In the intricate landscape of industrial applications, the importance of selecting the right valve type cannot be overstated. Center Line Valves, known for their balanced design and efficient flow control, have emerged as a preferred choice among engineers and industry professionals. According to Dr. James R. Thornton, a renowned expert in fluid dynamics, "When it comes to optimizing system performance, the choice of a Center Line Valve can dramatically influence both efficiency and reliability." This statement underscores the significance of this valve type in achieving optimal performance across various industrial scenarios.

As industries increasingly prioritize efficiency and operational excellence, understanding the nuances of Center Line Valves becomes essential. These valves offer unique benefits, such as reduced torque requirements and better sealing capabilities, making them ideal for demanding applications. In this article, we will explore the ten best Center Line Valves specifically designed to meet the stringent requirements of industrial environments, providing insights into their features, advantages, and optimal use cases. By delving into the key characteristics and performance aspects, we aim to equip professionals with the knowledge needed to make informed decisions for their specific applications.

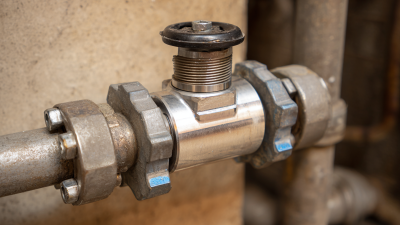

When selecting center line valves for industrial applications, several key factors significantly influence their performance. One of the most critical aspects is the design of the valve itself. A well-engineered valve will facilitate smoother flow, reducing pressure drops and minimizing turbulence. This is essential in applications where maintaining precise flow rates and pressure levels is vital for operational efficiency. Additionally, the material used in valve construction plays a pivotal role in durability and resistance to corrosion, especially in harsh industrial environments.

When selecting center line valves for industrial applications, several key factors significantly influence their performance. One of the most critical aspects is the design of the valve itself. A well-engineered valve will facilitate smoother flow, reducing pressure drops and minimizing turbulence. This is essential in applications where maintaining precise flow rates and pressure levels is vital for operational efficiency. Additionally, the material used in valve construction plays a pivotal role in durability and resistance to corrosion, especially in harsh industrial environments.

Another important factor is the actuation method. Center line valves can be manually operated, electrically actuated, or pneumatic, and the choice depends on the specific requirements of the application. Automated systems often enhance response times and precision, but they must be matched to the operational conditions to avoid failures. Furthermore, regular maintenance and monitoring of the valve’s performance can prevent unexpected downtime and costly repairs. Overall, attention to these factors can significantly enhance the effectiveness and longevity of center line valves in industrial settings.

When selecting center line valves for optimal efficiency in industrial applications, several key specifications should be considered to ensure peak performance. One of the most crucial aspects is the valve's material. According to a recent industry report by MarketsandMarkets, the demand for corrosion-resistant materials in valve manufacturing is projected to grow substantially, driven by the need for durability in harsh environments. Materials such as stainless steel and alloys are favored for their strength and resistance to degradation, which are vital for maintaining operational integrity over time.

Another important specification is the valve's connection type. The flexibility of installation can have significant operational implications, especially in complex piping systems. As highlighted by a study from Research and Markets, valves that offer multiple connection options can enhance system efficiency by simplifying integration and reducing failure points. Additionally, the valve's flow characteristics, including Cv (flow coefficient), play a pivotal role in determining how effectively it can manage fluids under varying pressure conditions, which is critical for processes that require precise flow control. Understanding these parameters can dramatically impact both the performance and longevity of industrial applications.

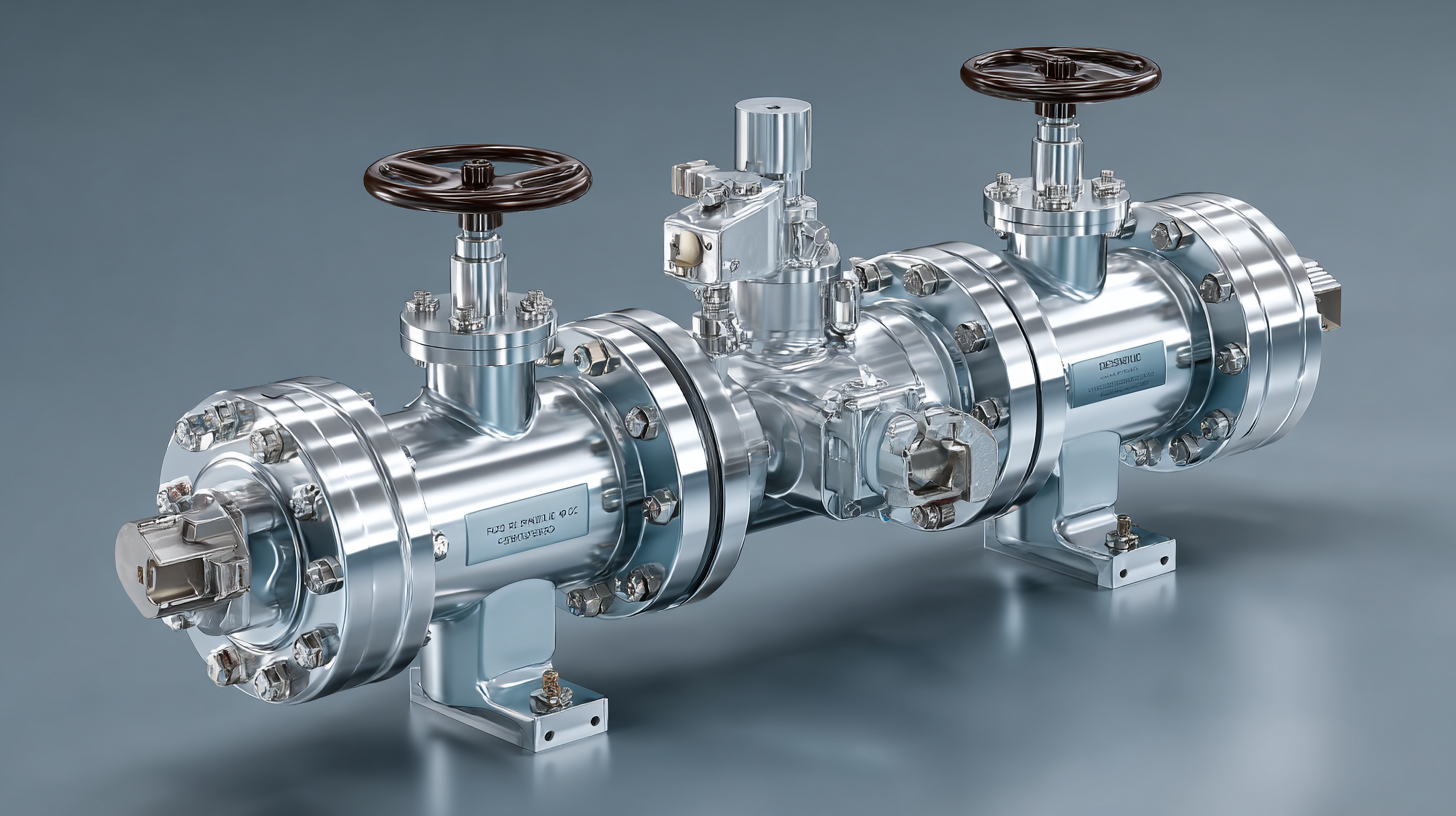

In the realm of industrial applications, center line valves play a crucial role in ensuring optimal performance across various processes. A comparative analysis of leading center line valve brands reveals significant differences in their design, functionality, and suitability for specific operational requirements. These valves are primarily distinguished by their ability to facilitate efficient flow control while minimizing pressure drops, which is essential in maintaining system integrity and energy efficiency.

As industries pivot towards cleaner energy solutions, the evolution of valve technology, particularly in the hydrogen sector, is becoming increasingly important. Manufacturers are focusing on innovations that enhance the reliability and performance of center line valves, especially for applications involving hydrogen gas, where safety and operational efficiency are paramount. The competitive landscape is shifting, with emerging technologies promising to improve valve designs, thus supporting the ongoing transition to sustainable energy sources. This trend underscores the importance of choosing the right valve system that not only meets current demands but also aligns with future industry standards.

The durability of center line valves in harsh environments is significantly influenced by their material composition. Valves operate under a range of pressures and temperatures, often in corrosive or abrasive settings. Materials such as stainless steel, bronze, and specialized alloys are commonly employed to enhance resilience. Stainless steel, for instance, offers excellent corrosion resistance and can withstand high temperatures, making it ideal for chemical processing industries. In contrast, bronze valves are favored for applications involving water and oil due to their superior strength and ability to fight corrosion, although they may not hold up as well under extreme temperature fluctuations.

Furthermore, the choice of materials impacts not only longevity but also operational efficiency. Valves constructed from inferior materials may degrade quickly, leading to leaks or system failures that can compromise safety and performance. Companies must prioritize material selection during the design phase to ensure that the valves can endure specific environmental challenges, such as exposure to extreme temperatures, corrosive chemicals, or mechanical wear. Ultimately, understanding the relationship between material composition and valve durability is crucial for optimizing performance and reducing maintenance costs in industrial applications.

Recent innovations in center line valve technology have significantly enhanced their efficiency and reliability in various industrial applications. Advancements in materials and manufacturing processes have led to valves that withstand higher pressures and temperatures while minimizing leakage and wear. The integration of smart technology has also transformed traditional valves into intelligent systems capable of real-time monitoring and predictive maintenance, thereby reducing downtime and operational costs.

Moreover, the application of these advanced center line valves spans across numerous industries, including chemical, oil and gas, and water treatment. Their design allows for seamless integration into existing systems, making them a preferred choice for engineers seeking to upgrade operational performance. These innovations not only enhance flow control and optimize process efficiency but also contribute to improving safety standards through better leak detection and environmental protection measures. The evolution of center line valve technology is paving the way for more sustainable and efficient industrial practices.