In the realm of industrial applications, the efficiency and reliability of fluid control systems are paramount. One component that stands out for its superior functionality is the Duo-Check Valve. This innovative valve design plays a crucial role in ensuring the unidirectional flow of fluids, thereby preventing backflow and maintaining system integrity. The Duo-Check Valve not only enhances operational safety but also contributes to the overall efficiency of various processes in sectors ranging from manufacturing to water treatment.

The benefits of incorporating Duo-Check Valves into industrial setups are manifold. These valves are engineered to withstand high-pressure environments and are resistant to wear and tear, thus reducing the frequency of maintenance and downtime. Additionally, their lightweight yet durable design makes installation straightforward, facilitating quicker system integrations. As industries continue to evolve and seek out more effective solutions, the Duo-Check Valve emerges as a critical component for enhancing performance and reliability in fluid management systems.

Duo check valves are essential components in industrial applications, primarily used to prevent backflow in piping systems. The functionality of these valves is straightforward yet critical; they utilize two independently operating discs that close under reverse flow conditions, effectively sealing the pipeline and allowing fluid to flow in only one direction. This design not only enhances operational efficiency but also minimizes the risk of contamination, which is particularly vital in industries such as water treatment, pharmaceuticals, and food processing.

According to a report by MarketsandMarkets, the global valve market is projected to reach $86 billion by 2025, with duo check valves recognized for their reliability and durability across diverse applications. The dual-disc design provides a quicker response to changes in flow direction compared to single-disc check valves, reducing the risk of damage to equipment connected downstream. Furthermore, their compact size and lightweight nature allow for easier installation and maintenance, which contributes to reduced operational costs. As industries continue to prioritize efficiency and safety, the role of duo check valves in protecting system integrity becomes increasingly paramount.

| Benefit | Description | Application |

|---|---|---|

| Prevent Backflow | Duo check valves effectively stop the reverse flow of fluids, ensuring operational safety. | Pipelines, Pumps |

| Low Maintenance | They require minimal maintenance due to their sturdy design and simple functionality. | Chemical Processing |

| Compact Design | The compact size allows for easy installation in tight spaces without compromising performance. | Water Treatment, HVAC Systems |

| High Flow Efficiency | Designed to minimize pressure drop and enhance flow rates. | Process Industries |

| Versatility | Can be used with various types of fluids, including gases and liquids. | Oil & Gas, Pharmaceuticals |

Duo check valves are essential components in various industrial systems, offering multiple advantages that enhance operational efficiency and safety. One of the key benefits of these valves is their ability to prevent backflow in pipelines, which can lead to contamination of the fluid being transported. By ensuring a one-way flow, duo check valves help maintain the integrity of the system, protecting both equipment and product quality.

Moreover, duo check valves are designed to minimize pressure loss within the system. Unlike traditional swing check valves, duo check valves utilize a dual disc mechanism that opens and closes more efficiently, allowing for smoother fluid dynamics. This reduced flow resistance translates to lower energy consumption and enhanced performance of pumps and other machinery. Additionally, their compact design makes them suitable for a wide range of industrial applications, from water treatment facilities to chemical processing plants, providing versatility in installation and operation.

In the realm of industrial applications, the choice of check valves plays a pivotal role in ensuring system efficiency and reliability. Duo check valves stand out for their unique design, which typically features two check mechanisms that allow for smooth operation in varying flow conditions. Compared to traditional single-disc check valves, duo check valves offer significant advantages, including reduced pressure drop and increased sealing performance. According to a report by the Flow Control Association, systems utilizing duo check valves can experience up to a 15% increase in efficiency due to their low flow resistance.

When comparing duo check valves to other types, such as ball or swing check valves, the differences in application suitability become apparent. Ball check valves, while effective in some scenarios, can be prone to high-pressure losses and may require greater maintenance. Swing check valves, on the other hand, can be limited by their orientation and susceptibility to water hammer, which could lead to premature wear or failure in certain systems. A study conducted by the American Society of Mechanical Engineers indicates that duo check valves significantly mitigate these issues, making them ideal for high-flow and high-pressure environments often found in industrial settings. This robustness not only enhances operational longevity but also translates to lower lifecycle costs, further solidifying the duo check valve's position as a superior choice in the market.

Duo check valves play a crucial role in a variety of industrial applications, thanks to their unique design that allows for effective backflow prevention. One common application is in the water and wastewater management sector, where they are used to ensure that water flows in the intended direction while preventing contamination and protecting pumps and pipelines from reverse flow. Their reliability in these systems not only enhances operational efficiency but also prolongs the lifespan of equipment.

In the oil and gas industry, duo check valves are equally indispensable. They are employed in pipelines and processing systems to safeguard against backflow, which can lead to costly downtime and safety hazards. These valves help maintain pressure and flow integrity, crucial for operations involving hazardous materials. Additionally, duo check valves are frequently found in heating and cooling systems, where they assist in maintaining optimal flow rates and avoiding system disruptions. By facilitating reliable fluid management across various applications, duo check valves are essential components in the industrial landscape.

This chart illustrates the common applications of Duo Check Valves across various industries, highlighting their benefits in terms of efficiency, reliability, and cost-effectiveness:

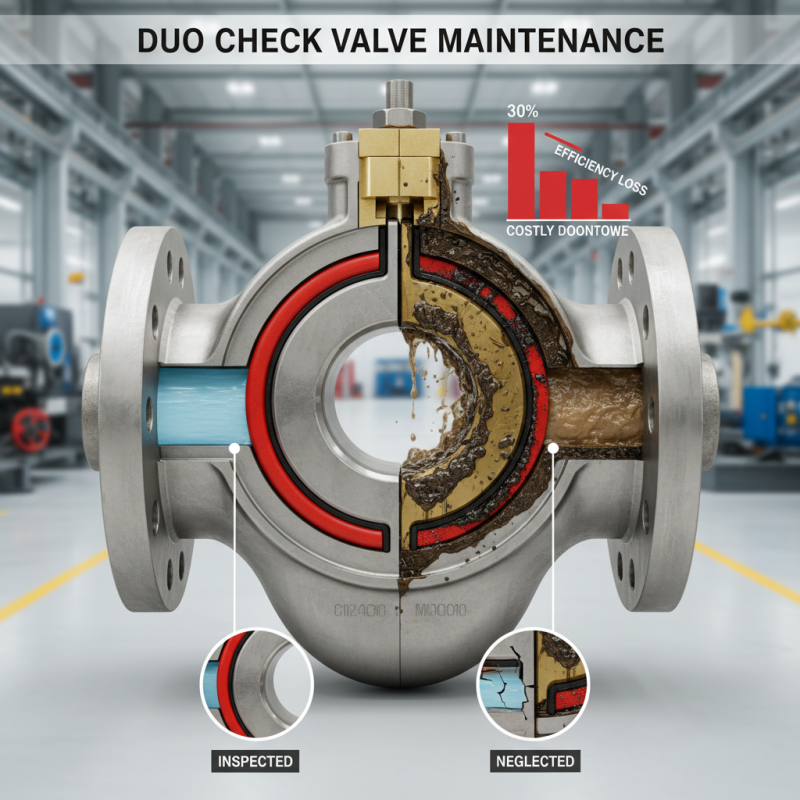

Duo check valves are vital components in various industrial applications, providing an essential function in preventing backflow and maintaining system integrity. To ensure these valves operate efficiently, regular maintenance is crucial. According to the Fluid Power Journal, improper maintenance can reduce valve efficiency by up to 30%, leading to costly downtime and potential damage to machinery. To mitigate such risks, operators should schedule routine inspections to identify wear and tear, particularly in the seals and seats which are often the first components to degrade.

In addition to inspections, the cleaning of duo check valves is equally important. The Institute of Mechanical Engineers emphasizes that debris buildup can severely impact the performance of check valves, causing them to stick or fail. A clean, well-maintained valve can operate at optimal efficiency, minimizing energy consumption and reducing the chances of unexpected failures. Regular flushing of the system and using appropriate cleaning agents can help maintain cleanliness and extend the lifespan of the valves, ensuring they continue to protect the system from backflow effectively. Implementing these maintenance tips not only enhances efficiency but also contributes to the overall safety and reliability of industrial operations.