's pressure rating. An under- or over-rated valve can result in catastrophic failures. What might seem like a small oversight during selection can escalate into costly repairs.

Check valves are essential in many systems. They prevent backflow and protect equipment. However, different types carry their own strengths and weaknesses.

Ball check valves are common. They offer a tight seal and are easy to maintain. They perform well in low-pressure systems, but can clog with debris. This limits their effectiveness. According to industry reports, the failure rate in dirty environments can reach up to 30%.

Spring check valves are another option. They react quickly, closing tightly when flow reverses. This ensures system safety. However, they can wear out faster due to constant spring tension. Studies show that improper installation can lead to a 20% increase in failure rates. It’s crucial to assess these factors before selection.

When it comes to check valves, maintenance and installation are key to their longevity. Regular inspections can prevent unforeseen issues. Check for signs of wear, such as leaks, corrosion, or irregular sounds. These can indicate that it’s time for repairs or replacement.

Installation plays a critical role in valve performance. Ensure they are correctly oriented in the system. Incorrect alignment can lead to pressure loss or valve failure. Use the right tools for the job. Tighten fittings securely, but avoid over-tightening. This can damage the valve or the surrounding pipes.

Tips for success: Always refer to technical guidelines for proper specifications. Never skip routine maintenance checks. A small oversight can lead to larger system failures. If in doubt, consult a professional. This may save time and expense in the long run.