In the dynamic landscape of manufacturing, the choice of materials and processes can significantly impact the overall efficiency and product quality. One method that has gained considerable attention is rubber molding, a versatile manufacturing technique that offers numerous advantages across various industries. According to John Smith, a leading expert in the rubber manufacturing sector, “Rubber molding is not just a manufacturing process; it is a pathway to innovation and efficiency.”

Rubber molding enables manufacturers to create complex shapes and designs with precision, providing solutions that meet the specific demands of their projects. This method is particularly beneficial due to its ability to produce high-quality, durable products at a lower cost compared to traditional methods. Additionally, the scalability of rubber molding allows for both small-scale prototypes and large-volume production runs, making it an ideal choice for businesses looking to optimize their manufacturing processes. As the industry evolves, understanding the top benefits of rubber molding becomes essential for manufacturers seeking competitive advantages in today’s marketplace.

Rubber molding has emerged as a critical process in various manufacturing sectors, delivering unique advantages that enhance overall production efficiency and product quality. One of the standout benefits is its ability to produce highly intricate designs while maintaining cost-effectiveness. According to a report from Grand View Research, the rubber molding market is expected to reach USD 34.77 billion by 2025, growing at a CAGR of 4.4%. This growth is largely driven by the demand for precision-engineered components in industries such as automotive, aerospace, and medical devices. By leveraging rubber molding techniques, manufacturers can easily create complex geometries that are crucial for high-performance applications, thereby reducing material waste and decreasing the time to market.

Furthermore, rubber molding is notable for its versatility in material selection, allowing manufacturers to tailor the properties of rubber compounds to suit specific applications. A study from the Freedonia Group indicated that specialty rubber demand is projected to grow at 5.5% annually through 2025, influenced by advancements in compounding technology. This capability enables the production of parts resistant to extreme temperatures, chemicals, and environmental conditions, fostering innovations in sectors like oil and gas, where resilience and longevity are paramount. This adaptability not only enhances product reliability but also leads to longer lifecycle management, ultimately benefiting manufacturers and end-users alike.

| Benefit | Description | Applications |

|---|---|---|

| Durability | Rubber components are resistant to wear and tear, ensuring a long service life. | Automotive, Aerospace, Industrial Equipment |

| Flexibility | Rubber molding allows for intricate designs and flexibility in shape and size. | Consumer Goods, Medical Devices, Gaskets |

| Cost-Efficiency | Mass production can lower unit costs, making it budget-friendly. | Construction, Electronics, Prototyping |

| Chemical Resistance | Natural and synthetic rubber can withstand harsh chemicals. | Manufacturing, Oil & Gas, Food Processing |

| Vibration Dampening | Rubber effectively absorbs vibrations, protecting machinery. | Automotive, Machinery Mounts, Electronics |

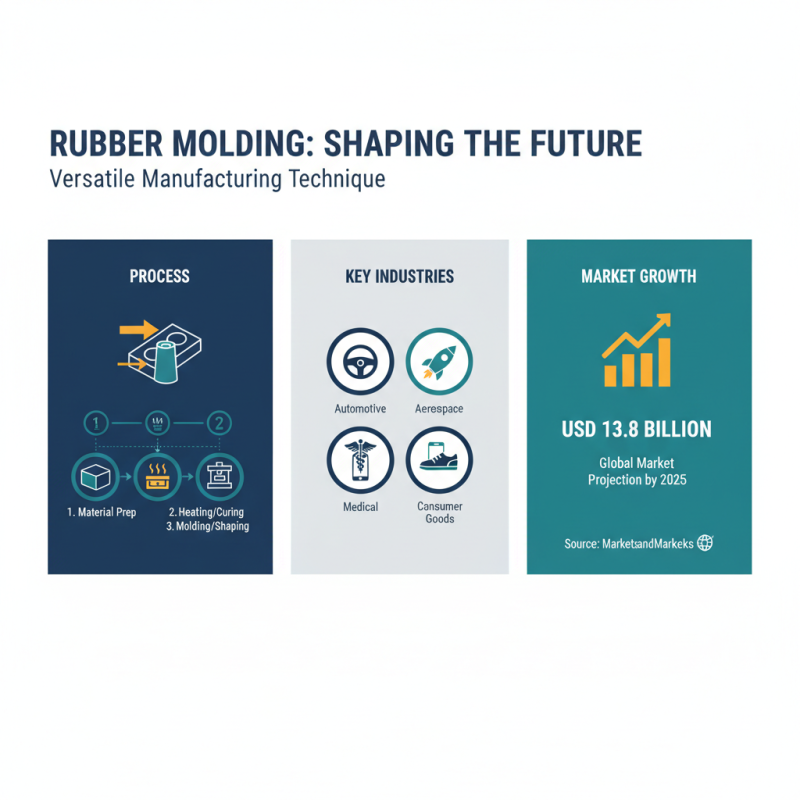

Rubber molding is a versatile manufacturing technique that involves shaping rubber material into specific forms using molds. This process is widely adopted across various industries, including automotive, aerospace, medical, and consumer goods, due to its ability to create durable and flexible parts. According to a report by MarketsandMarkets, the global rubber molding market is projected to reach USD 13.8 billion by 2025, driven by the increasing demand for high-performance materials in manufacturing.

One of the primary advantages of rubber molding is its capacity for mass production, allowing manufacturers to produce large quantities of rubber components quickly and efficiently. The precision ensured through advanced molding technologies results in parts that meet exact specifications, which is crucial in industries like aerospace where safety and reliability are paramount. Furthermore, the customizable nature of rubber molding enables the creation of complex designs and geometries that can enhance the functionality of end products, providing competitive advantages in a fast-evolving market.

In addition, rubber molding can accommodate a range of rubber types, such as silicone, neoprene, and EPDM, each offering unique properties suited for specific applications. For instance, silicone rubber is known for its resistance to extreme temperatures and environmental factors, making it ideal for use in automotive seals and gaskets. As highlighted in a study by Technavio, the increasing focus on sustainability in manufacturing is propelling the innovative use of rubber molding techniques that minimize waste and enhance the recyclability of materials, aligning production processes with modern environmental standards.

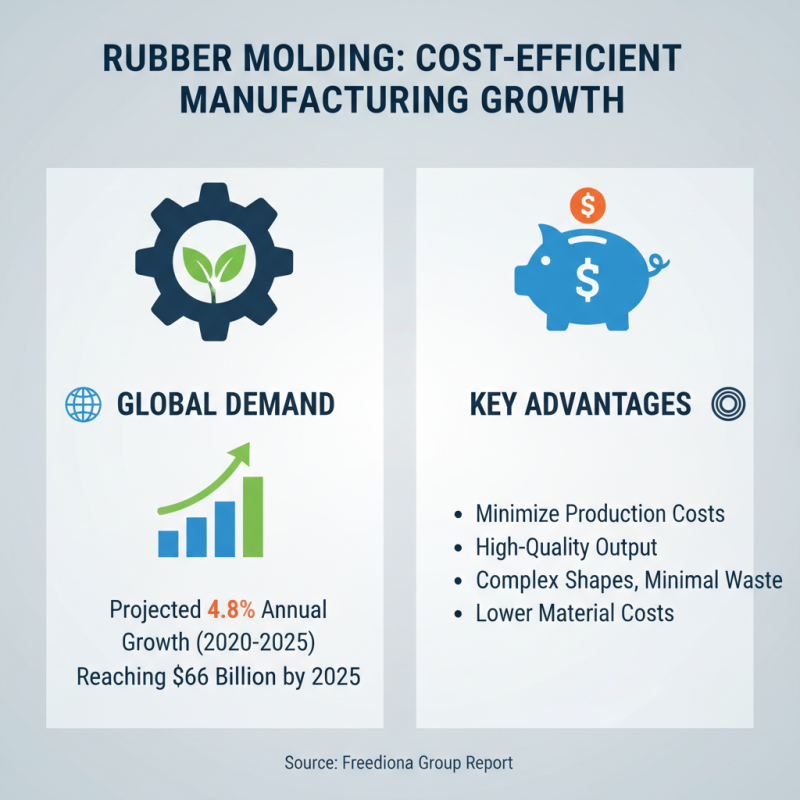

Rubber molding has emerged as a vital process in the manufacturing industry, particularly noted for its cost efficiency. According to a report by the Freedonia Group, the global demand for molded rubber products is projected to grow at a rate of 4.8% annually, reaching nearly $66 billion by 2025. This growth is partly attributed to the ability of rubber molding to minimize production costs while maintaining high-quality output. The versatility of rubber allows manufacturers to produce complex shapes and designs with minimal waste, effectively lowering material costs.

Additionally, rubber molding techniques such as injection molding and compression molding can significantly reduce setup and cycle times. Research from the American Society for Quality reveals that manufacturers can achieve a reduction in overall production time by 15-30% through the use of efficient molding processes. This increase in efficiency not only contributes to lower labor costs but also enables quicker turnaround times, allowing companies to respond rapidly to market demands. As companies strive to optimize their operations, leveraging rubber molding techniques becomes increasingly important for enhancing their cost structure and improving their competitive positioning in the market.

Rubber molding has become a cornerstone in various manufacturing processes due to its remarkable ability to produce durable components. One of the primary advantages of rubber molding is the enhanced longevity of the components it produces. Rubber's natural elasticity and resilience allow molded parts to withstand extreme environmental pressures, from temperature fluctuations to exposure to harsh chemicals. This durability means that components require less frequent replacement, leading to lower long-term costs and minimal downtime in manufacturing operations.

Moreover, the durability of rubber molding components contributes significantly to the overall efficiency of manufacturing processes. Parts that can endure wear and tear without degrading ensure that machinery operates smoothly and reliably over extended periods. This not only fosters productivity but also enhances safety in operations since robust components are less likely to fail abruptly. By choosing rubber molding, manufacturers can benefit from components that offer both performance consistency and longevity, reinforcing the case for integrating rubber into their production lines for a sustainable and efficient future.

Rubber molding has become an essential process in manufacturing, largely due to its impressive customization capabilities. This process allows companies to tailor rubber products specifically to their operational needs, accommodating various functions, sizes, and designs. According to a recent industry report by Grand View Research, the global rubber market is projected to reach over $55 billion by 2025, with a significant portion attributed to custom molded rubber products, highlighting the growing demand for tailored solutions in various sectors, from automotive to industrial machinery.

One of the key advantages of rubber molding is the ability to create intricate designs that meet specific requirements. Manufacturers can choose from an array of rubber compounds and additives to enhance product performance, including durability, flexibility, and heat resistance. For instance, silicone rubber can withstand extreme temperatures, making it ideal for applications in the medical and electronic fields. When businesses leverage these customization options, they not only improve product functionality but also enhance operational efficiency.

**Tips:** When considering custom rubber molding, it’s crucial to engage with your manufacturer early in the design process. This collaborative approach ensures that all necessary specifications are addressed, minimizing costly adjustments down the line. Additionally, reviewing material properties and understanding the production process can lead to better product performance and longevity, ultimately resulting in a more effective manufacturing process.

Rubber Molding is a versatile manufacturing process that offers numerous advantages for various applications. This technique not only enhances cost efficiency by reducing production expenses but also provides durable components with a long lifespan. The customization capabilities of Rubber Molding allow manufacturers to tailor products to meet specific requirements, ensuring that the final output aligns with the unique needs of different industries.

Moreover, Rubber Molding practices are increasingly recognized for their environmental benefits, contributing to more sustainable manufacturing processes. By utilizing eco-friendly materials and methods, manufacturers can reduce their ecological footprint while still achieving high-quality results. Overall, Rubber Molding stands out as an effective solution for modern manufacturing needs, combining efficiency, durability, and sustainability in one innovative approach.