In the world of fluid control systems, the check valve stands out as a critical component designed to ensure fluid flows in one direction only, preventing backflow and potential damage to pumps and pipelines. As industries continue to evolve and demand more efficient solutions, understanding the intricacies of check valves becomes essential for engineers, operators, and maintenance personnel alike. This 2025 Top Guide to Check Valves is crafted to equip you with everything you need to know about these indispensable devices.

Whether you are a seasoned professional or just beginning to explore the realm of fluid dynamics, this guide breaks down the essential aspects of check valves, including their types, functions, and the principles governing their operation. With insights into selection criteria, maintenance practices, and troubleshooting tips, readers will gain a comprehensive understanding of how to optimize the performance of check valves in various applications. Join us as we delve into the vital role these valves play in safeguarding systems, ensuring operational efficiency, and enhancing overall reliability in fluid handling processes.

Check valves are essential devices in fluid control systems, designed to allow fluid flow in one direction while preventing backflow. This operational attribute is critical in various industries, including oil and gas, water treatment, and HVAC systems. According to a report by Research and Markets, the global check valve market is projected to reach approximately $10 billion by 2025, driven by the increasing demand for efficient fluid management and the expansion of industrial infrastructure.

The primary purpose of a check valve is to maintain the desired flow direction, which helps safeguard pumps and other equipment from damage caused by backflow. In addition to providing protection, check valves contribute to system efficiency by minimizing pressure drops and energy losses. The 2021 Fluid Control Device Market Analysis highlighted that more than 30% of fluid system failures can be attributed to backflow, underscoring the importance of incorporating high-quality check valves in any system design. By effectively handling backpressure and preventing reverse flow, check valves are integral in ensuring the reliability and longevity of various applications.

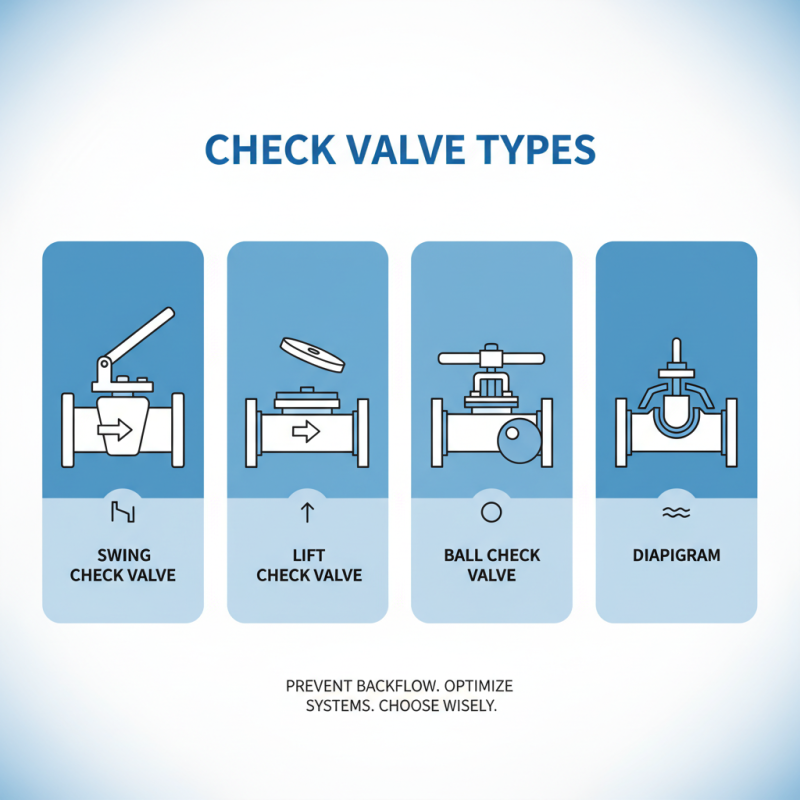

Check valves are essential components in fluid systems, designed to prevent backflow and ensure the efficient operation of various processes. When it comes to selecting the right type of check valve, it’s crucial to understand the key differences between the various options available. The most common types include swing check valves, lift check valves, ball check valves, and diaphragm check valves. Each type has its specific applications, advantages, and limitations, making it important to choose the right one based on the operational needs.

Swing check valves utilize a hinged disc that opens with forward flow and closes when flow reverses, making them suitable for applications with either high or low flow rates. Lift check valves, on the other hand, have a ball or disk that rises to allow flow, delivering better performance at lower pressure drops. For systems requiring a tight seal, ball check valves offer reliability while diaphragm check valves provide a unique feature that can isolate clean water from contaminants.

Tips: When selecting a check valve, consider the fluid type, pressure, and temperature conditions. Always ensure compatibility with existing piping systems to avoid future leaks or failures. Regular maintenance checks can extend the lifespan of these valves, so make it a practice to monitor them closely for any signs of wear or damage.

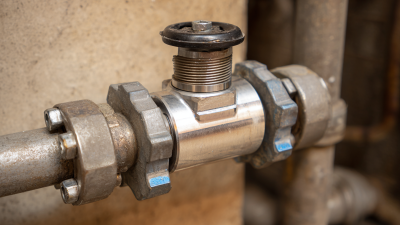

Check valves play an essential role in fluid control systems, ensuring unidirectional flow and preventing backflow. Understanding the key components and design characteristics of these valves is crucial for selecting the right type for a specific application. Typically, check valves consist of a body, a disc, a spring, and sealing components. The body, often made from materials like stainless steel, PVC, or brass, houses the internal mechanisms, while the disc, usually spring-loaded, moves to allow or stop the flow. Reports from the Fluid Control Association indicate that proper sealing can significantly reduce the risk of leaks and enhance system efficiency, with a well-designed check valve minimizing pressure drop across the flow path.

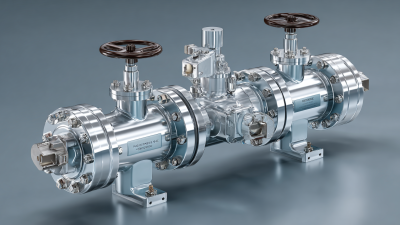

Design characteristics such as the type of valve (swing, lift, or diaphragm) determine their suitability for various applications. For instance, swing check valves are ideal for larger pipelines due to their streamlined design that minimizes turbulence, making them suitable for high-flow scenarios. Conversely, lift check valves are more appropriate for applications with lower flows due to their compact design and reliable sealing capabilities. According to a published market analysis, the global check valve market is projected to grow by over 5% annually through 2025, driven by increased demand in industries like oil and gas, water management, and chemical processing. Understanding these components and characteristics is vital for ensuring system longevity and operational integrity.

This bar chart represents the distribution of key design characteristics of check valves commonly used in industries as of 2025. The data shows the percentage distribution of each characteristic across various designs.

Check valves play a crucial role in various applications across multiple industries by ensuring the unidirectional flow of fluids and preventing backflow. In the water and wastewater treatment industry, check valves are extensively used to protect pumps and equipment from reverse flows that can lead to costly damages and operational inefficiencies. By allowing water to flow in one direction, these valves help maintain system integrity and enhance the reliability of treatment processes.

In the oil and gas sector, check valves are vital for maintaining pressure and preventing the backflow of crude oil and natural gas through pipelines and offshore platforms. Their ability to withstand extreme conditions and high-pressure scenarios makes them indispensable in safeguarding operations. Additionally, in manufacturing and process industries, check valves are used in hydraulic systems and chemical processing to ensure that fluids move in the desired direction without risk of contamination or equipment failure. This widespread utilization underscores their importance in maintaining the efficiency and safety of various industrial processes.

Proper maintenance of check valves is crucial for ensuring their optimal performance and longevity in various industrial applications. According to a report by the American Society of Mechanical Engineers (ASME), inadequate maintenance practices can lead to an increase in operational costs by up to 25% due to valve failures and unplanned downtime. Regular inspection and servicing of check valves can mitigate these risks, and it is recommended that facilities adhere to a maintenance schedule that includes checks for leaks, corrosion, and mechanical wear.

One effective maintenance tip is to implement a routine testing protocol to assess the functionality of the check valves. The Hydraulic Institute recommends conducting annual tests under real operating conditions to evaluate the sealing capability and flow direction. Additionally, facilities should utilize comprehensive data logging to track valve performance trends over time. This data-driven approach not only helps in identifying potential issues early but also supports predictive maintenance strategies that can enhance overall system efficiency. By following these practices, industries can ensure that their check valves operate reliably, contributing to smoother processes and reduced operational costs.