When it comes to choosing the best butterfly valve for your needs, expert insights can make a difference. David Walker, a renowned valve industry expert, once said, "The right butterfly valve can enhance system performance significantly." In the world of fluid control, butterfly valves stand out for their efficiency and space-saving design.

Selecting the ideal butterfly valve can be overwhelming. There are various types and materials to consider. Some choices may not fit every application, leading to potential issues. Attention to detail is crucial. For example, the wrong size can cause leaks or pressure loss. The right balance between quality and cost is essential.

Exploring options helps navigate this complexity. We’ve compiled a list of the best butterfly valve options to suit different needs. Each selection considers various factors, such as durability and performance. These insights can guide you toward an informed decision for your next project. Choosing wisely will reflect in your system's efficiency.

Butterfly valves are essential components in fluid control systems. They have a simple structure that allows for quick operation and reliable performance. Typically, these valves regulate the flow of liquids and gases. They achieve this by rotating a disc within the valve body, which either opens or closes the flow path. This design makes them a popular choice across various industries.

Tips: When selecting a butterfly valve, consider the fluid type. Corrosive liquids may require specific materials for durability. Ensure compatibility to avoid premature wear or failure.

The functionality of a butterfly valve lies in its ease of use. Their compact size allows for installation in tight spaces. However, improper installation may lead to leaks or inefficiencies. Regular maintenance checks are crucial. This prevents issues and ensures the valve operates smoothly over time.

Tips: Always verify the sizing and specs before purchase. A poorly sized valve can negatively impact system performance. Calibration may be necessary to achieve optimal results.

Choosing the right butterfly valve involves several critical factors. The first consideration is the material. Different environments require various materials. For instance, stainless steel is robust in many applications. However, it can be pricey. Plastic valves may suit less demanding conditions but might wear out quicker.

Next, think about the seat design. The seat affects sealing performance. A resilient seat can handle higher pressures. Soft seats usually offer better sealing but can degrade under certain conditions. Balance the need for durability and sealing efficiency.

Tips: Always consider the valve's pressure rating. This impacts its suitability for your application. Check installation space too; improper fits lead to leaks or damage. Lastly, reflect on maintenance needs. Some valves require frequent checks, while others are more self-sufficient. Choose wisely based on your operational demands.

When selecting a butterfly valve, features and benefits are crucial. These valves are essential in controlling the flow of liquids and gases. According to industry reports, butterfly valves account for about 20% of the valve market due to their efficiency. Their lightweight design allows for quick opening and closing, making them ideal for high-flow applications.

Cheaper options might lack durability, leading to failures. This drawback can compromise operation and safety. Some models feature a resilient seat design, offering better sealing performance and a longer lifespan. Additionally, valves with ISO flanges can enhance compatibility with existing systems. For regular maintenance, consider using valves with easy-access designs. This can save you time and money.

Tips: Always check the materials used in the valve's construction. Corrosion-resistant materials are vital in harsh environments. Remember that not all butterfly valves are created equal; flow rates can vary significantly. A mismatch can lead to inefficiencies. Be sure to evaluate your specific application needs before making a decision.

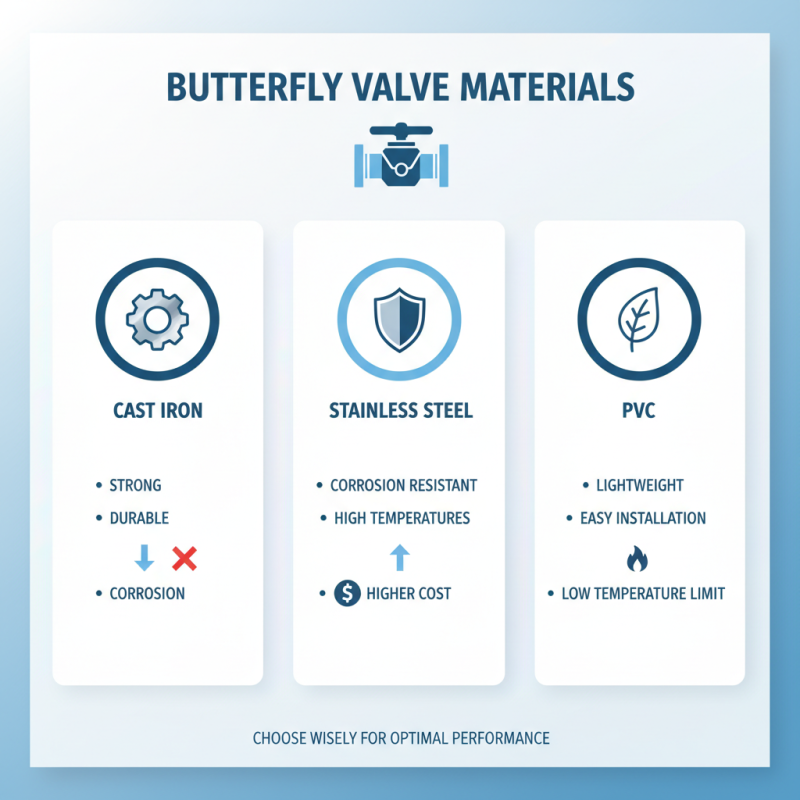

When it comes to butterfly valves, material selection is crucial. Various materials impact durability and performance. Common options include cast iron, stainless steel, and PVC. Each material offers unique attributes. For example, cast iron is strong but may corrode. Stainless steel resists rust but is often more expensive. PVC is lightweight, making it easy to install, but it may not handle high temperatures well.

According to industry reports, stainless steel valves are prevalent in water treatment plants. Their corrosion resistance ensures a longer lifespan. However, an analysis revealed that nearly 30% of users experienced issues with premature wear. This highlights the need for proper selection based on application.

Tip: Always consider the environment before choosing a material. High-pressure systems may need robust options.

PVC valves are popular in agricultural settings. They're affordable and light. But remember, extreme weather can cause brittleness. Check the manufacturer's specifications to avoid failures.

Tip: Conduct regular inspections to identify wear early. This can save costs in the long run. The right material, matched with appropriate maintenance, can enhance performance and longevity.

Proper maintenance of butterfly valves is crucial for longevity. Regular inspections can help identify issues early. Research shows that valves that are routinely checked every six months can last up to 20% longer than those that are neglected. This can save significant costs in replacements and downtime.

Lubrication is essential. Many experts recommend using non-petroleum-based lubricants. This prevents the buildup of harmful residues. Valves in corrosive environments require special attention. The coating should be inspected regularly for wear. Data indicates that 30% of valve failures are due to coating deterioration.

Keep an eye on the actuator. Tightening loose connections can prevent malfunctions. Some users overlook this simple step. But as a result, they face unexpected failures. Training personnel on valve operation is vital. Lack of knowledge can lead to improper handling. In fact, studies show that improper use increases wear and tear by nearly 40%. Make sure your team knows what they're doing.

| Valve Size (inches) | Material | Pressure Rating (PSI) | Temperature Range (°F) | Applications |

|---|---|---|---|---|

| 2 | Cast Iron | 150 | -20 to 250 | Water, Oil |

| 4 | Stainless Steel | 300 | -20 to 400 | Chemical Processing |

| 6 | PVC | 150 | -10 to 140 | Water Treatment |

| 8 | Ductile Iron | 200 | -20 to 300 | Oil & Gas |

| 10 | Aluminum | 150 | -40 to 200 | Pharmaceuticals |